Pololu Blog » Posts tagged “new products” »

Posts tagged “new products” (Page 6)

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

Our newest robot, 3pi+, is here—Arduino-compatible, USB, encoders, full IMU and more!

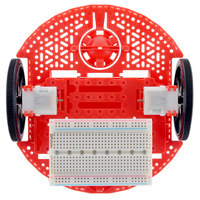

I am thrilled to announce the release of our newest robot, the 3pi+! This new platform is a major upgrade from the original 3pi robot we introduced twelve years ago. At 97 mm, the diameter is just 1mm larger than the original, and the general concept of a tiny, fast robot powered by four AAA batteries and two micro metal gearmotors remains the same. However, just about everything has been redesigned from the ground up to add the extra features everyone has been asking for.

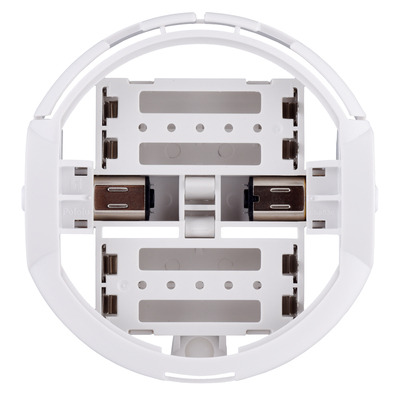

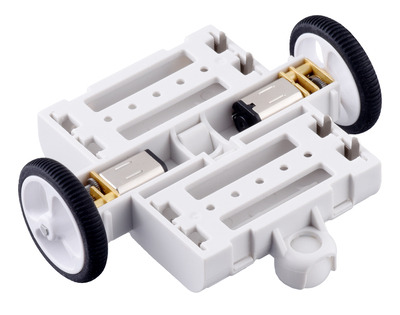

First off, the 3pi+ is now a platform that encompasses a range of products, not just one particular robot. This is enabled primarily by the chassis now being an independent structure rather than being a specific circuit board with motors strapped on:

|

3pi+ Chassis Kit (No Motors or Electronics). |

|---|

|

|

|

|

|

|

The chassis incorporates the battery holders, motor mounts, and ball caster. An outer bumper skirt is removable and the motors can instead be held in by separate clips (also included in the kit). The left-most picture shows the chassis with motors installed but without the bumper skirt or motor clips, and the next two pictures show the motor clips installed:

|

|

|

Making the chassis separate from any electronics means that you can use it with your own electronics and that we can make various versions with different capabilities and microcontrollers.

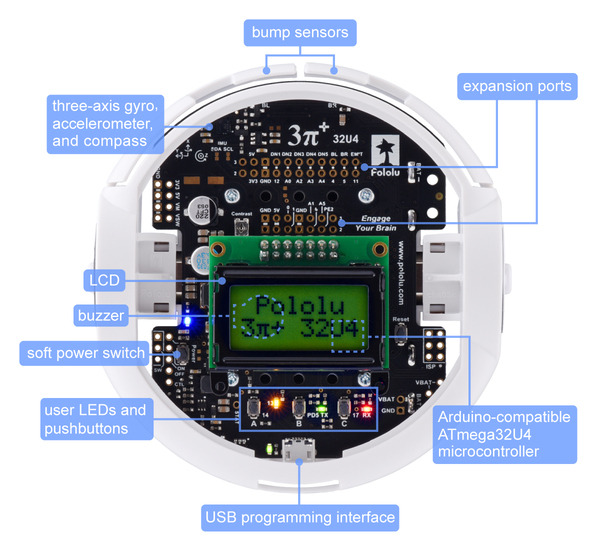

3pi+ 32U4

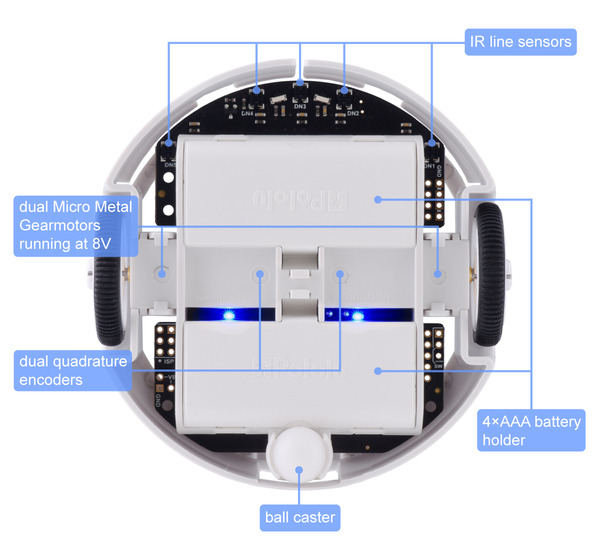

The first full 3pi+ robot we are launching is the 3pi+ 32U4, which is based on an Arduino-compatible ATmega32U4 microcontroller from Microchip (formerly from Atmel). Like the original 3pi, the 3pi+ 32U4 has five integrated downward-looking reflectance sensors, making the robot a great starting point for line following and line-maze events.

The 3pi+ 32U4 offers many major improvements over the original 3pi, including:

- ATmega32U4 microcontroller with Arduino-compatible bootloader can be programmed directly through a USB connection

- Quadrature encoders on both motors for closed-loop position and speed control

- Full 9-axis IMU (three-axis gyro, accelerometer, and compass)

- Bottom-loading battery holders keep batteries accessible even if additional levels are added

- Full wrap-around bumper to protect electronics from collisions

- Two bump sensors on the front

|

3pi+ 32U4 Robot features, top view. |

|---|

|

3pi+ 32U4 Robot features, bottom view. |

|---|

The 3pi+ 32U4 is also available with three motor options for different usage scenarios:

| 3pi+ 32U4 Version | Products | Micro Metal Gearmotor | Top Speed | Comments |

|---|---|---|---|---|

| Standard Edition | assembled or kit | 30:1 MP 6V | 1.5 m/s | great all-around balance between controllability and speed, with top theoretical speed above that of the original 3pi |

| Turtle Edition | assembled or kit | 75:1 LP 6V | 0.4 m/s | longest battery life, easiest to control, appropriate for swarm robot projects or classrooms where you might not want robots flying around the floor (or desktop) too quickly |

| Hyper Edition | assembled or kit | 15:1 HPCB 6V | ~4 m/s | ridiculous speed, which can definitely be fun. But, controlling that speed can be difficult, which can make the robot more prone to self-destruction (or at least self-inflicted damage), so we recommend this only for advanced users |

These three 3pi+ 32U4 motor options are available in assembled or kit form, and for those who want to do your own thing, the parts are available separately so that you can pick some other motor or gear ratio.

Normally we would have an introductory special for this big of a new product release, but since we are about to launch our annual Black Friday and Cyber Monday sale, you can get a great discount on the new 3pi+ there!

New product: VL53L3CX Time-of-Flight Multi-Target Distance Sensor Carrier

December 2020 update: ST originally specified a 3 m (10 ft) maximum range for the VL53L3CX, and we initially released this product with the name “VL53L3CX Time-of-Flight Multi-Target Distance Sensor Carrier with Voltage Regulator, 300cm Max”. However, they have since released an updated API with software improvements that increase the maximum range to 5 m (16 ft), so we have updated the name of this product accordingly. The latest version of the API should enable this increased range on existing boards as well as new ones; the hardware has not changed.

Please note that the rest of this post has not been updated to reflect the increased 5 m range (which now exceeds the VL53L1X’s 4 m range).

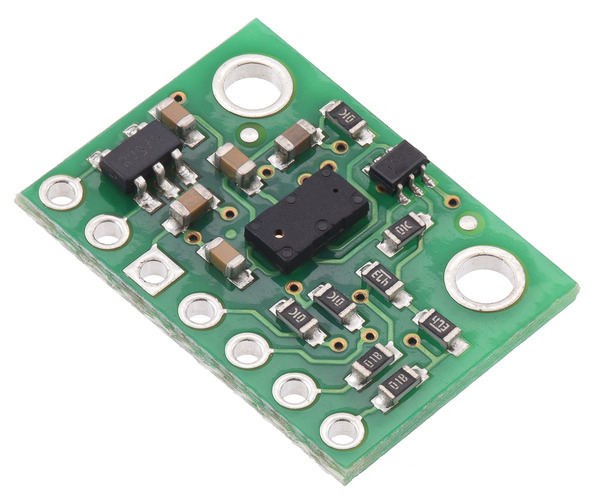

We are now offering a VL53L3CX Time-of-Flight Multi-Target Distance Sensor Carrier. The VL53L3CX is one of ST’s latest ranging sensors featuring their FlightSense technology, which determines distance by measuring how long it takes for emitted light to be reflected from a target and arrive back at the sensor. It can work at distances of up to 3 m, putting the VL53L3CX’s effective range in between those of ST’s older VL53L1X and VL53L0X integrated lidar modules.

Beyond just being an intermediate option, the VL53L3CX is interesting because it has the ability to detect multiple targets within its field of view. This is possible because instead of picking out a single distance based on the reflections received by the sensor, the VL53L3CX outputs histogram data representing how much reflected light it is receiving within different time intervals. The host processor can then read this data through a digital I²C interface and analyze it using special algorithms that ST provides as part of their VL53L3CX API.

This enhanced capability does come at a cost: the added complexity of the histogram processing means that the host requires much more RAM and program memory, making the VL53L3CX difficult to use with small microcontrollers. In our testing, we were unable to fit the VL53L3CX API on a typical 8-bit Arduino, and we are not providing an Arduino library to support the VL53L3CX; therefore, we recommend sticking with the VL53L1X or VL53L0X for applications with similar constraints. However, if you have more resources available on something like a 32-bit processor, the VL53L3CX’s multi-target detection might give you valuable information beyond what you could determine from a distance reading alone.

For more information about the VL53L3CX carrier, see its product page. The first 100 customers can use VL53L3CXINTRO to get up to 7 units for just $7.77 each!

First new products under emergency operations - new servo wheels!

We are into May, and after almost 8 weeks of shutdowns and emergency operations, most of the world’s attention seems to be moving toward reopening and how to return to some semblance of normal, or at least longer-term sustainable operations. With no particular medical solution even on the horizon, it’s clear that we have a long way to go, and a city like Las Vegas is going to be hurt especially hard and for a long time by changes people will adopt until they are comfortable flying for fun again. Pololu has managed to hold up much better than I initially feared during the first week of mandated shutdowns, and I am especially grateful to all of our customers and staff members who have worked hard to get us this far.

It is with this backdrop of gratitude for making it this far while realizing we still have a long way to go that I am especially excited to announce our first new products released since the pandemic hit!

|

|

|

|

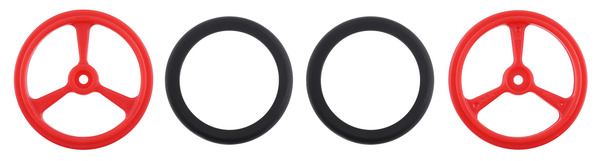

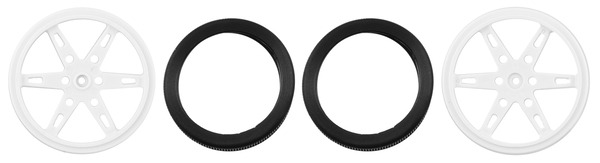

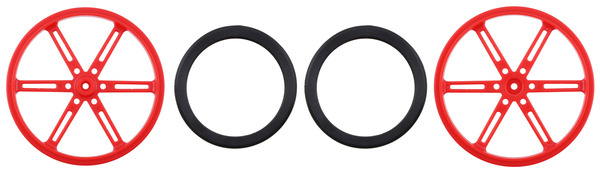

In all, we have eight new wheels for micro and standard sized servos. These are red and white versions of the four sizes we released in black back in January. Since we are operating with a minimum staff on site, we don’t have many actual pictures of the new wheels in action, so I will use the pictures with older black wheels for the rest of the post.

|

Black Pololu Wheels for Standard and Micro Servos – 90, 70, 60, and 40 mm diameters. |

|---|

|

We have small, 40 mm and 60 mm sizes that are compatible with micro servo splines with 20 teeth and a 4.8 mm diameter and can be used with the following continuous rotation servos that we carry:

- FEETECH FS90R Micro Continuous Rotation Servo

- FEETECH FT90R Digital Micro Continuous Rotation Servo.

|

We have larger 70 mm and 90 mm sizes that are compatible with standard servo splines with 25 teeth and a 5.8 mm diameter and can be used with the following continuous rotation servos we carry:

- FEETECH Continuous Rotation Servo FS5106R

- Power HD Continuous Rotation Servo AR-3606HB

- SpringRC SM-S4303R Continuous Rotation Servo

- Parallax Feedback 360° High-Speed Servo

If you plan on using the wheels with a servo not listed above, be sure to check your servo’s specifications for compatibility as servo splines are not standardized.

I was never especially fond of continuous-rotation servos, but there’s no denying that they’re often a quick and relatively simple way to get something moving, both from the electronics side (since the motor controller is built into the servo) and the software side. I am a fan of building your own unique robots, so I am happy we now have a range of size and color choices to give you more problem-solving options and variety in your robots.

Like many of our plastic products, these wheels were designed by us in Las Vegas and then injection molded in China. Since we already had the design and molds finished before we released the black versions, these new products are not the most new from a design perspective. We made the black ones first, and red and white were supposed to follow shortly after the Chinese New Year holiday. As we all got reminded, things don’t always go according to plan. And now, what should have been a minor new product has additional sentimental meaning as our first new product since the coronavirus upended our lives and a symbol of our determination to carry on.

We had been announcing new products along with introductory discounts for the last few years, and I wavered for a bit about doing extra discounts for these wheels. Shipping costs have gone up dramatically, and we’re trying to raise whatever money we can, so extra discounts are not the first thing I felt like doing. But the whole point is that we do want to celebrate at least a little! So, hooray for the continuation of the new product discount tradition:

The first hundred customers to use coupon code SERVOWHEELS can get 22% off up to 3 pairs of each size! And, if you are one of the lucky ones not especially financially hurt by the pandemic and are interested in these wheels, please consider getting them without the coupon or even donating to help Pololu keep operating. We have set up item 2400 for donating in $1 increments.

Thank you to all of you who have donated to us or otherwise supported us over the past two months. Stay safe and healthy, everybody!

New products: Pololu Wheels for Micro and Standard Servos

We are thrilled to announce the release of our wheels for micro and standard sized servos. These wheels are similar to our wheels for 3mm D shafts and consist of a durable ABS hub with a silicone tire. They are currently available in 40, 60, 70, and 90 mm diameter options. All but the 40 mm size feature mounting holes that are compatible with various versions of our universal mounting hubs and slots in the spokes that allow additional accessories to be mounted to the wheel such as decorations or parts of an encoder system.

|

Black Pololu Wheels for Standard and Micro Servos – 90, 70, 60, and 40 mm diameters. |

|---|

|

The 40 mm and 60 mm sizes are compatible with micro servo splines with 20 teeth and a 4.8 mm diameter and can be used with the following continuous rotation servos that we carry:

- FEETECH FS90R Micro Continuous Rotation Servo

- FEETECH FT90R Digital Micro Continuous Rotation Servo.

|

The 70 mm and 90 mm sizes are compatible with standard servo splines with 25 teeth and a 5.8 mm diameter and can be used with the following continuous rotation servos that we carry:

- FEETECH Continuous Rotation Servo FS5106R

- Power HD Continuous Rotation Servo AR-3606HB

- SpringRC SM-S4303R Continuous Rotation Servo

- Parallax Feedback 360° High-Speed Servo

If you plan on using the wheels with a servo not listed above, be sure to check your servo’s specifications for compatibility as servo splines are not standardized for particular sized servos.

These wheels, like many of our plastic parts, are designed by us at our Las Vegas facility and then injection molded in China. Usually, we ship bulkier parts made overseas by boat, which can take several months to get here. We were so excited about these, though, that we couldn’t wait that long! So, we had a small amount shipped by air to make them available as soon as possible. This means the initial stock of these is limited, and while we’ll have more coming by boat, the upcoming Chinese New Year will delay that even more than usual. So if you don’t want to miss out on these initial units, order yours soon!

Introductory special

As usual, we are offering an extra introductory special discount on these wheels, to help share in our celebration of releasing new products. The first hundred customers to use coupon code SERVOWHEELS can get 22% off up to 3 pairs of each size!

New products: 24V 37D Metal Gearmotors

|

We are excited to share that we have expanded our line of 37D Metal Gearmotors to include 24 V options. These brushed DC gearmotors are the largest and most powerful we carry, measuring 37 mm (1.46″) in diameter. They are available in gear ratios ranging from 6.3:1 to 150:1 and with or without integrated 64 CPR quadrature encoders on the motor shafts. The 12 V and 24 V motors offer approximately the same performance at their respective nominal voltages, with the 24 V motor drawing half the current of the 12 V motor. The table below summarizes all of the options we now have available. Please see our newest revision of the 37D metal gearmotor datasheet (2MB pdf) for the full specifications and performance graphs for all the options.

| Rated Voltage |

Stall Current |

No-Load Current |

Gear Ratio | No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Without Encoder |

With Encoder |

|

|---|---|---|---|---|---|---|---|---|---|

| (kg ⋅ cm) | (oz ⋅ in) | ||||||||

| 12 V | 5.5 A | 0.2 A | 1:1 (no gearbox) | 10,000 | 0.5 | 7 | – | – | item #4750 |

| 6.3:1 | 1600 | 3.0 | 42 | 12 | item #4747 | item #4757 | |||

| 10:1 | 1000 | 4.9 | 68 | 12 | item #4748 | item #4758 | |||

| 19:1 | 530 | 8.5 | 120 | 12 | item #4741 | item #4751 | |||

| 30:1 | 330 | 14 | 190 | 12 | item #4742 | item #4752 | |||

| 50:1 | 200 | 21 | 290 | 10 | item #4743 | item #4753 | |||

| 70:1 | 150 | 27 | 380 | 10* | item #4744 | item #4754 | |||

| 100:1 | 100 | 34 | 470 | 8* | item #4745 | item #4755 | |||

| 131:1 | 76 | 45 | 630 | 6* | item #4746 | item #4756 | |||

| 150:1 | 67 | 49 | 680 | 6* | item #2829 | item #2828 | |||

| 24 V | 3 A | 0.1 A | 1:1 (no gearbox) | 10,000 | 0.55 | 8 | – | – | item #4690 |

| 6.3:1 | 1600 | 3.5 | 49 | 14 | item #4688 | item #4698 | |||

| 10:1 | 1000 | 5.5 | 76 | 14 | item #4689 | item #4699 | |||

| 19:1 | 530 | 9.5 | 130 | 13 | item #4681 | item #4691 | |||

| 30:1 | 330 | 15 | 210 | 13 | item #4682 | item #4692 | |||

| 50:1 | 200 | 23 | 320 | 12 | item #4683 | item #4693 | |||

| 70:1 | 140 | 31 | 430 | 10* | item #4684 | item #4694 | |||

| 100:1 | 100 | 39 | 540 | 8* | item #4685 | item #4695 | |||

| 131:1 | 79 | 47 | 650 | 6* | item #4686 | item #4696 | |||

| 150:1 | 68 | 56 | 780 | 6* | item #4687 | item #4697 | |||

| * Output power for these units is constrained by gearbox load limits; spec provided is output power at max recommended load of 10 kg⋅cm. | |||||||||

Note: The listed stall torques and currents are theoretical extrapolations; units will typically stall well before these points as the motors heat up. Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. The recommended upper limit for continuously applied loads is 10 kg-cm (150 oz-in), and the recommended upper limit for instantaneous torque is 25 kg-cm (350 oz-in). Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

New products: D36V50Fx Step-Down Voltage Regulators

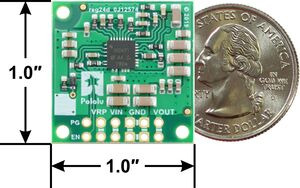

We have a new set of regulators to announce: the D36V50Fx family of step-down voltage regulators. Measuring a compact 1″ × 1″, these regulators support input voltages up to 50 V and can typically deliver around 5 A of current, although some versions can output much more under certain conditions.

|

Step-Down Voltage Regulator D36V50Fx, bottom view with dimensions. |

|---|

The family consists of six fixed output voltage versions between 3.3 V and 12 V:

- D36V50F3: Fixed 3.3V output

- D36V50F5: Fixed 5V output

- D36V50F6: Fixed 6V output

- D36V50F7: Fixed 7.5V output

- D36V50F9: Fixed 9V output

- D36V50F12: Fixed 12V output

We can also manufacture a customized version for you here in our Las Vegas facility. For example, we could make regulators with a different output voltage that your project needs, or we could replace the 40 V reverse voltage protection MOSFET with a 20 V one for slightly improved efficiency if your input voltage will always be lower than 20 V. If you are interested in customization, please contact us for more information.

Comparison to other regulators

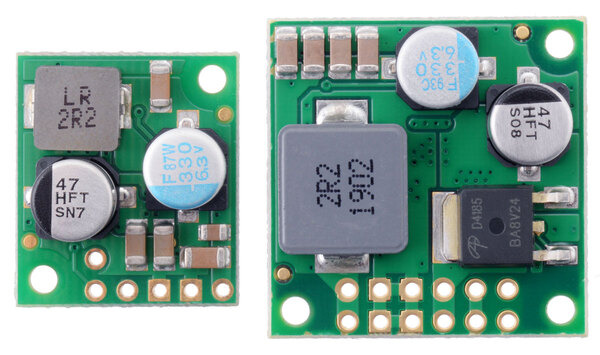

|

D36V28Fx and D36V50Fx Step-Down Voltage Regulators. |

|---|

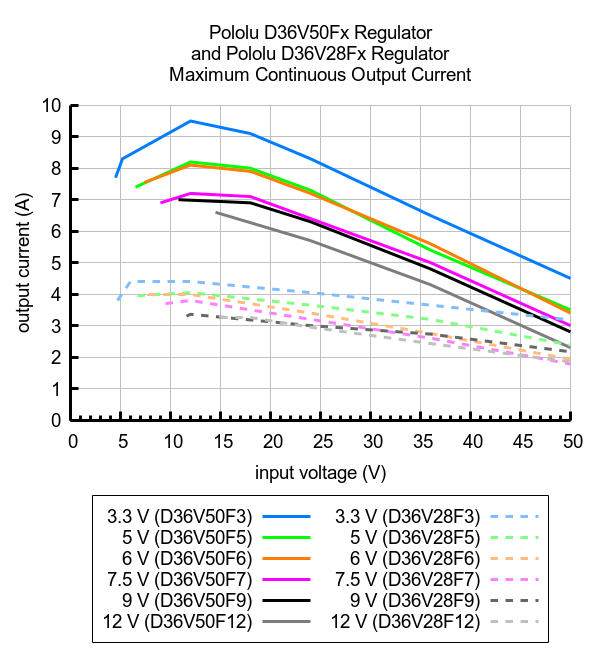

The D36V50Fx regulators are larger and more powerful counterparts to the D36V28Fx family we introduced last year, with the same input voltage ranges and mostly similar characteristics. What distinguishes the two families in performance is that the D36V50Fx regulators can provide roughly double the output current! (At the high end of the input voltage range, the difference is generally less dramatic.)

|

Comparison of the maximum continuous current of Step-Down Voltage Regulators D36V50Fx and D36V28Fx. |

|---|

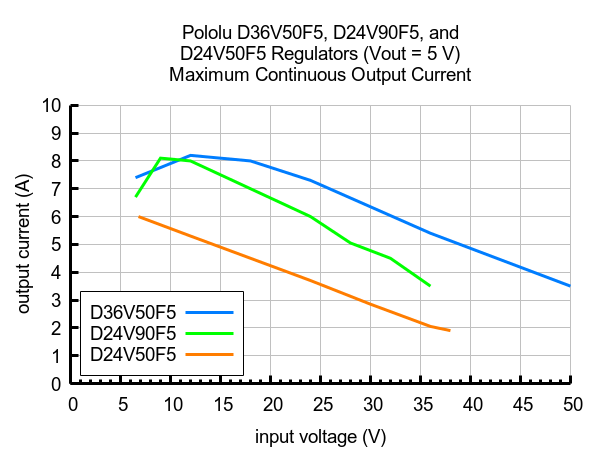

And since many of our most popular regulators are 5 V modules, here is a graph comparing the new D36V50F5 (in blue) with two of our older high-power regulators, the D24V90F5 and the D24V50F5:

|

Comparison of the maximum continuous current of 5V Step-Down Voltage Regulators D36V50F5, D24V90F5, and D24V50F5. |

|---|

Introductory special

As usual, we are offering an extra introductory special discount on these new regulators, to help share in our celebration of releasing a new product. The first hundred customers to use coupon code D36V50FXINTRO can get up to 3 units of each version for just $11.95 each!

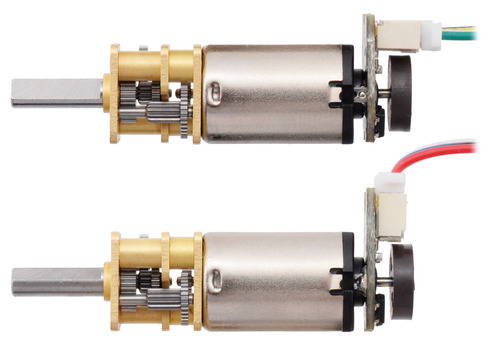

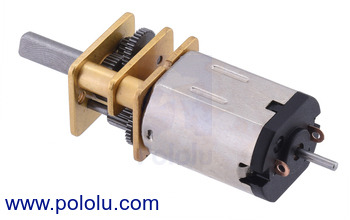

New products: micro metal gearmotors with 15:1 gear ratio

|

We have expanded our line of micro metal gearmotors to include versions with a 15:1 gear ratio. As with all of our other micro metal gearmotors, these units are available with five different motor options:

|

- Motors with precious metal brushes

- Motors with longer-life carbon brushes (HPCB)

Each motor is available with or without an extended back shaft, which rotates at the same speed as the input to the gearbox and offers a way to add an encoder, such as our encoders for micro metal gearmotors (see the picture above). This makes ten new versions in all:

| Rated Voltage |

Motor Type |

Stall Current (A) |

No-Load Current (A) |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Single-Shaft (Gearbox Only) |

Dual-Shaft (Gearbox & Motor) |

|

|---|---|---|---|---|---|---|---|---|---|

| (kg ⋅ cm) | (oz ⋅ in) | ||||||||

| 12 V | high-power, carbon brushes (HPCB) |

0.75 | 0.06 | 2200 | 0.25 | 3.5 | 1.4 | 15:1 HPCB 12V | 15:1 HPCB 12V dual-shaft |

| 6 V | high-power, carbon brushes (HPCB) |

1.5 | 0.10 | 2100 | 0.25 | 3.5 | 1.3 | 15:1 HPCB 6V | 15:1 HPCB 6V dual-shaft |

| 6 V | high-power (HP) |

1.6 | 0.07 | 2000 | 0.30 | 4.2 | 1.5 | 15:1 HP 6V | 15:1 HP 6V dual-shaft |

| 6 V | medium-power (MP) |

0.67 | 0.04 | 1400 | 0.20 | 2.8 | 0.70 | 15:1 MP 6V | 15:1 MP 6V dual-shaft |

| 6 V | low-power (LP) |

0.36 | 0.02 | 860 | 0.17 | 2.4 | 0.37 | 15:1 LP 6V | 15:1 LP 6V dual-shaft |

More detailed specifications for all our micro metal gearmotors can be found in their datasheet (5MB pdf).

These new versions bring our total micro metal gearmotor selection to 130 options, with gear ratios ranging from 5:1 to 1000:1! To see them all, visit our micro metal gearmotor category, and visit our metal gearmotor category to see all of our metal gearmotor options. Keep in mind if you don’t see an option that suits your application, for sufficient volumes, modifications such as customized output shafts are available.

Once you find the perfect gearmotors for your project, don’t forget to check out our great selection of accessories. These were all designed either specifically for our micro metal gearmotors or with their compatibility in mind:

- Wheels and tracks

- Universal mounting hubs with #2-56, #4-40, or M3 holes.

- 12mm Hex Wheel Adapter for 3mm Shaft

- Mounting brackets in white, black, or extended options

- Magnetic and optical encoders

|

|

|

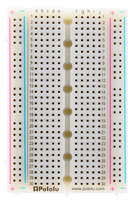

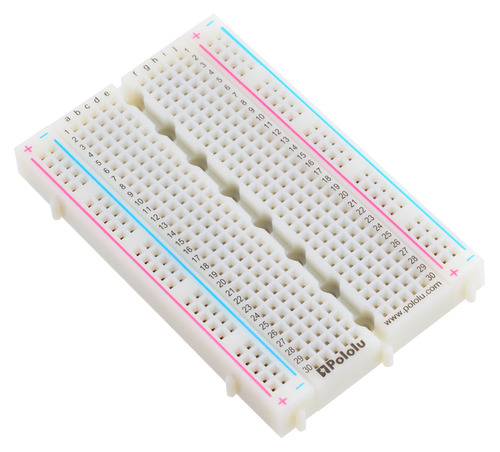

New product: Pololu 400-Point Breadboard with Mounting Holes

|

What’s this? A 400-Point breadboard with mounting holes! We know you’ve been waiting for this your whole life.

Okay, maybe not. But hey, mounting holes are awesome, and now you can pick up some of our new 400-point breadboards and mount them all over the place!

This 3.2″ × 2.1″ breadboard is fairly standard in many ways. It has four bus lines spanning the length of the board and 30 rows of pins, enough for up to four 14-pin DIP ICs or three 16-pin DIP ICs. The rows and columns of tie points are conveniently labeled, multiple units can be connected for larger projects, and it has an adhesive backing for those of you who like sticking breadboards on things.

|

|

But this breadboard is also a little special. It has eight mounting holes for M2 or #2 screws spaced evenly down the center on a 1 cm pitch. Now you can do stuff like mount your breadboard to a Romi Chassis (or any robot chassis) with some standoffs like this:

|

|

|

Wow! So convenient! And they’re just $2.49 each! But, even better, we’ve got a special discounted price for the first hundred customers. Get up to 10 boards at just $1.75 each using coupon code 400PTBBINTRO!

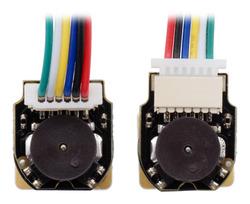

New products: Magnetic Encoder Pair Kit with JST SH-type Connectors for Micro Metal Gearmotors

|

Everyone wants encoders on their motors, but not everyone wants to solder a bunch of wires to a tiny encoder board. That is why I am excited to announce that we are now offering two new versions of magnetic encoders for Micro Metal Gearmotors that feature JST SH-type connectors:

- Magnetic Encoder Pair Kit with Top-Entry Connector for Micro Metal Gearmotors, 12 CPR, 2.7-18V

- Magnetic Encoder Pair Kit with Side-Entry Connector for Micro Metal Gearmotors, 12 CPR, 2.7-18V

These encoders are easier to get up and running than our previous design that requires soldering to through-holes with a 2 mm pitch. With these new encoders, you just have to solder the board to the two motor tabs (sorry, that part is not going away yet), put the magnetic disc on the backshaft, and plug in your cable (available separately in a variety of lengths)!

We think that the “micro” aspect of our Micro Metal Gearmotors is one of their coolest features since their small size make them useful in a wide array of projects. We designed these encoders with this in mind, making them within the profile of the gearmotor on three sides (the side with the connector extends a few millimeters past the motor). Since everyone’s constraints are different, we decided to make two encoder versions, one with a top-entry connector that lets the cable come straight out of the back, and one with a side-entry connector for applications where there isn’t much space past the rear of the motor. We are also continuing to offer encoder boards with through-holes, which allow wires to be soldered to the board for especially compact installations.

|

|

Remember that you will also need 6-pin female JST SH-style cables to use our new encoders. We are offering those cables in three lengths: 12 cm, 30 cm, and 75 cm.

|

The ends of our cables are unterminated so you can decide how you want to connect them in your project (solder, crimp connectors, terminal blocks, etc.).

Introductory special

In case you are not as excited as I am yet, our intro special might help. Right now, you can get up to five of our new encoder pair kits for just $4.95 each using the coupon code MMGMENCINTRO! (Click to add the coupon code to your cart.) But you better hurry, this offer is limited to the first hundred customers to use the coupon code.

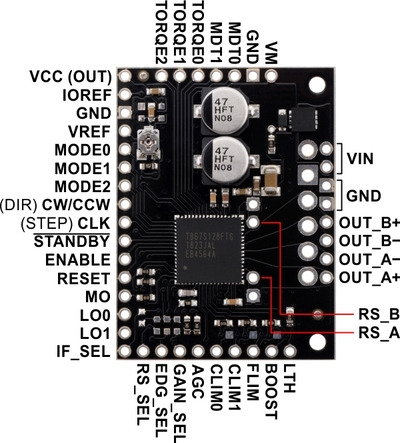

New product: Toshiba TB67S128FTG stepper driver carrier

Our wide selection of stepper motor drivers has grown once again, this time with the addition of a full breakout board for Toshiba’s TB67S128FTG. The TB67S128FTG has many of the same great innovative features as the TB67S2x9FTG carriers we released last year, including Active Gain Control (AGC) for automatically reducing the current when full torque is not needed and Advanced Dynamic Mixed Decay (ADMD) for smoother, more even microsteps. On top of that, it adds features such as microstepping down to 1/128th-step and an optional serial interface. The driver offers a wide operating voltage range of 6.5 V to 44 V, and it can deliver 2.1 A per phase continuous (5 A peak) on our carrier board without any heat sink or forced air flow, making it our highest-current integrated driver (bested only by our discrete MOSFET High-Power Stepper Motor Driver 36v4).

These stepper motor driver carriers first debuted at Toshiba’s booth at Maker Faire Tokyo in August, and now that we finally have the drivers in volume, we are able to offer them to you! All of the driver’s control pins and outputs are available, so it can function as a complete evaluation board for the TB67128FTG, yet it is compact enough to integrate into actual projects without taking up an excessive amount of space:

|

TB67S128FTG Stepper Motor Driver Carrier, top view with labeled pinout. |

|---|

Introductory special

As with all of our new product announcements, we are offering an introductory discount to make it extra easy to try out this new driver. Be among the first 100 customers to use coupon code TB67S128INTRO (click to add the coupon code to your cart) and up to three units for just $7.95 each.