Pololu Blog » User Profile: Emily » Posts by Emily »

Posts by Emily (Page 4)

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

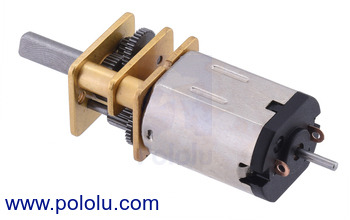

New products: micro metal gearmotors with 15:1 gear ratio

|

We have expanded our line of micro metal gearmotors to include versions with a 15:1 gear ratio. As with all of our other micro metal gearmotors, these units are available with five different motor options:

|

- Motors with precious metal brushes

- Motors with longer-life carbon brushes (HPCB)

Each motor is available with or without an extended back shaft, which rotates at the same speed as the input to the gearbox and offers a way to add an encoder, such as our encoders for micro metal gearmotors (see the picture above). This makes ten new versions in all:

| Rated Voltage |

Motor Type |

Stall Current (A) |

No-Load Current (A) |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Single-Shaft (Gearbox Only) |

Dual-Shaft (Gearbox & Motor) |

|

|---|---|---|---|---|---|---|---|---|---|

| (kg ⋅ cm) | (oz ⋅ in) | ||||||||

| 12 V | high-power, carbon brushes (HPCB) |

0.75 | 0.06 | 2200 | 0.25 | 3.5 | 1.4 | 15:1 HPCB 12V | 15:1 HPCB 12V dual-shaft |

| 6 V | high-power, carbon brushes (HPCB) |

1.5 | 0.10 | 2100 | 0.25 | 3.5 | 1.3 | 15:1 HPCB 6V | 15:1 HPCB 6V dual-shaft |

| 6 V | high-power (HP) |

1.6 | 0.07 | 2000 | 0.30 | 4.2 | 1.5 | 15:1 HP 6V | 15:1 HP 6V dual-shaft |

| 6 V | medium-power (MP) |

0.67 | 0.04 | 1400 | 0.20 | 2.8 | 0.70 | 15:1 MP 6V | 15:1 MP 6V dual-shaft |

| 6 V | low-power (LP) |

0.36 | 0.02 | 860 | 0.17 | 2.4 | 0.37 | 15:1 LP 6V | 15:1 LP 6V dual-shaft |

More detailed specifications for all our micro metal gearmotors can be found in their datasheet (5MB pdf).

These new versions bring our total micro metal gearmotor selection to 130 options, with gear ratios ranging from 5:1 to 1000:1! To see them all, visit our micro metal gearmotor category, and visit our metal gearmotor category to see all of our metal gearmotor options. Keep in mind if you don’t see an option that suits your application, for sufficient volumes, modifications such as customized output shafts are available.

Once you find the perfect gearmotors for your project, don’t forget to check out our great selection of accessories. These were all designed either specifically for our micro metal gearmotors or with their compatibility in mind:

- Wheels and tracks

- Universal mounting hubs with #2-56, #4-40, or M3 holes.

- 12mm Hex Wheel Adapter for 3mm Shaft

- Mounting brackets in white, black, or extended options

- Magnetic and optical encoders

|

|

|

Our sale has ended, but visit our specials category for great deals all year long!

|

Our Black Friday Sale has come to an end. As we ship out the last of our Cyber Monday orders, we’d like to point out our Specials category where you can find great deals on Pololu products any time of the year! For the last couple years, we’ve released most of our new products with special intro coupons. If you see a product’s intro banner listed in the specials category, its intro coupon is still active! There’s lots of great deals waiting to be used up, so make sure to have a look before you place your next order!

Design your personalized Black Friday doorbusters

26 November Update: We are no longer accepting doorbuster submissions. If you submitted wishes for doorbuster coupons, thank you! You should receive an email from us soon. All the sale details are now up on the Black Friday sale page.

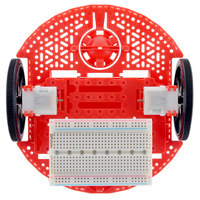

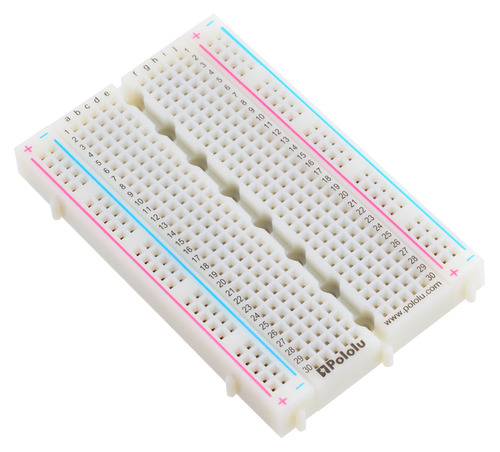

New product: Pololu 400-Point Breadboard with Mounting Holes

|

What’s this? A 400-Point breadboard with mounting holes! We know you’ve been waiting for this your whole life.

Okay, maybe not. But hey, mounting holes are awesome, and now you can pick up some of our new 400-point breadboards and mount them all over the place!

This 3.2″ × 2.1″ breadboard is fairly standard in many ways. It has four bus lines spanning the length of the board and 30 rows of pins, enough for up to four 14-pin DIP ICs or three 16-pin DIP ICs. The rows and columns of tie points are conveniently labeled, multiple units can be connected for larger projects, and it has an adhesive backing for those of you who like sticking breadboards on things.

|

|

But this breadboard is also a little special. It has eight mounting holes for M2 or #2 screws spaced evenly down the center on a 1 cm pitch. Now you can do stuff like mount your breadboard to a Romi Chassis (or any robot chassis) with some standoffs like this:

|

|

|

Wow! So convenient! And they’re just $2.49 each! But, even better, we’ve got a special discounted price for the first hundred customers. Get up to 10 boards at just $1.75 each using coupon code 400PTBBINTRO!

Polo-BOO! Halloween Sale

Looking to make an awesome Halloween costume or impressive yard display? Well, we want to help, so we’re having a sale through Wednesday, October 23 on hundreds of items you can use to make things that will impress or terrify your friends and neighbors! Visit the sale page for more information, and if you are in need of some inspiration, check out our Halloween-tagged blog posts for some sample projects.

By the way, we’d love to see more about the amazing things you all are building with our products, so please don’t hesitate to share them with us.

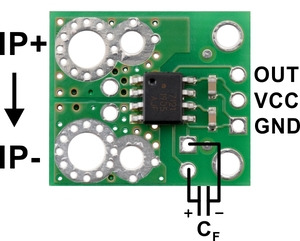

New products: ACHS-7124/7125 current sensor carriers

|

We have expanded our line of Hall effect-based linear current sensors from Broadcom to include ±40 A and ±50 A versions. These easy-to-use bidirectional current sensors are now available in five current range options:

- ACHS-7121 Current Sensor Carrier -10A to +10A

- ACHS-7122 Current Sensor Carrier -20A to +20A

- ACHS-7123 Current Sensor Carrier -30A to +30A

- ACHS-7124 Current Sensor Carrier -40A to +40A

- ACHS-7125 Current Sensor Carrier -50A to +50A

With these additions, our full line of current sensors now includes 15 options with current and sensitivity ratings ranging from ±5 A with 400 mV/A sensitivity to ±75 A with 28 mV/A sensitivity. The following table shows all of current sensor options:

ACS709 Current Sensor Carrier |

ACS711EX Current Sensor Carriers |

ACS714 Current Sensor Carriers |

ACS724 Current Sensor Carriers |

ACHS-712x Current Sensor Carriers |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sensor IC: | ACS709 | ACS711EX | ACS714 | ACS724 | ACHS-712x | ||||||

| Current range / sensitivity(1): | ±75 A / 28 mV/A | ±15.5 A / 136 mV/A ±31 A / 68 mV/A |

±5 A / 185 mV/A ±30 A / 66 mV/A |

0–10 A / 400 mv/A 0–30 A / 133 mV/A ±5 A / 400 mV/A ±20 A / 100 mV/A ±50 A / 40 mV/A |

±10 A / 185 mV/A ±20 A / 100 mV/A ±30 A / 66 mV/A ±40 A / 50 mV/A ±50 A / 40 mV/A |

||||||

| Path resistance: | 1.1 mΩ | 0.6 mΩ | 1.2 mΩ | 1.2 mΩ | 0.7 mΩ | ||||||

| Bandwidth | 120 kHz | 100 kHz | 80 kHz | 120 kHz | 80 kHz | ||||||

| Vcc range:(1) | 3 V–5.5 V | 3 V–5.5 V | 4.5 V–5.5 V | 4.5 V–5.5 V | 4.5 V–5.5 V | ||||||

| Size: | 0.82″ × 0.9″ | 0.7″ × 0.8″ | 0.7″ × 0.8″ | 0.7″ × 0.8″ | 0.7″ × 0.8″ | ||||||

| Special features: | configurable over-current threshold, low-voltage operation, high bandwidth |

over-current fault pin, low-voltage operation |

Differential Hall sensing rejects common-mode fields, high bandwidth |

||||||||

| 1-piece price: | $5.95 | $4.85 | $19.95 | $9.95 | $6.95 | ||||||

| 1 Sensitivity based on when Vcc is 5V. | |||||||||||

Introductory special

As usual, we are offering an extra introductory special discount on the ACHS-712x current sensor carriers, to help share in our celebration of releasing a new product. The first hundred customers to use coupon code ACHSINTRO can get up to five units for just $3 each!

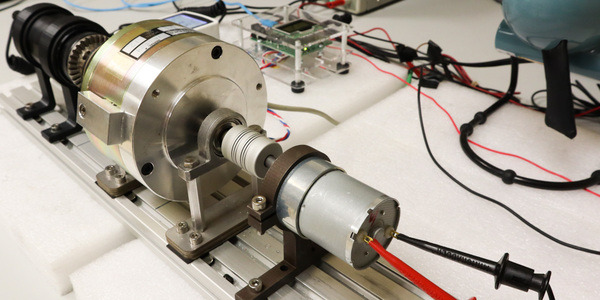

37D gearmotors: helical pinion gear, new 150:1 gear ratio, and performance graphs

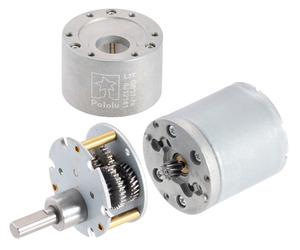

|

|

We have some big announcements related to our 37D Metal Gearmotors to share! First, we now have new versions of our 37D gearmotors that feature helical pinion gears and first mating gears as seen in the photo on the left above. The helical gears help reduce vibrations, making the gearbox a little quieter and more efficient than the original versions that used all spur gears. The performance is otherwise unchanged, and the dimensions are the same, so the new versions with helical pinion gears can be used as direct replacements for the original units. We are using new product numbers for the new versions so you can know exactly which one you are getting, and the product numbers for the original spur versions are being phased out. The following table shows all of the new helical-pinion versions:

| Rated Voltage |

Stall Current |

No-Load Current |

Gear Ratio | No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Without Encoder |

With Encoder |

|

|---|---|---|---|---|---|---|---|---|---|

| (kg ⋅ cm) | (oz ⋅ in) | ||||||||

| 12 V | 5.5 A | 0.15 A | 1:1 (no gearbox) | 10,000 | 0.5 | 7 | – | – | item #4750 |

| 19:1 | 540 | 8.5 | 120 | 12 | item #4741 | item #4751 | |||

| 30:1 | 330 | 14 | 190 | 12 | item #4742 | item #4752 | |||

| 50:1 | 200 | 21 | 290 | 10 | item #4743 | item #4753 | |||

| 70:1 | 150 | 27 | 380 | 10 | item #4744 | item #4754 | |||

| 100:1 | 100 | 34 | 470 | 8 | item #4745 | item #4755 | |||

| 131:1 | 76 | 45 | 630 | 6 | item #4746 | item #4756 | |||

| 150:1 | 67 | 49 | 680 | 6 | item #2829 | item #2828 | |||

We have also expanded the 37D gearmotor line by adding a new 150:1 gear ratio, which becomes our new highest gear ratio offering for this line of gearmotors. This version has an extrapolated (i.e. theoretical) stall torque of 49 kg⋅cm (680 oz⋅in), but please keep in mind that the point of high gear ratios like this is not to allow for more total torque. Rather, they enable slower speeds and draw less current than lower gear ratios for the same loads. For all of our 37D gearmotors, we recommend keeping continuously applied loads under 10 kg⋅cm (150 oz⋅in) and instantaneous torques under 25 kg⋅cm (350 oz⋅in).

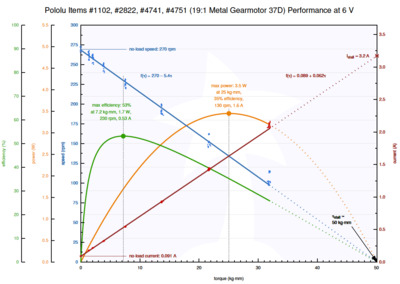

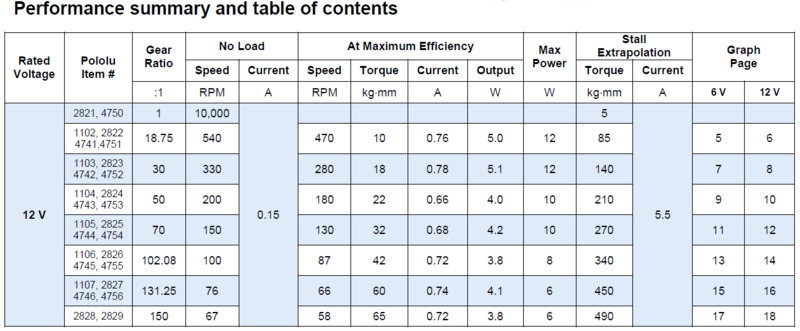

Finally, we now have published performance graphs (1MB pdf) for our 37D gearmotors, just like the ones we previously released for our Micro Metal Gearmotors and our 20D Gearmotors! Each chart is based on hundreds of individual measurements that reveal how the speed, current, power, and efficiency of that particular gearmotor version depend on the applied load (i.e. torque).

|

37D mm metal gearmotor undergoing dynamic performance testing. |

|---|

These characterizations are yet another way we set our gearmotors apart from the many similar-looking alternatives out there. When you get your gearmotors from us, you know exactly what kind of performance to expect, and because we make and test them ourselves, you can count on getting that same performance batch after batch after batch.

If you have any questions or feedback about these graphs or if there is additional information you would like to see available for our motors, please feel free to contact us (or just leave a comment below). And if you are wondering about graphs for 25D Gearmotors, don’t worry, those are coming! (If you need something before those datasheets are done, just let us know and we might be able to get you preliminary data for a particular gearmotor.)

|

Performance summary table from 37D mm Metal Geamotor datasheet. |

|---|

Labor Day Sale 2019

We are having a Labor Day sale through Tuesday, September 3! Check out the sale page for more information. Please note that we will be closed Monday, September 2, so orders placed after 2 PM Pacific Time Friday, August 30th will be shipped on Tuesday, September 3.

Ham radio antenna rotor control using a Tic Stepper Motor Controller

Pablo Lewin wanted a way to adjust the antenna for his Ham radio remotely, but was told his antenna controller was too old to upgrade for remote operation. That didn’t deter him though! He got creative and came up with a solution by connecting a stepper motor to his antenna controller and then using one of our Tic Stepper Motor Controllers. Now he can access the computer the Tic is connected to remotely and control the antenna’s position through the Tic’s software. Check out the video below to see his setup:

Here’s the video Pablo recommends at the beginning of his explanation to get up and running with your own Tic Stepper Motor Controller:

Independence Day Sale 2019

We are having an Independence Day sale from now through Monday, July 8! Check out the sale page for more information. Please note that we will be closed Thursday, July 4, so orders placed after 2 PM Pacific Time Wednesday, July 3 will be shipped on Friday, July 5.