Pololu Blog » Posts tagged “new products” »

Posts tagged “new products” (Page 19)

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

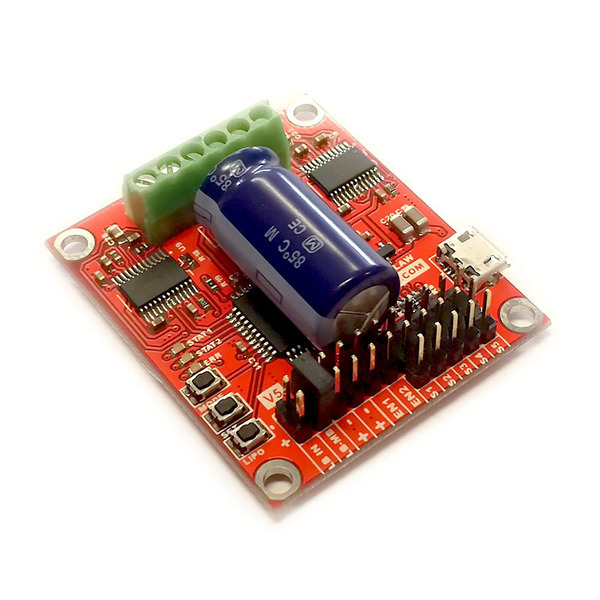

New product: Ion Motion Control RoboClaw 2x7A dual motor controller (V5)

|

The RoboClaw motor controllers from Ion Motion Control (formerly Orion Robotics) can control a pair of brushed DC motors using USB serial, TTL serial, RC, or analog inputs. Integrated dual quadrature decoders make it easy to create a closed-loop speed control system.

Ion Motion Control has replaced the MOSFETS on the RoboClaw 2x5A Motor Controller (V5) with better ones and is now calling it the RoboClaw 2x7A Motor Controller (V5). The 2x7A can supply up to 7.5 A continuous and 15 A peak, up from 5 A and 10 A, and is otherwise functionally and physically identical to the 2x5A.

More details are on the RoboClaw 2x7A Motor Controller (V5) product page.

New Pololu Zumo T-Shirts

|

Robot enthusiasts: if you want to show your Pololu pride but covering yourself with Pololu stickers just doesn’t seem fashionable, we’ve got good news for you! Our new Zumo T-shirts are here, featuring a Zumo 32U4 robot within a sprocket-inspired border, accompanied by our call to “Engage Your Brain”. These pre-shrunk cotton shirts are available in several colors (royal blue, cardinal red, or charcoal gray) and a range of sizes.

|

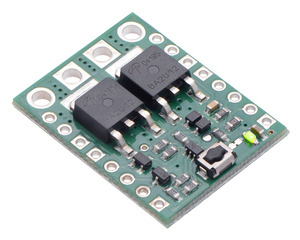

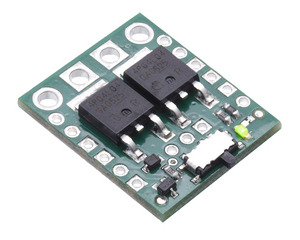

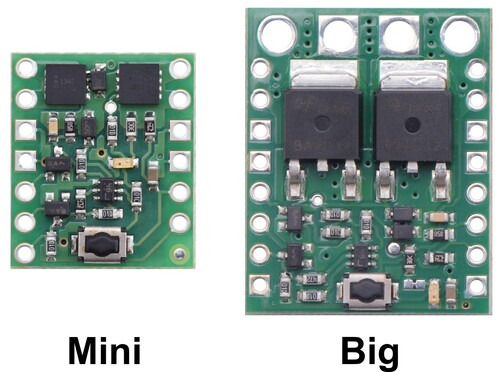

New big MOSFET-based power switches

Our mini MOSFET-based power switches now have a set of companion versions with larger MOSFETs:

|

As I mentioned when announcing the Mini switches in September, they have many advantages over our older pushbutton power switches, including a much larger input voltage range and reverse protection, but the current limits were lower. With the new big switches, we can now support applications well beyond what the older products could handle. We are offering two versions with different MOSFETS: the MP unit can handle about 8 A, and the HP version is good for about 16 A. Both operate over the same 4.5 V to 32 V range as the Mini SV switches.

Like the mini power switches, these big switches are available with our patented push-on/push-off latching circuit or with a simple slide switch:

|

|

For more information, see the links below or check out our power switch category.

New products: Scooter/Skate Wheels

We are rolling out another set of new products here at Pololu: Scooter/Skate Wheels. They are available in 144×29 mm, 100×24 mm, 84×24 mm, and 70×25 mm sizes, offering larger alternatives to our line of Pololu Wheels. They are compatible with standard 608 bearings, so they also work with our Aluminum Scooter Wheel Adapters, which make it easy to connect these wheels directly to an assortment of motors for use in robot drive systems:

|

|

You can find more information about these wheels on their product pages:

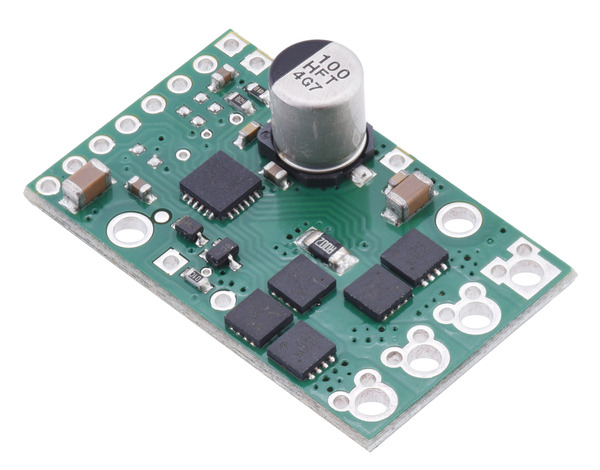

New product: G2 High-Power Motor Driver 24v13

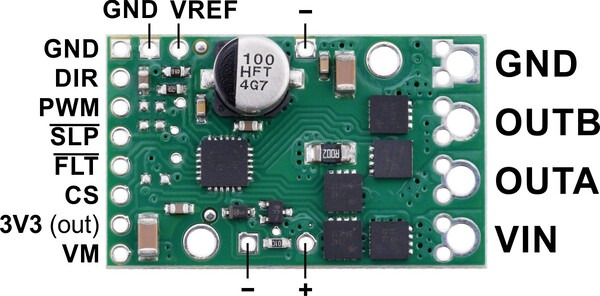

We are excited to announce the release of the Pololu G2 High-Power Motor Driver 24v13. Like our original high-power motor drivers, this board is a discrete MOSFET H-bridge that is designed to drive large DC brushed motors. As the first of our second-generation high-power motor drivers, the 24v13 can supply a motor with a continuous current as high as 13 A at voltages between 6.5 V and 40 V (absolute maximum).

|

The G2 driver is designed to be a near drop-in replacement for its predecessor, with an identical form factor and a similar pinout, but it offers a number of new features and improvements over the older version. Reverse-voltage protection on the power supply inputs helps prevent instant destruction if a battery is connected backwards, while basic current sensing and limiting functionality help the driver handle large loads more gracefully. The G2 driver is also compatible with systems running at 3.3 V (and lower), unlike our original high-power motor drivers.

To learn more about the motor driver’s features and capabilities, see its product page.

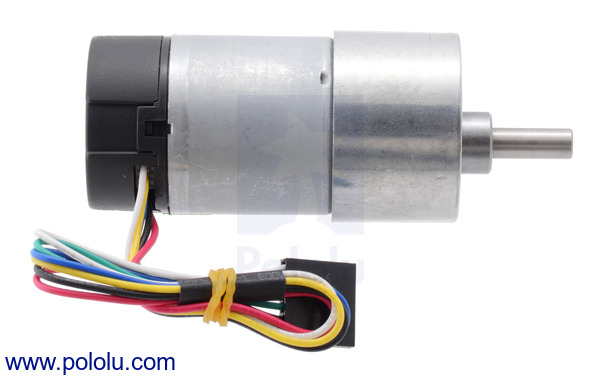

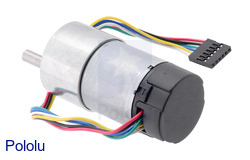

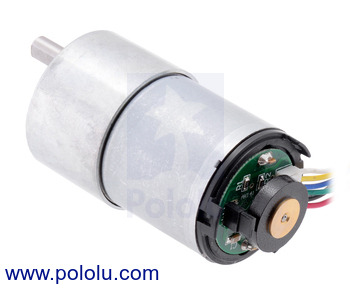

37D mm metal gearmotors with encoders and end caps

Our 37D mm metal gearmotors now have fitted plastic end caps over their encoders that neatly protect the assembly and keep stray objects clear of the magnetic disc. The pictures below show the previous version (without end cap) next to one of the new ones:

|

|

The end cap is easily removable if you need to access the encoder or want a few more millimeters of clearance for your gearmotor, but there is a little bit of base plastic that will remain (as shown in the picture below), so removing the end cap does not quite make these new ones identical to the previous versions.

|

37D mm metal gearmotor with 64 CPR encoder (with end cap removed). |

|---|

These gearmotors are available in six different gear ratios and with or without encoders, and we also carry the motor and encoder assembly by itself with no gearbox. The following table shows all of our 37D mm metal gearmotor options:

| Gear Ratio | No-Load Speed @ 12 V |

Stall Torque @ 12 V |

Stall Current @ 12 V |

With Encoder |

Without Encoder |

|---|---|---|---|---|---|

| 1:1 | 11,000 RPM | 5 oz-in | 5 A | motor without gearbox | |

| 19:1 | 500 RPM | 84 oz-in | 5 A | 37Dx52L mm | 37Dx52L mm |

| 30:1 | 350 RPM | 110 oz-in | 5 A | 37Dx52L mm | 37Dx52L mm |

| 50:1 | 200 RPM | 170 oz-in | 5 A | 37Dx54L mm | 37Dx54L mm |

| 70:1 | 150 RPM | 200 oz-in | 5 A | 37Dx54L mm | 37Dx54L mm |

| 100:1 | 100 RPM | 220 oz-in | 5 A | 37Dx57L mm | 37Dx57L mm |

| 131:1 | 80 RPM | 250 oz-in | 5 A | 37Dx57L mm | 37Dx57L mm |

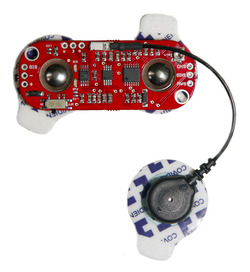

New product: MyoWare muscle sensor and electrodes

|

We are pumped to announce that we are now carrying Advancer Technologies’ MyoWare Muscle Sensor!

This sensor features a number of improvements over the older Muscle Sensor v3 including single-supply operation (no need for a negative voltage supply) and built-in snap connectors for electrodes. Other new features include a raw EMG output, reverse power protection, a power switch, LED indicators, and two mounting holes.

|

|

For a fun example that shows how you could use the muscle sensor, take a look at this blog post, which uses one of our Maestros to monitor a bicep while it is flexing, and command a servo to imitate the motion with a tiny cardstock version of He-Man’s arm. (Note that the project uses the older Muscle Sensor v3, not this new product.) You can also head on over to Advancer Technologies’ website for more project ideas.

|

|

The MyoWare Muscle Sensor does not ship with electrodes; they are available separately in packs of six.

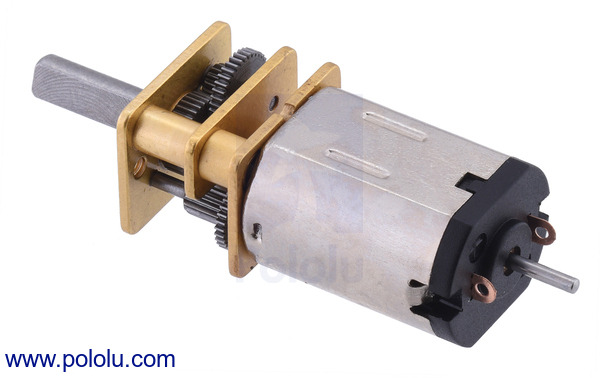

HPCB micro metal gearmotors with extended motor shafts

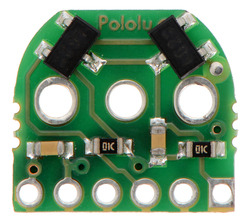

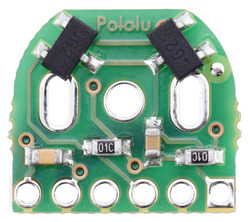

It has been a few months since we introduced our new high-power micro metal gearmotors with longer life carbon brushes. We now have them available with dual shafts, and we have made a corresponding update to our magnetic encoders to let them work with the larger terminals of the HPCB motors.

|

|

|

You might see similar-looking motors elsewhere, but no one comes close to our offering, from the quality of the gears to the variety of winding options to the selection of gear ratios, all in stock for shipment the day you order. By bringing together Pololu’s exclusive features of high-power windings, long-life carbon brushes, and encoders for closed-loop feedback control into a single package, these latest motors and encoders really demonstrate our continual investment in this popular form factor. With ten gear ratios available, from 10:1 through 1000:1, our total selection of micro metal gearmotors has grown to nearly 70 options:

| Motor Type | Stall Current @ 6 V |

No-Load Speed @ 6 V |

Approximate Stall Torque @ 6 V |

Single-Shaft (Gearbox Only) |

Dual-Shaft (Gearbox & Motor) |

|---|---|---|---|---|---|

| high-power, carbon brushes (HPCB) |

1600 mA | 3000 RPM | 4 oz-in | 10:1 HPCB | 10:1 HPCB dual-shaft |

| 1000 RPM | 9 oz-in | 30:1 HPCB | 30:1 HPCB dual-shaft | ||

| 625 RPM | 15 oz-in | 50:1 HPCB | 50:1 HPCB dual-shaft | ||

| 400 RPM | 22 oz-in | 75:1 HPCB | 75:1 HPCB dual-shaft | ||

| 320 RPM | 30 oz-in | 100:1 HPCB | 100:1 HPCB dual-shaft | ||

| 200 RPM | 40 oz-in | 150:1 HPCB | 150:1 HPCB dual-shaft | ||

| 140 RPM | 50 oz-in | 210:1 HPCB | 210:1 HPCB dual-shaft | ||

| 120 RPM | 60 oz-in | 250:1 HPCB | 250:1 HPCB dual-shaft | ||

| 100 RPM | 70 oz-in | 298:1 HPCB | 298:1 HPCB dual-shaft | ||

| 32 RPM | 125 oz-in | 1000:1 HPCB | 1000:1 HPCB dual-shaft | ||

| high-power (HP) (same specs as HPCB above) |

1600 mA | 6000 RPM | 2 oz-in | 5:1 HP | |

| 3000 RPM | 4 oz-in | 10:1 HP | 10:1 HP dual-shaft | ||

| 1000 RPM | 9 oz-in | 30:1 HP | 30:1 HP dual-shaft | ||

| 625 RPM | 15 oz-in | 50:1 HP | 50:1 HP dual-shaft | ||

| 400 RPM | 22 oz-in | 75:1 HP | 75:1 HP dual-shaft | ||

| 320 RPM | 30 oz-in | 100:1 HP | 100:1 HP dual-shaft | ||

| 200 RPM | 40 oz-in | 150:1 HP | 150:1 HP dual-shaft | ||

| 140 RPM | 50 oz-in | 210:1 HP | |||

| 120 RPM | 60 oz-in | 250:1 HP | |||

| 100 RPM | 70 oz-in | 298:1 HP | 298:1 HP dual-shaft | ||

| 32 RPM | 125 oz-in | 1000:1 HP | 1000:1 HP dual-shaft | ||

| medium-power (MP) |

700 mA | 2200 RPM | 3 oz-in | 10:1 MP | 10:1 MP dual-shaft |

| 730 RPM | 8 oz-in | 30:1 MP | |||

| 420 RPM | 13 oz-in | 50:1 MP | |||

| 290 RPM | 17 oz-in | 75:1 MP | 75:1 MP dual-shaft | ||

| 220 RPM | 19 oz-in | 100:1 MP | 100:1 MP dual-shaft | ||

| 150 RPM | 24 oz-in | 150:1 MP | |||

| 75 RPM | 46 oz-in | 298:1 MP | |||

| 25 RPM | 80 oz-in | 1000:1 MP | 1000:1 MP dual-shaft | ||

| low-power | 360 mA | 2500 RPM | 1 oz-in | 5:1 | |

| 1300 RPM | 2 oz-in | 10:1 | |||

| 440 RPM | 4 oz-in | 30:1 | 30:1 dual-shaft | ||

| 250 RPM | 7 oz-in | 50:1 | 50:1 dual-shaft | ||

| 170 RPM | 9 oz-in | 75:1 | |||

| 120 RPM | 12 oz-in | 100:1 | 100:1 dual-shaft | ||

| 85 RPM | 17 oz-in | 150:1 | |||

| 60 RPM | 27 oz-in | 210:1 | |||

| 50 RPM | 32 oz-in | 250:1 | |||

| 45 RPM | 40 oz-in | 298:1 | 298:1 dual-shaft | ||

| 14 RPM | 70 oz-in | 1000:1 | 1000:1 dual-shaft |

You can see all ten of the new versions below, and if there are any versions we do not yet have that you would like to see us carry, let us know in the comments!

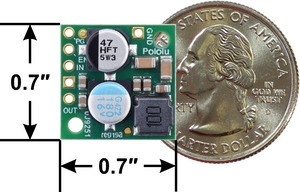

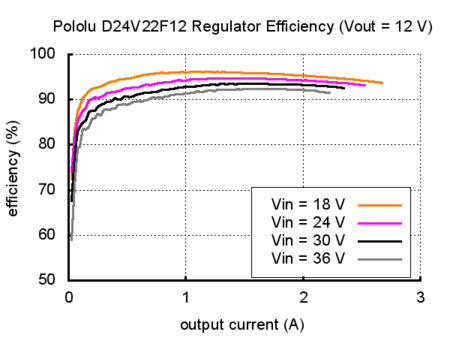

New product: 12V, 2.2A Step-Down Voltage Regulator D24V22F12

We are pleased to introduce our new 12 V, 2.2 A switching regulator, the inaugural member of the D24V22Fx family of step down voltage regulators. We expect to release other voltage versions next month, but we wanted to get a 12 V version out right away since we did not offer a 12 V buck regulator that could do more than 1 A. The compact regulator works with input voltages up to 36 V and can typically deliver up to a continuous 2.2 A. It offers integrated reverse voltage protection along with over-current and over-temperature shutoff, and a power-good output can be used to determine when the regulator cannot maintain its output voltage.

|

|

|

Unlike linear regulators which waste a lot of power and generate a lot of heat in the process, this new regulator is very efficient, which means you can get the most out of your battery life:

|

Until we release other voltage versions of the D24V22Fx, the closest substitutes are the similar D24V25Fx family of step-down voltage regulators:

These regulators are the same size as the D24V22F12 and they have similar current capabilities and input voltage ranges, but they do not have the same pinout and they are based on a different internal design, so there are fundamental differences in operation.

See the D24V22F12 product page for more information on this new regulator, or visit our voltage regulator category to see all of our regulator options.

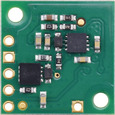

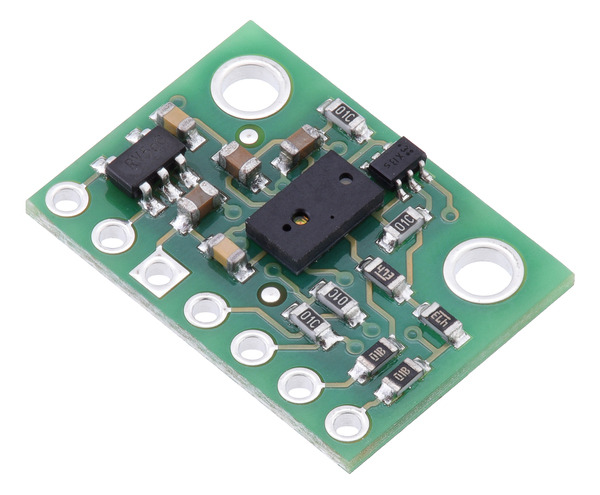

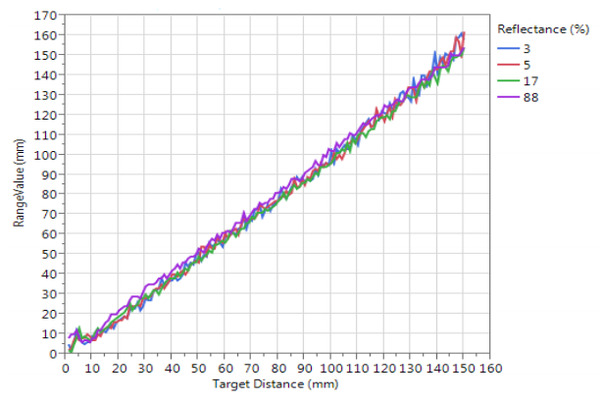

New product: VL6180X Time-of-Flight Distance Sensor Carrier

There’s another new product coming out of the assembly line here at Pololu: the VL6180X Time-of-Flight Distance Sensor Carrier. The VL6180 from ST Microelectronics distinguishes itself from other optical sensors by using time-of-flight measurements to determine distance: it emits pulses of infrared laser light and precisely times how long they take to reach the nearest object and reflect back to the sensor, which means it is essentially a complete short-range lidar system in a single tiny package.

With this technique, the VL6180X can accurately measure the absolute distance to a target object from 0 cm to at least 10 cm away – sometimes up to 20 cm away, depending on the target and environment – without being affected by what color the target is or how reflective it is.

|

VL6180X datasheet graph of typical ranging performance. |

|---|

Distance readings can be obtained through the sensor’s I²C interface (in units of millimeters – no complicated conversions necessary!). The VL6180X also includes an ambient light sensor; this combination of sensing capabilities is useful for applications, including smartphones, for which the VL6180 was designed.

|

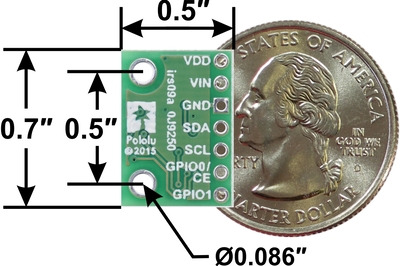

The VL6180X IC by itself is a challenge to use because of its small surface-mount package and particular voltage requirements, so our breakout board includes a 2.8 V regulator and level shifters that allow it to be used with 3.3 V and 5 V systems. The carrier board provides a breadboard-friendly pinout and mounting holes while remaining as compact as possible (0.5″ × 0.7″). We’ve also written an Arduino library for the VL6180X that makes it easy to get started with this board.

For more information about the VL6180X carrier, see its product page.