Pololu Blog » Posts tagged “new products” »

Posts tagged “new products” (Page 7)

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

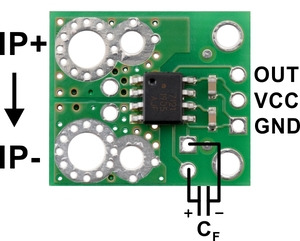

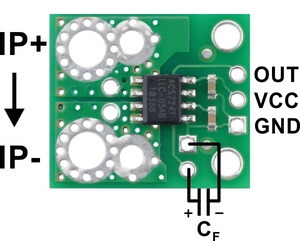

New products: ACHS-7124/7125 current sensor carriers

|

We have expanded our line of Hall effect-based linear current sensors from Broadcom to include ±40 A and ±50 A versions. These easy-to-use bidirectional current sensors are now available in five current range options:

- ACHS-7121 Current Sensor Carrier -10A to +10A

- ACHS-7122 Current Sensor Carrier -20A to +20A

- ACHS-7123 Current Sensor Carrier -30A to +30A

- ACHS-7124 Current Sensor Carrier -40A to +40A

- ACHS-7125 Current Sensor Carrier -50A to +50A

With these additions, our full line of current sensors now includes 15 options with current and sensitivity ratings ranging from ±5 A with 400 mV/A sensitivity to ±75 A with 28 mV/A sensitivity. The following table shows all of current sensor options:

ACS709 Current Sensor Carrier |

ACS711EX Current Sensor Carriers |

ACS714 Current Sensor Carriers |

ACS724 Current Sensor Carriers |

ACHS-712x Current Sensor Carriers |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sensor IC: | ACS709 | ACS711EX | ACS714 | ACS724 | ACHS-712x | ||||||

| Current range / sensitivity(1): | ±75 A / 28 mV/A | ±15.5 A / 136 mV/A ±31 A / 68 mV/A |

±5 A / 185 mV/A ±30 A / 66 mV/A |

0–10 A / 400 mv/A 0–30 A / 133 mV/A ±5 A / 400 mV/A ±20 A / 100 mV/A ±50 A / 40 mV/A |

±10 A / 185 mV/A ±20 A / 100 mV/A ±30 A / 66 mV/A ±40 A / 50 mV/A ±50 A / 40 mV/A |

||||||

| Path resistance: | 1.1 mΩ | 0.6 mΩ | 1.2 mΩ | 1.2 mΩ | 0.7 mΩ | ||||||

| Bandwidth | 120 kHz | 100 kHz | 80 kHz | 120 kHz | 80 kHz | ||||||

| Vcc range:(1) | 3 V–5.5 V | 3 V–5.5 V | 4.5 V–5.5 V | 4.5 V–5.5 V | 4.5 V–5.5 V | ||||||

| Size: | 0.82″ × 0.9″ | 0.7″ × 0.8″ | 0.7″ × 0.8″ | 0.7″ × 0.8″ | 0.7″ × 0.8″ | ||||||

| Special features: | configurable over-current threshold, low-voltage operation, high bandwidth |

over-current fault pin, low-voltage operation |

Differential Hall sensing rejects common-mode fields, high bandwidth |

||||||||

| 1-piece price: | $5.95 | $4.85 | $19.95 | $9.95 | $6.95 | ||||||

| 1 Sensitivity based on when Vcc is 5V. | |||||||||||

Introductory special

As usual, we are offering an extra introductory special discount on the ACHS-712x current sensor carriers, to help share in our celebration of releasing a new product. The first hundred customers to use coupon code ACHSINTRO can get up to five units for just $3 each!

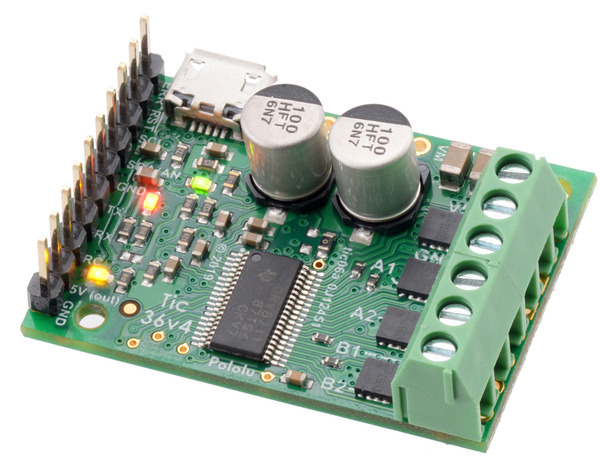

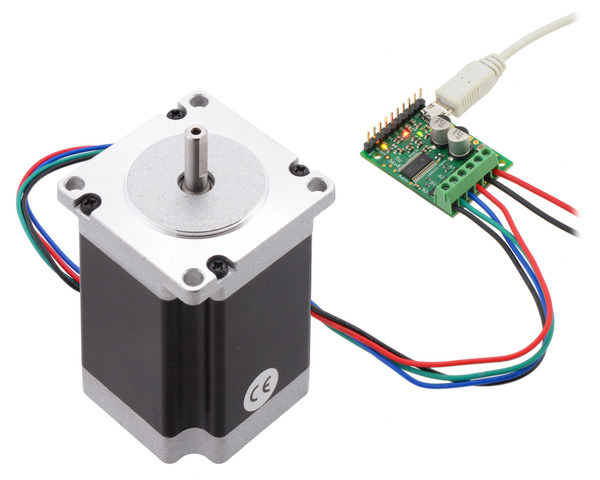

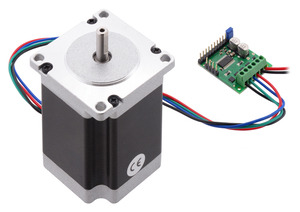

New product: Tic 36v4 USB Multi-Interface High-Power Stepper Motor Controller

I am pleased to announce the release of the Tic 36v4 USB Multi-Interface High-Power Stepper Motor Controller, the fifth model in our line of Tic Stepper Motor Controllers. The Tic 36v4 features a discrete MOSFET stepper motor driver that can deliver up to approximately 4 A per phase, without a heat sink or forced air flow, over a broad 8 V to 50 V operating range. With the ability to provide more than twice as much current as any of our previous stepper motor controllers, this is our highest-power Tic yet, and the first that can drive the most demanding stepper motors we carry (#1474 and #1478) with their full rated current (2.8 A).

|

Tic 36v4 USB Multi-Interface High-Power Stepper Motor Controller controlling a #1478 stepper motor from USB. |

|---|

The Tic 36v4 supports microstepping resolutions down 1/256 step, which is 8 times smaller than any previous Tic model. These new, finer microstep resolutions make it increasingly important to be able to take steps at a high speed since with microsteps that small, it takes up to 51,200 of them to complete one revolution on standard stepper motors with 200 full steps per revolution. The Tic firmware takes care of that for you: it is designed to be able to produce up to 50,000 steps per second, meaning that you can get 58 RPM out of most of our stepper motors even when using 1/256 step mode. Every power of two step mode between full stepping and 1/256 is supported, allowing you to choose the right trade-off between speed and resolution.

|

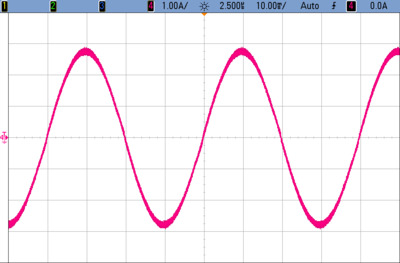

An oscilloscope capture showing the current through one coil of a stepper motor as the Tic 36v4 takes 25600 microsteps per second in 1/256 step mode. |

|---|

By default, the Tic 36v4 uses an automatic mixed decay mode for current regulation. In this mode, it dynamically selects between fast or slow decay based on the actual coil current, allowing it to achieve extremely smooth stepping in most applications without a lot of manual tuning—especially at high microstepping resolutions. (Isn’t that a nice sine wave in the picture above?)

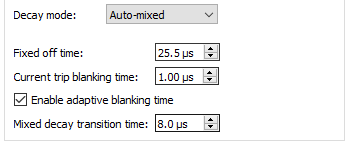

However, if you want more control, this Tic also gives you the option to select a fixed decay mode and adjust several timing parameters to fine-tune the current decay behavior. This can be easily done with the Tic’s free graphical configuration software.

|

The decay mode settings for the Tic 36v4 in the Tic Control Center software. |

|---|

Like the other members of the Tic family, the Tic 36v4 makes basic speed or position control of a stepper motor easy, with lots of configurable parameters (e.g. max speed and acceleration) and support for six high-level control interfaces:

- USB for direct connection to a computer

- TTL serial operating at 5 V for use with a microcontroller

- I²C for use with a microcontroller

- RC hobby servo pulses for use in an RC system

- Analog voltage for use with a potentiometer or analog joystick

- Quadrature encoder input for use with a rotary encoder dial, allowing full rotation without limits (not for position feedback)

|

This video gives a brief demonstration of these interfaces in action:

The Tic 36v4 is available with connectors soldered in or without connectors soldered in. If you do not need the high-level interfaces provided by the Tic, we also offer the Pololu High-Power Stepper Motor Driver 36v4.

Here is a handy comparison chart with all five Tic stepper motor controllers:

Tic T500 |

Tic T834 |

Tic T825 |

Tic T249 |

Tic 36v4 |

|

|---|---|---|---|---|---|

| Operating voltage range: | 4.5 V to 35 V(1) | 2.5 V to 10.8 V | 8.5 V to 45 V(1) | 10 V to 47 V(1) | 8 V to 50 V(1) |

| Max continuous current per phase (no additional cooling): |

1.5 A | 1.5 A | 1.5 A | 1.8 A | 4 A |

| Peak current per phase (additional cooling required): |

2.5 A | 2 A | 2.5 A | 4.5 A | 6 A |

| Microstep resolutions: | full half 1/4 1/8 |

full half 1/4 1/8 1/16 1/32 |

full half 1/4 1/8 1/16 1/32 |

full half 1/4 1/8 1/16 1/32 |

full half 1/4 1/8 1/16 1/32 1/64 1/128 1/256 |

| Automatic decay selection: |  |

|

|

||

| Automatic gain control (AGC): |  |

||||

| Driver IC: | MP6500 | DRV8834 | DRV8825 | TB67S249FTG | discrete MOSFETs |

| Price (connectors not soldered): | $32.95 | $42.95 | $42.95 | $52.95 | $62.95 |

| Price (connectors soldered): | $34.95 | $44.95 | $44.95 | $54.95 | $64.95 |

1 See product pages and user’s guide for operating voltage limitations.

Introductory special

As usual, we are offering an extra introductory special discount on the Tic 36v4, to help share in our celebration of releasing a new product. The first hundred customers to use coupon code TIC36V4INTRO can get up to five units for just $24.95! And we’ll even cover the shipping in the US!

New products: more special servos with position feedback

We have expanded our selection of specially modified FEETECH servos that have direct access to the feedback potentiometer through an extra fourth (green) wire! Several months ago, we started carrying similarly modified micro FS90-FB and standard-sized FS5103B-FB servos. Now, our larger selection includes a variety of sizes from compact sub-micro servos all the way up to ultra-high torque giant servos:

- FEETECH Sub-Micro Servo FS0403-FB with Position Feedback

- FEETECH Mini Servo FT1117M-FB with Position Feedback

- FEETECH High-Torque Servo FS5115M-FB with Position Feedback

- FEETECH Ultra-High-Torque, High-Voltage Digital Giant Servo FT5335M-FB with Position Feedback

|

|

|

|

These new additions are special versions of the normal sub-micro FS0403, mini FT1117M, high-torque standard-size FS5115M, and ultra-high-torque giant FT5335M FEETECH servos.

The feedback voltage, which varies linearly over the servo’s range of motion by a couple of volts, is especially useful for more complex robotic applications that require monitoring the actual servo position. For example, it can be used for determining if the servo is stalled or when it has reached it’s target position. It also allows you to implement your own higher-level closed-loop position control or create servo movements by hand that you can record and play back later.

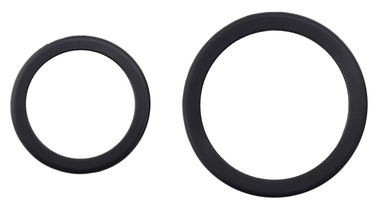

New product: more Silicone Tires for Pololu wheels!

|

Silicone Tire Pair for 40×7mm (left) and 32×7mm (right) Pololu Wheels. |

|---|

We are now offering replacement tires for our 32×7mm wheels and for our 40×7mm wheels. These are intended primarily as replacement parts for our wheels, but they can also be used as nicer tires for other similarly sized wheels.

|

|

|

Along with the tires we released last month for our larger Pololu wheels, we now have replacement tires available in four sizes that can stretch to work with six different sizes of Pololu wheels:

|

From left to right: Silicone Tire for 32×7mm, 40×7mm, 60×8mm/70×8mm, and 80×10mm/90×10mm Pololu Wheels. |

|---|

New High-Power Stepper Motor Driver 36v4

|

Pololu High-Power Stepper Motor Driver 36v4 (md38a) with large stepper motor. |

|---|

I am very excited to announce the release of our new High-Power Stepper Motor Driver 36v4, our most powerful stepper motor driver yet, with more than twice the current capabilities of any of our alternative drivers. This driver can deliver a continuous 4 A per phase without any heat sinks or active cooling, and up to 6 A with cooling! This means we finally have a driver capable of powering our largest stepper motors like this beefy motor with a 2.8 A current rating.

This new driver also has a wide 8 V to 50 V operating range, making it great for use in 12, 24, or 36 V systems. And though you might be thinking that your stepper motor’s voltage rating is well below that max voltage so what do you care, keep in mind that running you stepper motor at a higher voltage while actively limiting the current (as you can do with all our stepper motor drivers) allows you to achieve higher step rates than you could using the rated voltage.

Other exciting features of this driver include nine different step resolutions down to 256 microsteps, STALL and BEMF (back EMF) outputs that enable more advanced control algorithms, and highly adjustable decay parameters and modes for creating ultra-smooth motion profiles. The driver is configurable through its SPI interface, and our Arduino library and example sketches can help you get started.

As usual, we are offering an extra introductory special discount on the High-Power Stepper Motor Driver 36v4 to help share in our celebration of releasing a new product. The first hundred customers to use coupon code HPSMDINTRO can get up to three units for just $8.95 each!

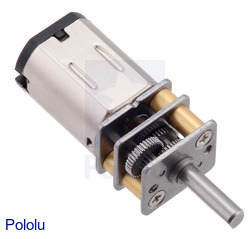

New high-gear ratio Micro Metal Gearmotors

Our Micro Metal Gearmotors are now available with 380:1 gearboxes, offering a new high gear ratio option between our existing 298:1 and 1000:1 versions. Unlike the 1000:1 gearmotors, which uniquely require a longer, more expensive gearbox to achieve such a big reduction, the 380:1 gearboxes fit everything in the same volume as all our lower gear ratios, so they are the same price as those lower-ratio versions and they work with all our micro metal gearmotor brackets.

What really sets these new units apart from our other gear ratios are their stainless steel gearbox plates, which are more durable than the ubiquitous brass ones, especially in applications with non-negligible radial loads. They also look way cooler! Continued…

New 5:1 Glideforce light-duty linear actuators

We have filled out our line of 5:1 Glideforce Light-Duty Linear Actuators to include all of Concentric’s available lengths by adding 2″, 6″, 8″, and 10″ versions, with and without feedback, to our existing 4″ and 12″ options. The low gear ratio makes these our fastest (but weakest) linear actuators, capable of lifting up to a few dozen pounds at speeds up to 1.7″ per second (44 mm/s) at 12 V. For stronger but slower options, we have versions available with a 10:1 gear ratio or 20:1 gear ratio.

This brings our total selection of light-duty actuators to 36 options:

| Actuator Type |

Max Dynamic Load |

No-Load Speed @ 12 V |

Max-Load Speed @ 12 V |

Current Draw @ 12 V |

Nominal Stroke Length |

With Feedback |

Without Feedback |

|---|---|---|---|---|---|---|---|

| Light-Duty (LD) 5:1 |

15 kgf [34 lbs] |

4.4 cm/s [1.7″/s] |

3.6 cm/s [1.4″/s] |

1.2 A – 3.2 A |

2″ | LACT2P-12V-05 | LACT2-12V-05 |

| 4″ | LACT4P-12V-05 | LACT4-12V-05 | |||||

| 6″ | LACT6P-12V-05 | LACT6-12V-05 | |||||

| 8″ | LACT8P-12V-05 | LACT8-12V-05 | |||||

| 10″ | LACT10P-12V-05 | LACT10-12V-05 | |||||

| 12″ | LACT12P-12V-05 | LACT12-12V-05 | |||||

| Light-Duty (LD) 10:1 |

25 kgf [55 lbs] |

2.8 cm/s [1.1″/s] |

2.3 cm/s [0.9″/s] |

1.2 A – 3.2 A |

2″ | LACT2P-12V-10 | LACT2-12V-10 |

| 4″ | LACT4P-12V-10 | LACT4-12V-10 | |||||

| 6″ | LACT6P-12V-10 | LACT6-12V-10 | |||||

| 8″ | LACT8P-12V-10 | LACT8-12V-10 | |||||

| 10″ | LACT10P-12V-10 | LACT10-12V-10 | |||||

| 12″ | LACT12P-12V-10 | LACT12-12V-10 | |||||

| Light-Duty (LD) 20:1 |

50 kgf [110 lbs] |

1.5 cm/s [0.57″/s] |

1.2 cm/s [0.48″/s] |

1.2 A – 3.2 A |

2″ | LACT2P-12V-20 | LACT2-12V-20 |

| 4″ | LACT4P-12V-20 | LACT4-12V-20 | |||||

| 6″ | LACT6P-12V-20 | LACT6-12V-20 | |||||

| 8″ | LACT8P-12V-20 | LACT8-12V-20 | |||||

| 10″ | LACT10P-12V-20 | LACT10-12V-20 | |||||

| 12″ | LACT12P-12V-20 | LACT12-12V-20 | |||||

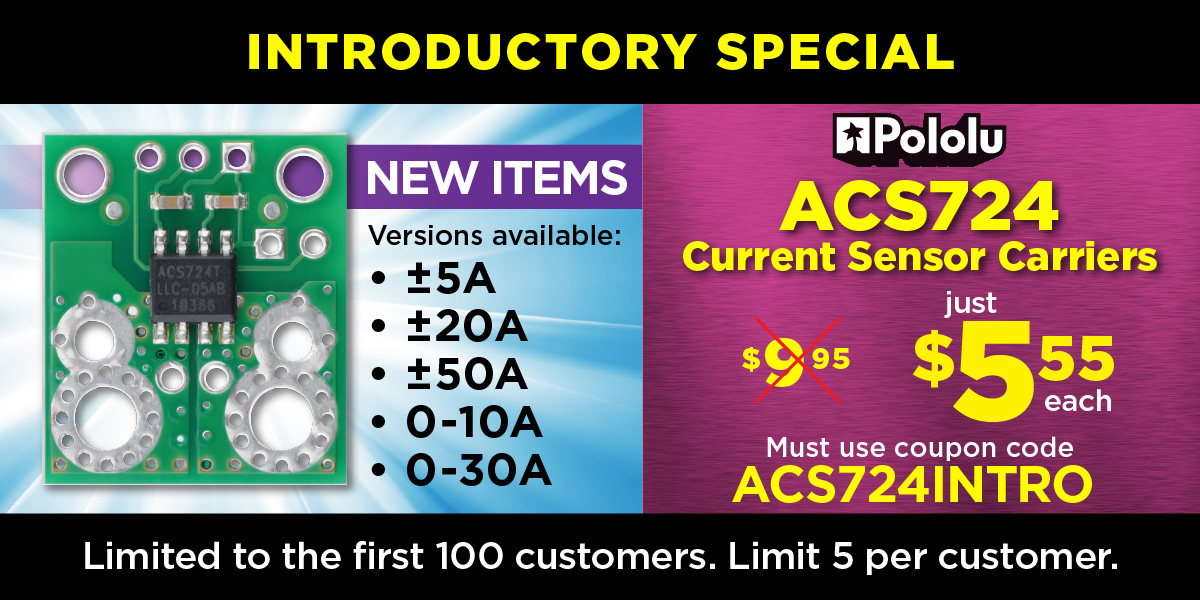

New products: ACS724 current sensor carriers

|

We now have new current sensors based on Allegro’s ACS724, the successor to the ACS714 that we have been using for many years. The ACS724 offers a number of exciting improvements over the ACS714, including more current range options (up to ±50 A!), over twice the sensitivity for the ±5 A version, a higher bandwidth for faster response times, and differential Hall sensing for substantially reduced interference from ambient magnetic fields. In quick tests, we saw a variation of around 1% of the full range just from changing the orientation of the ACS714 in space (because of the Earth’s magnetic field), while the ACS724 output stayed steady regardless of orientation. We also tried bringing a small magnet close to each sensor, and its effect on the output was many times smaller on the ACS724.

These bidirectional and unidirectional current sensors are a simple way to gain fundamental insight into the performance of your system. You can use them for closed-loop torque control of actuators, tracking power consumption over time, or even as inexpensive current probes for an oscilloscope. They output an analog voltage that varies linearly with the current passing through them, and because they use the Hall effect to measure the current, they offer full electrical isolation of the current path from the sensor’s electronics. This method of sensing means the sensor can be inserted anywhere into the current path, including on the high side, and because their current path resistance is on the order of 1 mΩ or less, they have minimal effect on the rest of the system.

Five different current ranges are available:- ACS724 Current Sensor Carrier -5A to +5A

- ACS724 Current Sensor Carrier -20A to +20A

- ACS724 Current Sensor Carrier -50A to +50A

- ACS724 Current Sensor Carrier 0A to 10A

- ACS724 Current Sensor Carrier 0A to 30A

Together with the Broadcom ACHS-712x current sensors we released last month, this brings our full current sensor lineup to thirteen sensors:

ACS709 Current Sensor Carrier |

ACS711EX Current Sensor Carriers |

ACS714 Current Sensor Carriers |

ACS724 Current Sensor Carriers |

ACHS-712x Current Sensor Carriers |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sensor IC: | ACS709 | ACS711EX | ACS714 | ACS724 | ACHS-712x | ||||||

| Current range / sensitivity(1): | ±75 A / 28 mV/A | ±15.5 A / 136 mV/A ±31 A / 68 mV/A |

±5 A / 185 mV/A ±30 A / 66 mV/A |

0–10 A / 400 mv/A 0–30 A / 133 mV/A ±5 A / 400 mV/A ±20 A / 100 mV/A ±50 A / 40 mV/A |

±10 A / 185 mV/A ±20 A / 100 mV/A ±30 A / 66 mV/A |

||||||

| Path resistance: | 1.1 mΩ | 0.6 mΩ | 1.2 mΩ | 1.2 mΩ | 0.7 mΩ | ||||||

| Bandwidth | 120 kHz | 100 kHz | 80 kHz | 120 kHz | 80 kHz | ||||||

| Vcc range:(1) | 3 V–5.5 V | 3 V–5.5 V | 4.5 V–5.5 V | 4.5 V–5.5 V | 4.5 V–5.5 V | ||||||

| Size: | 0.82″ × 0.9″ | 0.7″ × 0.8″ | 0.7″ × 0.8″ | 0.7″ × 0.8″ | 0.7″ × 0.8″ | ||||||

| Special features: | configurable over-current threshold, low-voltage operation, high bandwidth |

over-current fault pin, low-voltage operation |

Differential Hall sensing rejects common-mode fields, high bandwidth |

||||||||

| 1-piece price: | $5.95 | $4.85 | $19.95 | $9.95 | $6.95 | ||||||

| 1 Sensitivity based on when Vcc is 5V. | |||||||||||

Introductory special

As usual, we are offering an extra introductory special discount on the ACS724 current sensor carriers, to help share in our celebration of releasing a new product. The first hundred customers to use coupon code ACS724INTRO can get up to five units for just $5.55 each!

New product: Silicone Tires for Pololu wheels

|

Silicone Tire Pair for 80×10mm/90×10mm (left) and 60×8mm/70×8mm (right) Pololu Wheels. |

|---|

We have recently had several requests for just the tires from our largest Pololu wheels, so here they are! The silicone tires are available in two sizes, with the smaller tire working with our 60×8mm and 70×8mm wheels and the larger tire working with our 80×10mm and 90×10mm wheels. The tires are intended primarily as replacement parts for our wheels, but they can also be used as nicer tires for other similarly sized wheels, such as the 2-5/8″ plastic wheels for Futaba servos.

|

|

|

|

New product: DB15 Screw Terminal Adapter for MCP23X/26X Advanced Motor Controllers

|

|

We are now carrying a DB15 Screw Terminal Adapter for MCP23X/26X Advanced Motor Controllers. The adapter breaks out connections from the DB15 connector to a set of screw terminals, making accessing those pins easier during prototyping. It is designed specifically to work with the MCP Advanced Motor Controllers that feature a DB15 connector: the MCP233, MCP236, MCP263, and MCP266. However, it could also be used as a generic breakout board for other hardware that uses the same connector, like old computer joysticks or MIDI devices (where it is called a game port).