Pololu Blog » Engage Your Brain »

Engage Your Brain (Page 3)

A blog by Pololu president Jan Malášek.

COVID-19 impact update: still hanging on after three weeks

Monday, 13 April 2020 update – we got our PPP loan!

|

After 3 weeks of emergency operations, we are still shipping all orders!

Today, April 6, marks the beginning of our fourth week of emergency operations. We are still hanging on, and it looks like we will be able to maintain operations similar to those of the past three weeks (i.e. continue shipping all orders with a minimal staff on site) at least through the end of April, by which point I hope some of the emergency loans we have applied for might start coming in.

Today I am just posting some quick updates about frequently asked questions; please see my last two posts for more information about how we are coping with the coronavirus emergency:

- 22 March 2020 – initial COVID-19 impact update and appeal for donations after the first week of emergency operations, when I thought complete shutdown of Pololu operations was imminent.

- 29 March 2020 – update after two weeks, with a few sections:

- We are still operating, with every order shipped! – with tips on how to check stock and look for similar products on our site

- Thank you to everyone who has donated – with extra details about how donations help beyond immediate dollar value

- Landlord/building situation – detailed explanation about how we ended up in the building we are in and why we cannot expect any immediate help from the landlord

- SBA loans/stimulus package – some thoughts on emergency loans we are applying for (a little more info in today’s post)

- Outlook and plan for now – generally still applicable a week later

- How you can help

- 6 April 2020 – this post

- Thank you for your continued donations

- Please help reduce overwhelming workload

- Emergency loan updates

- Employee update

- Pictures of life at Pololu

- How you can help (mostly repeated from last week’s post)

Thank you for your continued donations 🙏

We are very grateful for the many donations that continue to come in. As we trim our expenses, those donations become a larger fraction of what we need to get by. I know it’s asking so much for donations with no strings attached, and it means a great deal at a time when we are scrambling to make ends meet. To the many of you making us special proposals and suggestions, thank you and please keep them coming. We do not have the resources now to reply to them individually, but they do affect what we are considering offering and how we continue to operate.

If you can, please consider donating to help Pololu make it. We have set up item 2400 for donating in $1 increments.

Please help reduce overwhelming workload (for those of us who can work)

We are especially grateful for any routine orders that do not require special considerations. We are also happy to help with emergency orders involving efforts to fight the pandemic. For smaller, non-emergency inquiries, please understand that we are trying to maintain most of our usual operations with a much more limited staff while having to take on a lot of extra work (new HR issues for navigating layoffs vs. waiting for possible stimulus funds, coming up with new operating/safety procedures, rerouting incoming and outgoing packages among constantly changing rules for each country and carrier, etc.). Please help us reduce our workload by cutting back on non-critical inquiries. For regular orders, prices and stock are all on the web site. Tracking numbers are included in shipment confirmation emails. Invoices are available on the website when you log in. For technical support, please consider our forum.

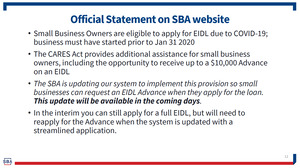

Emergency loan updates

|

One of the most common questions or recommendations we get is about applying for emergency loans. We applied for an SBA economic injury disaster loan (EIDL) almost two weeks ago and followed up with the $10k advance application provided by the new CARES Act. We have been working with our bank all weekend to apply for the new Paycheck Protection Program loan, the applications for which have just started becoming available. My understanding is that the SBA is also scrambling as it is suddenly charged with processing more than 10x what they usually do over the whole year over the next several weeks. We received some confirmation about the EIDL loan being received but there’s been no visible progress on that, and in general, it’s difficult to know what to expect in terms of if, when, and how much we might be able to receive in emergency loans.

Given that uncertainty, it is especially urgent for us to cut costs where we can and to bring in whatever money we can to keep covering basic expenses. We are definitely hoping we qualify for some assistance and that it will come soon, so we are doing everything we can to keep all those applications moving forward while also trying to maintain operations independent of any guarantee of anything coming from that.

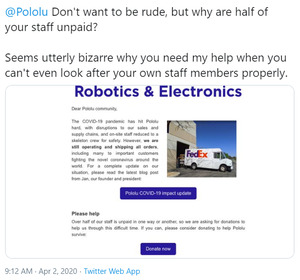

Employee update

|

We received a few responses questioning our treatment of employees while asking for donations. They are far outnumbered by positive responses, and I suspect the negative responses come from people who have little appreciation of the realities of running a small business, especially amid this level of disruption. Nevertheless, I believe more people might be wondering about what we are doing, and I am proud of our response given the circumstances, so I would like to highlight what we have done so far.

Some of the responses questioned the “over half of our staff is unpaid in one way or another” phrasing. We had about 75 employees at the beginning of March, and over half of them are now either laid off, on unpaid leave, or volunteering to take a pay cut. This is just a basic reality of payroll being by far our biggest expense, and if people cannot come in to work and money stops coming in, there is nothing to pay them from. We are doing everything we can to keep Pololu in a viable state so that there is something for everyone to come back to in a few weeks or months.

Here is some of the rest of our response:

- Prior to any Nevada mandates, we began staggering our workbenches, improving sanitizing procedures, and set up some employees for working remotely.

- Within the first day of the Nevada governor’s emergency business closure declaration, we set up an emergency forum for all employees to be able to communicate without being on site. I have been posting there almost daily to keep everyone in the loop on our operations and outlook.

- We contacted all employees to make sure we had their contact information and understood their preferences about working (different people have different preferences based on their living arrangements, risk factors for COVID-19, etc.).

- We are maintaining health insurance and similar benefits for everyone who had them, including paying the employees’ portion for those who could not work and were out of paid time off (PTO). Some employees who were scheduled to begin getting coverage through Pololu are still getting added to our plans.

- We paid out remaining PTO to those laid off.

- We are maintaining PTO for those on unpaid leave and those still working.

- We paid full amounts due to those still able to work (excluding those volunteering for pay cuts).

- We are continuing safety assessments for on-site operations, including providing face masks for all on-site staff.

- We are working on improving remote connection and work capability.

Pictures of life at Pololu

|

Pololu laser cutting department on 6 April 2020. |

|---|

|

Pololu laser cutting department on 6 April 2020. |

|---|

|

Pololu packaging department on 6 April 2020. |

|---|

|

Pololu quality control on 6 April 2020. |

|---|

|

Pololu shipping department on 6 April 2020. |

|---|

|

Pololu SMT pick and place production line on 6 April 2020. |

|---|

|

Soldering at Pololu on 6 April 2020. |

|---|

|

Pololu testing department on 6 April 2020. |

|---|

How you can help

Make a donation

If you can, please consider donating to help Pololu make it. We have set up item 2400 for donating in $1 increments.

Pay now, ship later

We have added a feature to our online checkout system to allow for orders to be placed with a “pay now, ship later” option that lets you authorize us to charge the payment for an order as soon as it comes in, possibly well ahead of when the order would actually ship. We started working on this feature at a time when we thought complete shutdown of our operations was imminent, when it might have been weeks or even months before we could reopen. As I wrote at the top of this update, we have been able to ship all orders, and I expect to continue shipping, but this option still allows us to prioritize shipments and reduce stress with orders that come in later in the day and can get shipped the next day. We have already received dozens of orders with this option selected, and it is also encouraging just to see that our customers are trying to help us out. Thank you to all of you who have selected that option!

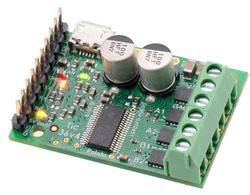

Order non-soldered versions of products, or the higher-stock versions

We offer a few of our products with some of the optional (but usually used) through-hole connectors soldered in. If you are able to solder, please consider ordering the non-soldered versions if there is plentiful stock of them. We do all of the through-hole soldering by hand, and most of our manual assemblers were older or otherwise in the higher-risk population for COVID-19, so they are not currently working here. And if you’re at home doing a non-critical project, now is a good time to do a little extra soldering, right?

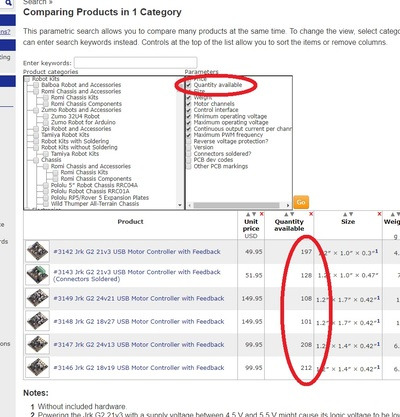

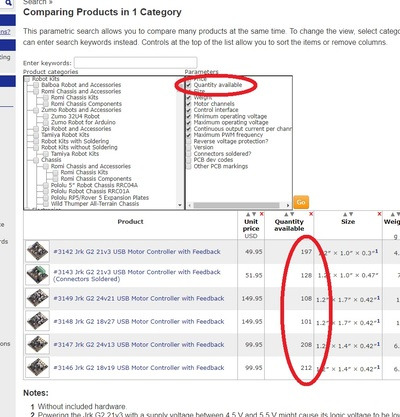

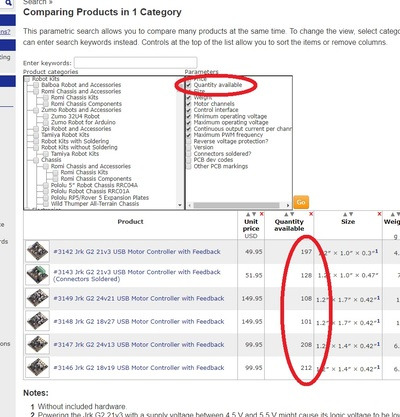

On a related note, it’s a little bit easier for us if you order the item that has more stock. Each product page has links to relevant parametric comparison tables that can help you identify similar products that might have more available stock:

|

You can check available quantity of similar products on the parametric comparison table. |

|---|

If your application could get by with either an item of which we have 300 in stock or one of which we have 12 units, please get the product that we have much more of. It’s probably a more popular version that we make more often, and it keeps the less popular version available for those who might really need it.

Help each other on our forum

We have had to severely cut back on our technical support. If you are one those people with extra time on your hands now and are familiar with any of our products, please consider helping out our other customers on our forum.

Ask others to help us out

If you know anybody that could afford to help us out, please let them know and ask them to contribute.

Other suggestions and ideas

Part of the reason I have been going into more details in some areas of these updates is so you might be able to better give us advice about how we could make things better. Maybe you’re also working at a small business facing similar challenges, and you have some good suggestions. Maybe your uncle has a vacant building nearby. One suggestion I’ve heard repeatedly is about gift certificates, which we are looking into; if you know of particularly good ways of implementing that or things to be careful about, please let us know.

Thank you all for your support. Stay safe and healthy, everybody!

Monday, 13 April 2020 update – we got our PPP loan!

Coronavirus impact update: still shipping all orders

Quick summary: Pololu has filled all orders and continues to operate, including shipping products to important customers fighting COVID-19 around the world. Thank you for all of your help and donations, which are really making a difference. We are preparing for extended operations under emergency conditions and evaluating all available avenues for support. Cash donations remain the most useful and immediate way to help, but there are other ways you can help us. Donate here.

Please see new update posted Monday, 6 April 2020.

|

Still shipping, 30 March 2020. |

|---|

It has been a week since I posted about Pololu’s dire circumstances brought about by the new coronavirus pandemic. My outlook today is much more positive than it was back then, in large part thanks to the support we have received during the past week. We are by no means out of the woods yet, as a company, as a country, and as a planet. I write today’s post to provide an update on how we are doing, to try to address the questions I am getting repeated from many people, to share our general outlook for moving forward, and to renew my appeal for help in any way possible. Since there are many topics that might be of varying degrees of interest to each of you, I will try to organize this with more sections and headings:

- We are still operating, with every order shipped!

- Thank you to everyone who has donated

- Updates about common questions

- Outlook and plan for now

- How you can help

We are still operating and have shipped every order!

We have operated for eight business days now with a skeleton crew of approximately 20 staff members on site and 10-20 more people assisting via remote connections from home. We have shipped every order for in-stock items that has been placed during that time, and we have limited production capacity for special orders beyond what is in stock.

We have had no new local business shutdown orders that would affect us since Friday the 20th, and we have received dozens if not hundreds of customer requests and certifications from customers that have been declared essential businesses or services within their jurisdictions, and as suppliers to those organizations, we are essential by extension as well. We also continue to get many confirmations of our products and services (e.g. laser cutting) being used directly in the response to the COVID-19 pandemic, so we will keep shipping orders as long as delivery services keep operating.

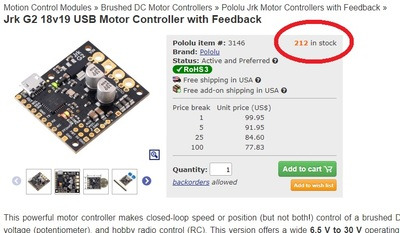

You can see available stock for each product live on our website, and if your order consists of just in-stock items, we should be able to ship your order within a day.

|

Available stock is shown on each product page. |

|---|

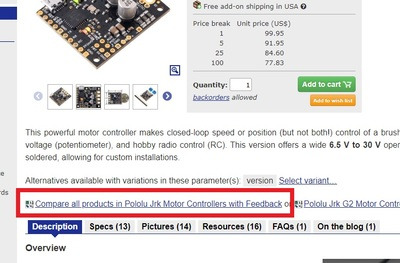

Each product page has links to relevant parametric comparison tables that can help you identify similar products that might have more available stock:

|

Each product page has links to relevant parametric comparison tables. |

|---|

|

You can check available quantity of similar products on the parametric comparison table. |

|---|

Our China facility in Shenzhen is also partially operational, and we are able to ship some special volume orders directly from there. The available shipping carriers and destinations are changing day by day as countries respond to the pandemic, but we are working with customers to route critical orders as quickly as possible. Please note that all of our electronics products are manufactured at our Las Vegas, Nevada, USA facility, so shipments directly from China are only available for select products, mostly motors and other mechanical components that we have machined or injection molded there.

We also have hundreds of distributors around the world that might be operational and have stock closer to you. We will be working with them in the coming days to update the distributors page with information about those businesses confirmed to still be in operation.

Thank you to everyone who has donated!

We have received thousands of dollars in donations since my original post. I have tried to send at least a few personal thank you emails every day, but there have been more donations than I can keep up with. It is extremely motivating to see the breadth of donations we are receiving from all over the world, from customers we haven’t heard from in a long time, to family members of employees, to former employees, to people that, as far as we can tell, have had no previous association with Pololu. To all of you whom I have not thanked yet individually, thank you!!! I am making sure everyone at Pololu knows about your support. The value of the money we receive in donations is multiplied both by the psychological boost it gives us and by getting factored into various lines of credit that we have available to us that are automatically calculated based on the rolling average revenue appearing in our accounts.

Several Pololu employees who are part of our continuing operations have volunteered reductions in their own pay so that we might conserve our limited cash on hand and continue payments and insurance for those employees that are most in need. PT from Adafruit also responded to my call for help and gave me some useful perspective and helped spread the word about our situation even as Adafruit conducted its own emergency operations out of New York, the US epicenter of the coronavirus outbreak.

The donations and support are all the more meaningful at a time like this, where nearly everyone is impacted and the future so uncertain.

If you can, please consider donating to help Pololu make it through this difficult time. You can use item 2400 to donate in $1 increments. I will also post other ways you can help us at the end of this update.

Updates about common questions

Landlord and building situation

After payroll, the building rent is our biggest expense and obligation, so I of course reached out to my landlord right away to see what their position was. Unfortunately, the building we are in was just sold in the last 6 months, so we do not have the long working history we had with the previous landlord. I am posting a little more detail here than I would normally be comfortable with, but we are in an extraordinary emergency and I am hearing the same questions and suggestions from multiple people, so I want to share this information because I believe it could be useful in getting us help and advice.

|

We are the only tenant in a building that is approximately 86,000 square feet. The building had been vacant, I think for years, after the previous economic downturn, and we moved in here at the end of 2011, taking part of the first floor. In 2013, the landlord received an offer for the second floor. It was a time when we were growing rapidly, and the building was not at all well set up for sharing with multiple tenants, so we made the owner an offer for the space and reached an agreement that was expensive but affordable for us and at a lower rate for the landlord than the competing offer but without the need to do any new construction. Over the next several years, we agreed to extensions in the lease and a gradual takeover of the remainder of the first floor, so that we would officially have the building to ourselves and the landlord could stop looking for other tenants to fill the remaining space.

In 2018, we negotiated a new extension of the lease. The building was still in its as-is state from 2009 or whenever the previous tenants moved out, and it was a particularly impractical floorplan based on the previous tenant’s operations. The landlord preferred putting some money into renovating the space and increasing our rent over keeping the rent at a bare minimum, and so even though our cost went up again, we were getting a more usable space with plenty of room for growth at still a decent total cost. The renovations took longer than expected and ran through most of 2019. Some kind of family change caused the landlord to unexpectedly have to sell the building, which got us to where we are today: with a new owner, in a building that is bigger than we need but well set up for us, and with what I think is a pretty good rate.

The new landlord thinks it’s an incredibly good rate and thinks the market rate (of course before this pandemic hit) should be closer to double what we are paying now. We have more than four more years left on our lease, and from his perspective, he might even prefer us to be out of the building. I suspect he has dozens or even more tenants from all over suddenly asking for reductions or notifying him that they won’t be able to make rent, and given his view of what we are paying relative to what the space is worth, we are going to be low on the list of tenants he wants to make special exceptions for. So for now, if we believe we can be back to full operation in the next few months and then resume the growth path we were on, it is very important for us not to give the landlord any pretext for evicting us. I realize some of what he told me might be for negotiation, but I believe he was generally up-front with me. (And I’ve been using the singular “owner” or “landlord” or “he” for the landlord in both the current and previous landlord cases, but really I am talking about my contacts for the ownership groups.)

I related the history of how we got here so that people who know more about this kind of thing might be able to give me better advice and so that people who look at some of the pictures I am posting don’t feel that we are wasting money on an extravagant work space. Yes, we could fit our current operations into a 50,000 square foot space. But building rent agreements can be quite long-term, and with the amount we have invested in equipment and improvements here, moving would be very expensive, even if we could find an appropriate space. And the value of our contract depends a lot on how things play out. If there is a long-term depression that we cannot survive, the contract is an anchor that will drag us down and potentially finish us. If things get better relatively quickly, the contract protects us and gives us stability, letting us operate at a relatively good rate, without having to interrupt everything to move.

I should also make sure it’s clear that I completely understand my landlord’s perspective (who of course has his own mortgages and employees to keep paying), and it’s good to know that he’s open to arrangements that could be mutually beneficial. Perhaps some more spaces will open up as other businesses close, and if we get forced to stop operating for an extended period of time, that interruption might also be a good time to move. For the time being, though, I think we just need to hang on for a few months, and if that is the case, we have to keep paying the full rent.

Stimulus bill and SBA disaster loan

After days of trying on the overloaded SBA disaster loan website, we got our loan application submitted at 2:30AM on Tuesday. It’s not clear how long it will be before there is some progress with that or how much assistance we would qualify for.

We are also paying attention to the new stimulus bill that was just passed to see how it might apply to us. So far, it looks like it will be at least a few more weeks before the details get worked out to a level that we can do something with. The initial impression I am getting is that the way the support is structured, we might be incentivized to do things that would be bad for us if the support doesn’t pan out. For example, it is paramount for us to cut back on expenditures so that we have some cash to pay the most critical bills as long as possible. That includes laying off non-essential staff right away. Yet that might reduce or even eliminate some of the support we might qualify for.

There’s also a huge difference between getting a loan and that loan being forgiven. If the model for our collective response to the pandemic is that the government orders us to pause operations, then gives me money to distribute to my employees, I am happy to do my part in that arrangement. If, on the other hand, the proposal amounts to me personally being on the hook for the rest of my life to pay back a loan I took just to pay people that weren’t allowed to work, that’s not actually helping, and it would make more sense for those employees to just get paid directly from the unemployment aspects of the support bill.

We might also be facing a situation where the new support measures might encourage people who could be working to stay home and collect unemployment instead. So far, we have gotten by without pushing anyone who does not want to be here to be here. This will be a challenge for society in general as we all try to pause and then recover in this unprecedented situation. Many individuals want to work, but it might be better for the community if they don’t, and in compensating them for preventing them from working, we might be discouraging other people whom we do need to be working.

Outlook and plan for now

The past two weeks of operation have made me optimistic that we could keep operating as we have for at least several more months. This past week was especially good because we had relative stability in how we operated, and it allowed us to spend a little time on getting ahead and start preparing for operating under these emergency measures for an extended period. A few engineers who had been working on production processes and were out the first week came in and started assessing our workflow with new distancing and isolation considerations. Having a lot of space is coming in handy, at least in terms of making it easier for people to work far apart from each other. We gathered in the same room once during the whole time, to select permanent spots in the break room:

|

Pololu skeleton crew permanent table assignment meeting, March 2020. |

|---|

(Those who have individual offices are encouraged to eat there, but in general, those are the people who are already home and connected remotely.)

We are also working on improving remote connection and working options where possible, including getting more computers and monitors to employees’ homes.

With the outlook unclear on how much government support we might get and when, it’s clear we need to transition to an operating mode where we can be largely self-sufficient financially without burning out before we get there. Here, the donations we have received have been tremendously helpful in buying us time to get back on our feet.

If you can, please consider donating to help Pololu make it. We have set up item 2400 for donating in $1 increments.

Other ways you can help

Pay now, ship later

In the past week, we added a feature to our online checkout system to allow for orders to be placed with a “pay now, ship later” option that lets you authorize us to charge the payment for an order as soon as it comes in, possibly well ahead of when the order would actually ship. We started working on this feature at a time when we thought complete shutdown of our operations was imminent, when it might have been weeks or even months before we could reopen. As I wrote at the top of this update, we have been able to ship all orders, and I expect to continue shipping, but this option still allows us to prioritize shipments and reduce stress with orders that come in later in the day and can get shipped the next day. We have already received dozens of orders with this option selected, and it is also encouraging just to see that our customers are trying to help us out. Thank you to all of you who have selected that option!

Order non-soldered versions of products, or the higher-stock versions

We offer a few of our products with some of the optional (but usually used) through-hole connectors soldered in. If you are able to solder, please consider ordering the non-soldered versions if there is plentiful stock of them. We do all of the through-hole soldering by hand, and most of our manual assemblers were older or otherwise in the higher-risk population for COVID-19, so they are not currently working here. And if you’re at home doing a non-critical project, now is a good time to do a little extra soldering, right?

On a related note, it’s a little bit easier for us if you order the item that has more stock. Going back to the screenshot I have at the beginning of this post, it’s easy to see our stock levels of similar products:

|

You can check available quantity of similar products on the parametric comparison table. |

|---|

If your application could get by with either an item of which we have 300 in stock or one of which we have 12 units, please get the product that we have much more of. It’s probably a more popular version that we make more often, and it keeps the less popular version available for those who might really need it.

Help each other on our forum

We have had to severely cut back on our technical support. If you are one those people with extra time on your hands now and are familiar with any of our products, please consider helping out our other customers on our forum.

Ask others to help us out

If you know anybody that could afford to help us out, please let them know and ask them to contribute.

Other suggestions and ideas

Part of the reason I went into more details in some areas is so you might be able to better give us advice about how we could make things better. Maybe you’re also working at a small business facing similar challenges, and you have some good suggestions. Maybe your uncle has a vacant building nearby. One suggestion I’ve heard repeatedly is about gift certificates, which we are looking into; if you know of particularly good ways of implementing that or things to be careful about, please let us know.

Thank you all for your support. Stay safe and healthy, everybody!

Please see new update posted Monday, 6 April 2020.

Coronavirus update - please help Pololu survive

TL;DR: Pololu is hurting. Skeleton crew is shipping important products to customers fighting COVID-19 around the world. Most employees facing layoffs. Please donate to help us keep operating and spread the word. Donate here.

|

Impromptu picture of most of the company from August 2019, when it was still safe for this many people to gather. |

|---|

Please see new update posted Sunday, 29 March 2020.

The last time I posted on this blog was in November 2018, sixteen months ago. We have been very busy at Pololu since then, and there is so much good and positive to share about what we did in 2019 and so far in 2020. Unfortunately, what is compelling me to post this update and plea for help is the COVID-19 coronavirus pandemic that is engulfing our planet.

Nevada, where we are located, was one of the earlier states to mandate sweeping reductions in activity, with the governor announcing on the night of Tuesday, March 17, that all nonessential businesses statewide were to shut down starting on Wednesday. We immediately began contacting all of our employees on Tuesday night not to come in the next morning while trying to plan for a shutdown of operations and looking for clarity about the extent to which the order applied to a company like Pololu. On Wednesday through Friday, we operated with a skeleton crew of around twenty of us, making sure we got orders out and received important incoming shipments.

Pololu is probably not the kind of company that first comes to mind when you think of Las Vegas. We design, make, and sell thousands of products from our location just a few miles from the famous Strip. Here is our building when I was locking up Friday night, with the light from the Luxor pyramid lighting up the clouds:

|

Pololu building exterior on the night of Friday, 20 March 2020. |

|---|

Inside, we have millions of dollars of equipment on which we have made millions of electronics boards that we have shipped all over the world. This is the newest of our three electronics production lines that we just finished setting up earlier this year, with machines that were all installed in 2018 and 2019:

|

Pololu’s newest SMT production line, March 2020. |

|---|

We have around two dozen pieces of big equipment, each one of which was a substantial undertaking just to install, with the electrical work alone costing tens of thousands of dollars in the most demanding cases. Here is the delivery of our latest laser cutter in November:

|

LaserCube delivery November 2019. |

|---|

We finally completed installation last month, and here is a picture I took for fun three weeks ago, with our first laser cutter from 2003 inside the new one:

|

Pololu’s first laser cutter from 2003 inside the newest one, March 2020. |

|---|

I post these pictures to help illustrate that an operation like ours takes a huge amount of effort to build up. I’ve been working on it for twenty years, and there are about 75 more people working on it with me now. We make and ship physical things, so we can’t just do this over a remote computer connection.

|

And what do we make? For the most part, we make components, like motor controllers and sensors, that go into bigger systems. We do not know most of the applications our products go into, and we cannot disclose some of the more intriguing ones that we do know about. But we have specific confirmation that our products are being used around the world in this fight against the new coronavirus, from components in prototypes for ventilators to components in PCR equipment, including ones used for coronavirus testing.

Are we essential, or essential enough to keep operating? With the changes we had already implemented prior to the governor’s order (for example, we suspended order pick-ups, so we are not open to the public), it seems clear that we are legally allowed to operate in accord with the clarifications the government has been issuing since Friday. Even before the ordered closures, we had done things like stagger our production work benches and spread out the tables in the break room:

|

Staggered workbenches in production area, March 2020. |

|---|

|

Spread out tables in break room, March 2020. |

|---|

(FYI several groups of our employees live and carpool together, so a few chairs at one table seemed ok to have as an option. We’re probably going to spread out chairs more and go to one assigned table per employee tomorrow.)

We are scrambling to stay in operation and to do it as safely and ethically as possible. The strain of trying to run this size of operation with two dozen people is enormous, especially while constantly having to prepare for being shut down externally and dealing with more and more uncertainties about components we need arriving. We are trying to get more people set up to work remotely, but I am posting these pictures to try to show how we cannot just run with remote workers. We are prioritizing shipping what was already made and making priority products that we know are for especially important customers.

I don’t know how much longer we will be able to run. Maybe a few more days? Perhaps even fewer of us can get some especially critical orders out for longer, as long as the shipping companies keep shipping our packages. Things keep changing, so it’s hard to say. But if we are not shipping orders, or just a small fraction of the usual ones, money won’t be coming in. I have told my employees that they should not count on another paycheck beyond the one they just got on Friday. We will keep paying for health insurance for everyone as long as we can, and we are looking into the ramifications that would have for things like unemployment insurance.

There is no way we can survive a shutdown of many weeks or even months. We tried to have redundancies in our operations, with as many backups as reasonable. We even have two compressors that we alternate each week, so that all our machines are not crippled if one of the compressors has an issue:

|

We alternate which compressor runs every week. |

|---|

But we just are not prepared for the level of shutdown we are facing. And so here I am, writing this post on Sunday night after coming up with a plan for tomorrow for my employees and writing to my landlord for help, begging anyone who reads this to help. I know many people and small businesses everywhere are hurting now. I am sure everyone who has put their life into their business feels like theirs is special. We have the facility and the machines and the people who know how to churn out millions of units of hundreds of designs that people around the world use. We have an awesome team. We just need the money to survive until we can start running again.

|

Pololu executive meeting Sunday morning, 22 March 2020. |

|---|

We are of course looking everywhere for help, and will be applying for whatever disaster relief is available as it becomes available. This is an unprecedented time for us, as I know it is for everyone. I know it is so much to ask for money with no strings attached, especially at a time like this, but that is what will most let us pay our obligations and our employees without diverting resources into extra accounting and agreements. We have set up an emergency product on our website that will allow anyone to donate money to Pololu.

You can use item 2400 to donate in $1 increments. This is still part of our regular website, so checkout will ask you for a shipping address, but there is now a “no shipment” option on the next step of checkout. We’ll work on making it smoother.

If you cannot personally donate, perhaps you know of someone who could. Maybe it’s someone who likes making things and wants to support a company like Pololu. Maybe it’s someone in Nevada who knows nothing about robotics but would like to support diversification of our economy. I threw this post together quickly and marketing was never my strong suit, but I will be updating our pages with more information about why Pololu is especially worthy of your support.

We (the off-site portion of the team!) will also be working on a feature to let you order non-critical items that we would ship once we can resume operations but with permission to charge your credit cards immediately so that we can keep our employees paid. (Update 3/25/20: This feature is now available. You can find the option during step 3 of checkout.)

If you got this far, thank you for your consideration and for any help you can give. Stay safe and try to be kind and useful to those around you.

Please see new update posted Sunday, 29 March 2020.

New products: Shunt Regulators

|

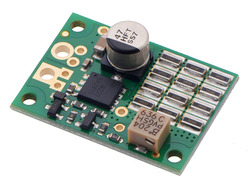

When I think of a robot, I usually picture a mobile robot, which generally means it is powered by a battery. Most of our motor controller products are built with that kind of bias in mind, too. But there are obviously many permanent installations that still call for motion, from 3D printers and robot arms to kinetic sculptures and motion simulators. And powering those can be complicated and expensive, with power supplies capable of powering bigger motors often costing more than the motors and the motor controllers. One difficulty is that power supplies are often not particularly good for absorbing the little pulses of power that motors and motor controllers sometimes send back out (typically when a motor is slowing down). The ramifications can be very bad since the supply voltages can quickly get destructively high when the current has nowhere to go. Many better power supplies have over-voltage protection, but that just means the power supply shuts down. While that’s better than expensive parts going up in smoke, it can still keep your project from functioning.

The simplest solution to the problem is often a transient voltage suppressor, or TVS, which is a big zener diode optimized for handling big current spikes. Unfortunately, TVS diodes typically do not have a tight enough tolerance for use with power supplies with over-voltage protection. For example, a 12V power supply might have 5% tolerance, meaning the output voltage could be as high as 12.6V, so the protection device must not kick in below 12.6V. If the over-voltage protection is triggered by a 15% deviation, any voltage spikes must be kept below 13.8V. Most basic TVSes do not have tight enough tolerances to ensure operation in that window.

So, we developed a shunt regulator that should help with that kind of scenario. A simplified schematic diagram of the shunt regulator is shown below. Basically, a circuit monitors the voltage and controls a MOSFET that allows current to flow through a shunt resistance that sets the maximum current the device can sink.

|

Simplified schematic diagram of the Shunt Regulators. |

|---|

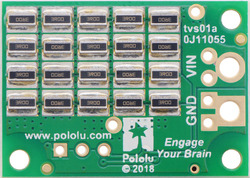

We offer the shunt regulators with a variety of voltage set points and shunt resistances. Available variations include fixed resistances and multi-turn potentiometers for the voltage set point, different shunt resistances for the load, and different power ratings for the shunt resistance (the higher-power versions have twenty more resistors populated on the back side of the board).

|

|

One version of the shunt regulator is populated with an especially high shunt resistance with minimal power rating; this unit is intended for use with an external shunt resistance:

|

Shunt Regulator: 33.0 V, 32.8Ω, 3W. |

|---|

The available versions are shown in the table below:

| Voltage | ||||||

|---|---|---|---|---|---|---|

| 13.2 V | 26.4 V | 33.0 V | Fine-adjust LV | Fine-adjust HV | ||

| Power | 3 W | – | – | #3780 32.8 Ω |

– | – |

| 9 W | #3770 1.33 Ω |

#3774 4.00 Ω |

#3776 4.00 Ω |

– | – | |

| 15 W | #3771 1.50 Ω |

#3775 2.80 Ω |

#3777 4.10 Ω |

#3778 1.50 Ω |

#3779 4.10 Ω |

|

This product is more for advanced users at this point since it can be difficult to determine how much power your motor is dumping back onto the power supply, but since we have the products working and several customers waiting to use them, we are going ahead with releasing them. We expect to develop additional resources and to put up verified regulator/motor controller combinations over time.

The basic regulators are quite inexpensive, and we are offering an introductory special as we are with all new products this year, so you might want to pick some up to play around with. The first hundred customers to use coupon code SHUNTREGS get 30% off on up to three units (per version).

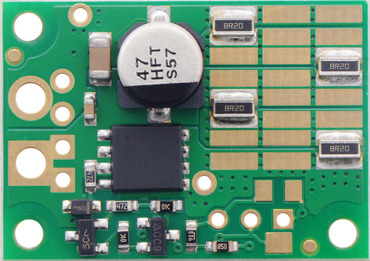

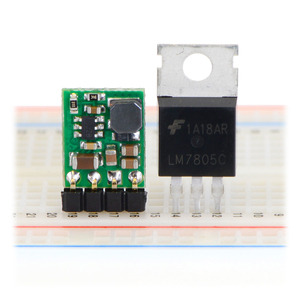

New products: D36V6x step-down regulators

|

Pololu step-down voltage regulator D36V6Fx/D24V6Fx/D24V3Fx next to a 7805 voltage regulator in TO-220 package. |

|---|

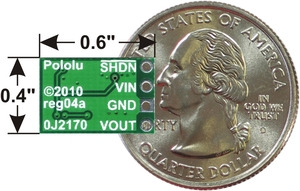

Wrapping up our new product releases for the month and for the summer is our new D36V6x family of step-down voltage regulators. These small regulator modules support a large input voltage range and are a great alternative to old three-terminal linear voltage regulators that waste a lot of power and get really hot. These new regulators can take an input voltage anywhere from a few tenths of a volt over the set output voltage up through an absolute max of 50 V, and they can deliver up to 600 mA. We have them available in seven fixed voltage options and two adjustable versions:

- D36V6F3: Fixed 3.3V output

- D36V6F5: Fixed 5V output

- D36V6F6: Fixed 6V output

- D36V6F7: Fixed 7.5V output

- D36V6F9: Fixed 9V output

- D36V6F12: Fixed 12V output

- D36V6F15: Fixed 15V output

- D36V6ALV: Adjustable 2.5 – 7.5 V output

- D36V6AHV: Adjustable 4 – 25 V output

|

Pololu step-down voltage regulator D36V6Ax/D24V6Ax/D24V3Ax, bottom view with dimensions. |

|---|

You might notice that the board for the adjustable version shows a 2010 copyright year (the fixed version is an even smaller board, and we did not fit the year on there). That’s because these new regulators are actually old designs updated with new regulator chips that use the same package and pinout. The older products were our D24V3x and D24V6x families of regulators, which were based on the Texas Instruments LMR14203 and LMR14206 ICs. For the new D36V6x family, we are moving up to the newer LMR16006 regulator. This chip has several exciting new features that we think will make it our favorite general-purpose regulator for many of our products: higher maximum voltage, better low-dropout performance, and better quiescent current.

Higher maximum voltage

The LMR16006 has a 60 V maximum input voltage, up from the 42 V of the LMR1420x parts. Even 42 V covered most of our typical applications, but it’s not quite enough for 36V nominal applications, which are getting more common. Our more advanced, integrated products such as motor controllers are often limited by some complex part or circuit, such as a motor driver, and we would like the overall operating range of the product not to be reduced by the regulator. Many stepper motor drivers, such as TI’s DRV8825 or the Toshiba TB67S249FTG and TB67S279FTG that we released carriers for in June, support maximum input voltages of 45 or 50 volts. It’s nice not to be limited by your regulator when you are making systems with those kinds of parts.

For our new D36V6x modules, we are limited to the 50 V maximum of the capacitors from Vin to ground. Unfortunately, capacitor options get a lot more restricted (and expensive) once we go beyond 50 V, so we decided to stick with our old boards so that we could continue to offer these regulator modules at a low price while still providing some substantial improvements. We might still make a new board with higher-voltage capacitors for those who would like to make full use of the regulator’s 60 V maximum. (For anyone thinking of just removing the caps and putting on your own external ones, you might also want to change the diode, which is also a 60 V part.)

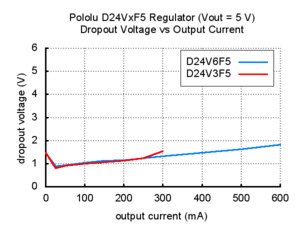

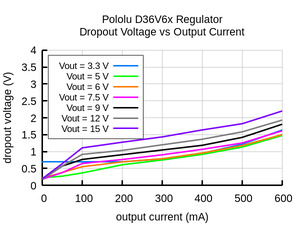

Better low-dropout performance

Having a higher maximum input voltage is nice, but often we’re trying to squeeze the most we can out of a dying battery, so it’s nice to have a low dropout, which is the voltage the regulator needs between the input and output. The older LMR1420x parts had an annoying quality of the dropout voltage going up as the load current went down. The newer LMR16006 has a nice, low dropout as the current goes down, so if you don’t need much current, you can get 5 V out with just 5.2 or 5.3 volts in. Here is a comparison of the dropout performance of the old and new regulators:

|

|

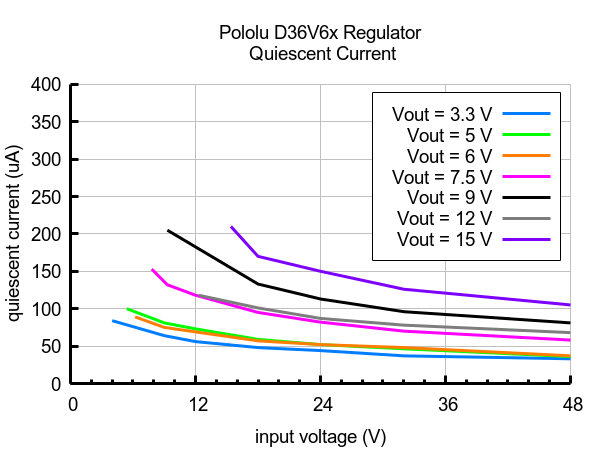

Lower quiescent current

The new regulators also have much lower quiescent current, which is the current the regulator uses when it’s just sitting there and your load isn’t drawing anything. On the old regulators, the quiescent current was under 2 mA, and we did not characterize it beyond that. For these new regulators, it’s typically under 200 microamps, ten to twenty times better than the old regulators. I realize it’s not that amazing for modern regulators, but it’s nice to know that your low-cost, general-purpose regulator module isn’t wasting a lot of power.

|

Typical quiescent currents of Step-Down Voltage Regulator D36V6Fx. |

|---|

Even when we put a new chip onto an old circuit board as I have described, we still test and characterize with different parts to get a good overall result. In the case of these regulators, where the circuit is quite simple, this phase of development is much more time consuming than laying out a circuit board. We build and test dozens of prototypes with different inductances, and even though you can’t see it in the pictures, we build the different voltage versions of the regulators with different inductors to get the best performance we can (within a given inductor type and size).

So how about getting a few to have around for general-purpose use on your next project? You can get one for just $3 as part of our introductory promotion using coupon code D36V6XINTRO, limited to the first 100 customers and to three per item (so you could get up to 27 regulators at that price if you get three of each voltage version). It’s always difficult for us to predict which versions will be how popular, so initial stock is limited, but we make these here in Las Vegas, so even if the version you want goes out of stock, you can backorder it with the promotional price, and we should be able to ship within a day or two.

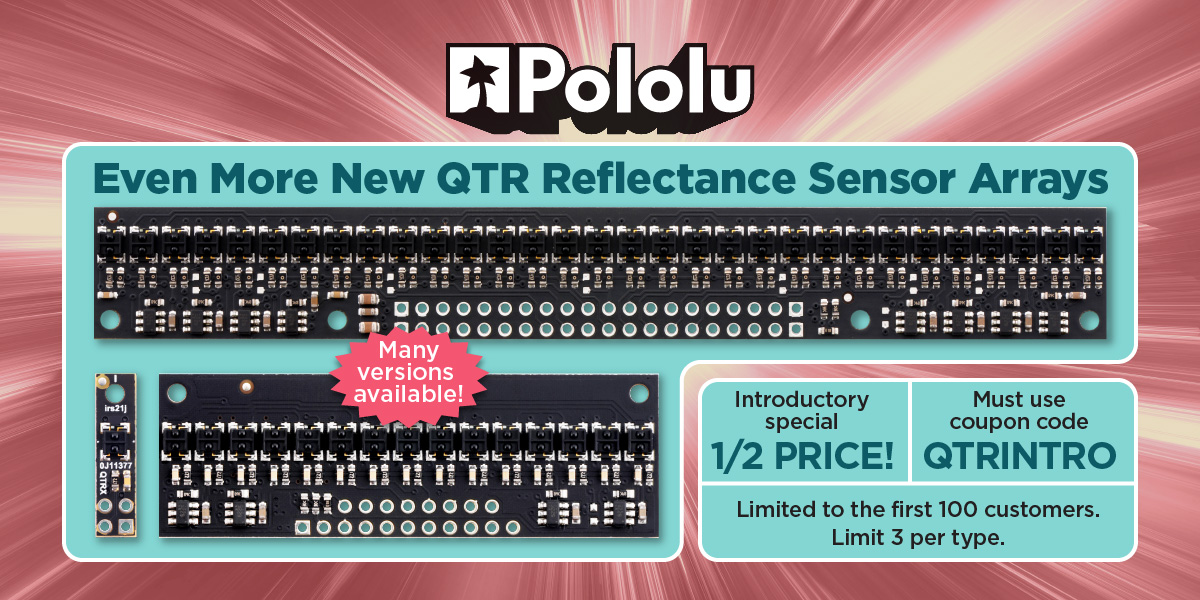

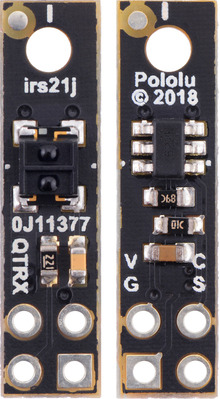

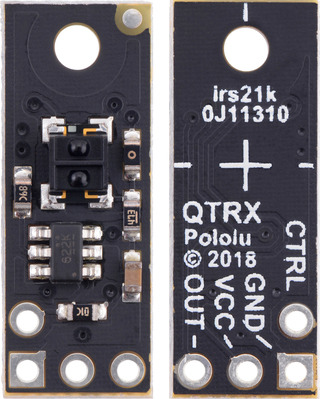

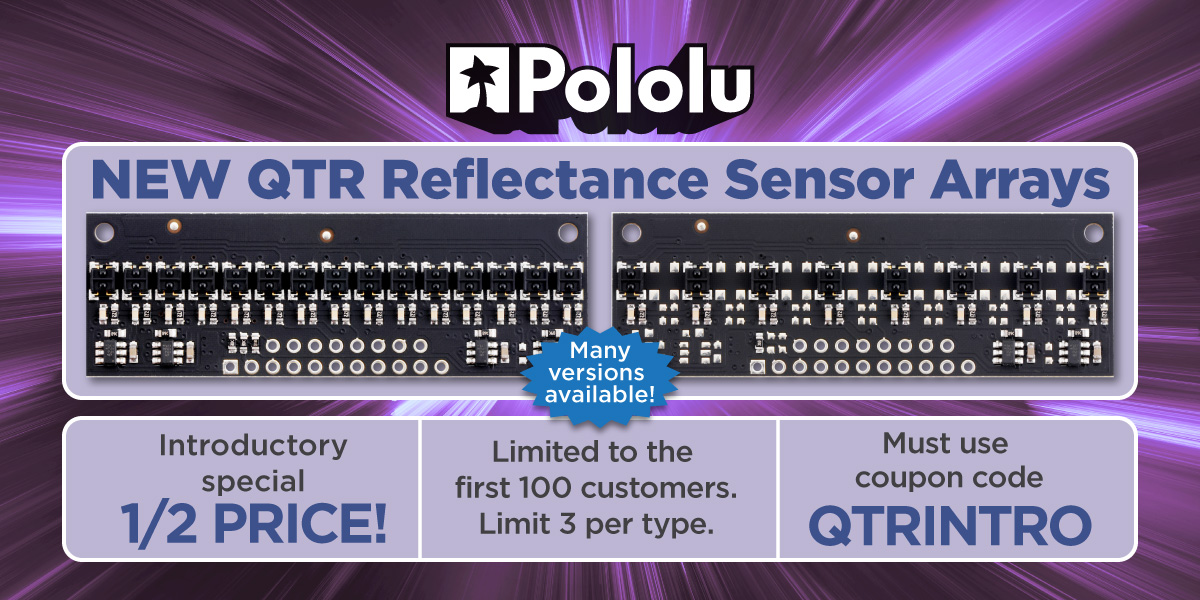

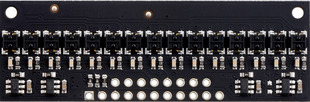

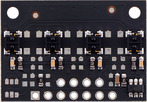

New products: 1- and 31-channel QTR HD reflectance sensor arrays

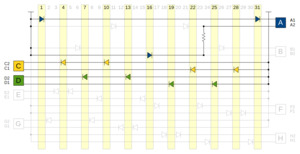

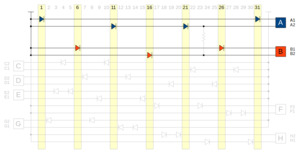

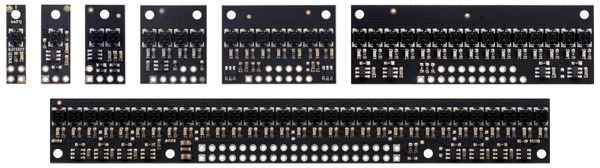

This week, we released what we expect to be the extremes of our new line of QTR HD reflectance sensor arrays, with two sizes of a single-sensor board on the small end and a massive 31-sensor array for the maximum size. This picture shows the relative sizes of the boards, along with some of the intermediate sizes we have available:

|

The QTR Reflectance Sensor Arrays are available in many different sizes. |

|---|

We made the two single-sensor sizes because we could make good arguments for each one. Part of the point of doing a single-sensor board is to make it really small, so you can fit it into tight spaces. But “really small” means different things depending on the dimensions you care about. So we have one version that is only 5 mm (0.2") wide, with components on both sides of the PCB, and one version that is 7.5 mm (0.3") wide, with components on just one side. The 7.5 mm wide version is a little thinner and flatter because it doesn’t have parts on one side, can be used with a 3×1, single row connector, and costs slightly less because of the single-sided assembly.

|

|

As I mentioned in some of my earlier posts (here and here) about this new line of sensor arrays, we are using two sensor types: more economical units we are calling “QTR”, and higher-performance units with lenses that we are calling “QTRX”. The main appeal of the QTRX sensors is that they can give the same readings at much lower IR emitter currents, which can really make a big difference for big sensor arrays. But if you crank up the current in those QTRX sensors, you can also get more distance. We did not do that on the QTRX arrays because the sensor modules leak light out the sides and interfere with each other when they are closely spaced, but with these single-channel boards, we are also making available the QTRX sensors with the higher 30 mA maximum emitter current, which allows for a range of up to about 8 cm (about 3 inches). We are calling these sensors QTRXL.

This video (taken with an old camera that does not have as much IR filtering as most newer cameras) shows the IR light leakage around the side of the QTRX sensor module:

I should point out that all of these new QTR modules offer variable brightness control by varying the current through the emitter using the control pin. However, if you want to take advantage of the maximum brightness and range, and have several sensors close to each other, you will need some barriers between them to prevent them from blinding each other (or just turn on one emitter at a time).

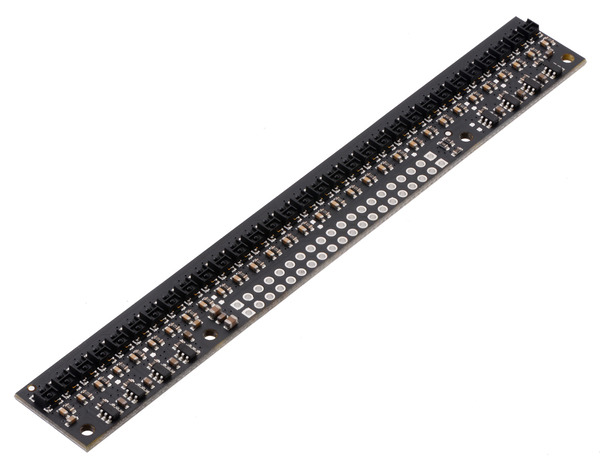

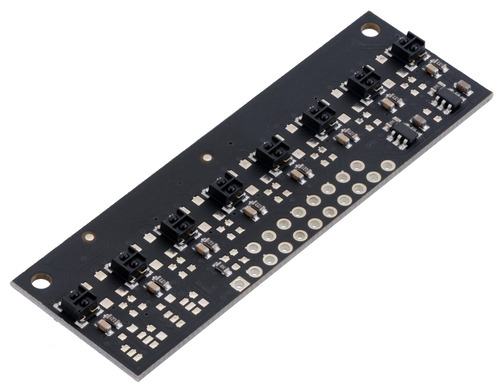

The 31-sensor arrays are huge! Well, at least compared to the tiny single-sensor boards.

|

QTRX-HD-31RC Reflectance Sensor Array. |

|---|

The routing on those boards is quite complex because adjacent IR emitters are not just wired in series (because we want to have separate even/odd emitter control, plus the alternate density population options I discussed in this post), so we ended up having to go to a 4-layer PCB to route it. This did let us make the vertical dimension a little lower, so the board is just 16.5 mm tall, compared to the 20 mm board height for the versions with 15 and fewer sensors. The 31-channel board is also 0.062" (1.6 mm) thick, compared to the thinner 0.040" (1 mm) boards we use for the lower channel counts. You can compare all the dimensions of the various boards in the detailed dimension diagram (2MB pdf).

The sixteen new boards we released this week brings the total available in this new QTR HD product line to 40. You can see the options neatly summarized in the tables below to pick the best array for your application.

| QTR sensors 2.9 V to 5.5 V; 30 mA max LED current(1); 5 mm optimal range |

|||||||||||||||||||||||||||||||||||||

| Board width |

Configuration | Max board current(2) |

Max range | Output type |

Name | 1-piece price |

|||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 5.0 mm | 1 sensor (HD) |

32 mA | 30 mm | analog | QTR-HD-01A | $3.25 | |||||||||||||||||||||||||||||||

| RC (digital) | QTR-HD-01RC | ||||||||||||||||||||||||||||||||||||

| 7.5 mm | 1 sensor (MD) |

32 mA | 30 mm | analog | QTR-MD-01A | $2.75 | |||||||||||||||||||||||||||||||

| RC (digital) | QTR-MD-01RC | ||||||||||||||||||||||||||||||||||||

| 10.2 mm | 4 mm × 2 |

32 mA | 30 mm | analog | QTR-HD-02A | $3.33 | |||||||||||||||||||||||||||||||

| RC (digital) | QTR-HD-02RC | ||||||||||||||||||||||||||||||||||||

| 17.0 mm | 4 mm × 4 |

62 mA | 40 mm | analog | QTR-HD-04A | $4.97 | |||||||||||||||||||||||||||||||

| RC (digital) | QTR-HD-04RC | ||||||||||||||||||||||||||||||||||||

| 29.0 mm | 8 mm × 4 |

62 mA | 40 mm | analog | QTR-MD-04A | $5.26 | |||||||||||||||||||||||||||||||

| RC (digital) | QTR-MD-04RC | ||||||||||||||||||||||||||||||||||||

| 4 mm × 7 |

125 mA | 40 mm | analog | QTR-HD-07A | $8.31 | ||||||||||||||||||||||||||||||||

| RC (digital) | QTR-HD-07RC | ||||||||||||||||||||||||||||||||||||

| 61.0 mm | 8 mm × 8 |

125 mA | 40 mm | analog | QTR-MD-08A | $9.90 | |||||||||||||||||||||||||||||||

| RC (digital) | QTR-MD-08RC | ||||||||||||||||||||||||||||||||||||

| 4 mm × 15 |

250 mA | 50 mm | analog | QTR-HD-15A | $16.88 | ||||||||||||||||||||||||||||||||

| RC (digital) | QTR-HD-15RC | ||||||||||||||||||||||||||||||||||||

| 125.0 mm | 4 mm × 31 |

495 mA | 50 mm | analog | QTR-HD-31A | $35.11 | |||||||||||||||||||||||||||||||

| RC (digital) | QTR-HD-31RC | ||||||||||||||||||||||||||||||||||||

| QTRX sensors 2.9 V to 5.5 V; 3.5 mA max LED current(1); 10 mm optimal range |

|||||||||||||||||||||||||||||||||||||

| Board width |

Configuration | Max board current(2) |

Max range | Output type |

Name | 1-piece price |

|||||||||||||||||||||||||||||||

| 5.0 mm | 1 sensor (HD) |

5 mA | 30 mm | analog | QTRX-HD-01A | $3.75 | |||||||||||||||||||||||||||||||

| RC (digital) | QTRX-HD-01RC | ||||||||||||||||||||||||||||||||||||

| 7.5 mm | 1 sensor (MD) |

5 mA | 30 mm | analog | QTRX-MD-01A | $3.25 | |||||||||||||||||||||||||||||||

| RC (digital) | QTRX-MD-01RC | ||||||||||||||||||||||||||||||||||||

| 10.2 mm | 4 mm × 2 |

5 mA | 30 mm | analog | QTRX-HD-02A | $4.99 | |||||||||||||||||||||||||||||||

| RC (digital) | QTRX-HD-02RC | ||||||||||||||||||||||||||||||||||||

| 17.0 mm | 4 mm × 4 |

9 mA | 40 mm | analog | QTRX-HD-04A | $8.25 | |||||||||||||||||||||||||||||||

| RC (digital) | QTRX-HD-04RC | ||||||||||||||||||||||||||||||||||||

| 29.0 mm | 8 mm × 4 |

9 mA | 40 mm | analog | QTRX-MD-04A | $8.41 | |||||||||||||||||||||||||||||||

| RC (digital) | QTRX-MD-04RC | ||||||||||||||||||||||||||||||||||||

| 4 mm × 7 |

17 mA | 40 mm | analog | QTRX-HD-07A | $14.05 | ||||||||||||||||||||||||||||||||

| RC (digital) | QTRX-HD-07RC | ||||||||||||||||||||||||||||||||||||

| 61.0 mm | 8 mm × 8 |

17 mA | 40 mm | analog | QTRX-MD-08A | $16.22 | |||||||||||||||||||||||||||||||

| RC (digital) | QTRX-MD-08RC | ||||||||||||||||||||||||||||||||||||

| 4 mm × 15 |

34 mA | 50 mm | analog | QTRX-HD-15A | $29.10 | ||||||||||||||||||||||||||||||||

| RC (digital) | QTRX-HD-15RC | ||||||||||||||||||||||||||||||||||||

| 125.0 mm | 4 mm × 31 |

68 mA | 50 mm | analog | QTRX-HD-31A | $60.01 | |||||||||||||||||||||||||||||||

| RC (digital) | QTRX-HD-31RC | ||||||||||||||||||||||||||||||||||||

| QTRXL sensors 2.9 V to 5.5 V; 30 mA max LED current(1); 20 mm optimal range |

|||||||||||||||||||||||||||||||||||||

| Board width |

Configuration | Max board current(2) |

Max range | Output type |

Name | 1-piece price |

|||||||||||||||||||||||||||||||

| 5.0 mm | 1 sensor (HD) |

32 mA | 80 mm | analog | QTRXL-HD-01A | $3.75 | |||||||||||||||||||||||||||||||

| RC (digital) | QTRXL-HD-01RC | ||||||||||||||||||||||||||||||||||||

| 7.5 mm | 1 sensor (MD) |

32 mA | 80 mm | analog | QTRXL-MD-01A | $3.37 | |||||||||||||||||||||||||||||||

| RC (digital) | QTRXL-MD-01RC | ||||||||||||||||||||||||||||||||||||

| 1 Can be dynamically reduced to any of 32 available dimming levels. 2 With all LEDs on at max brightness setting. |

|||||||||||||||||||||||||||||||||||||

Our introductory promotions are still going strong! Be one of the first 100 customers to use coupon code QTRINTRO and get any of these new sensors at half price! (Limit 3 per item per customer.)

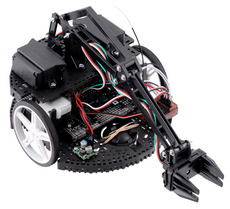

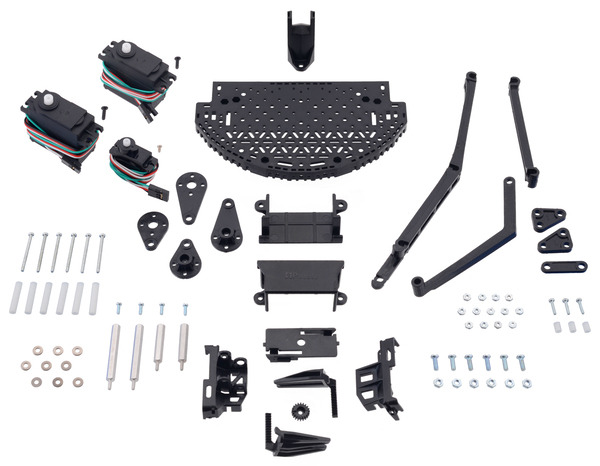

New products: Robot Arm Kit for Romi (and also just the gripper)

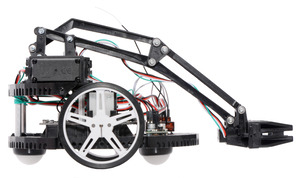

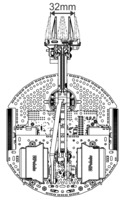

I’m super excited to announce our newest product, the Robot Arm Kit for Romi. The Romi arm is designed to mount to the back half of a Romi chassis with two fixed servos controlling the height and angle of the gripper through a nifty linkage system.

|

|

The gripper itself uses a micro servo with two parallel fingers or paddles that open and close through a rack and pinion arrangement. Here is a quick video demonstration of a Romi chassis with the arm attachment:

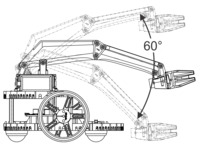

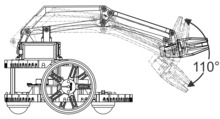

You can see the available range of motion in the drawings below:

|

|

|

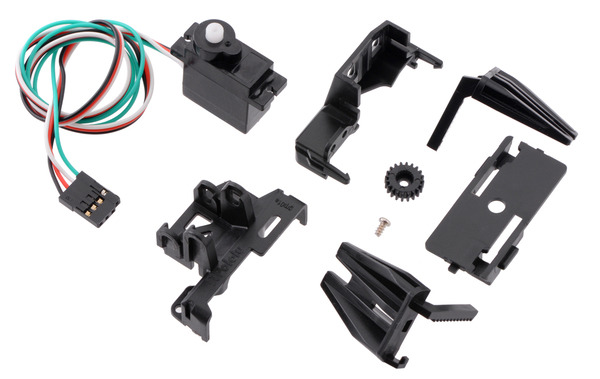

The kit ships with all mechanical parts, including special servos with a fourth wire for reading the position of the output shaft:

|

Contents of the Robot Arm Kit for Romi. |

|---|

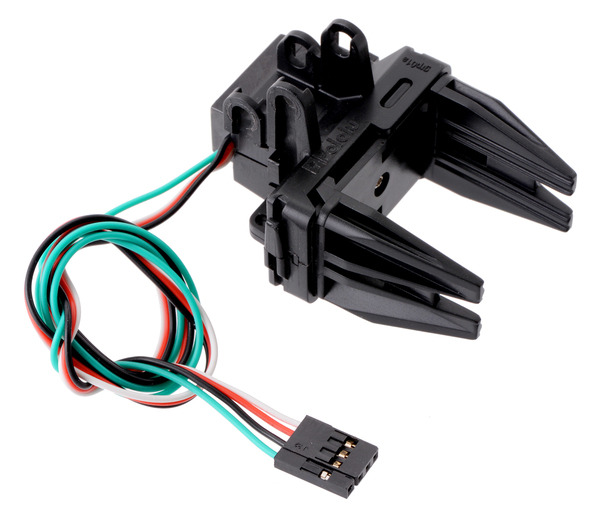

We are also making the gripper used on the arm available as a standalone Micro Gripper Kit with Position Feedback Servo. Here is a picture of the assembled gripper:

|

Fully assembled Micro Gripper with Position Feedback Servo. |

|---|

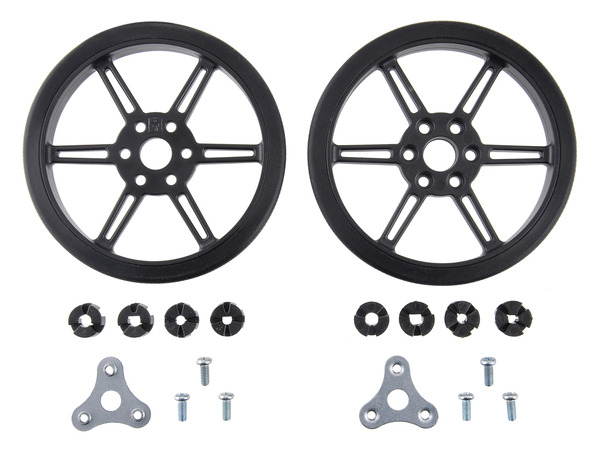

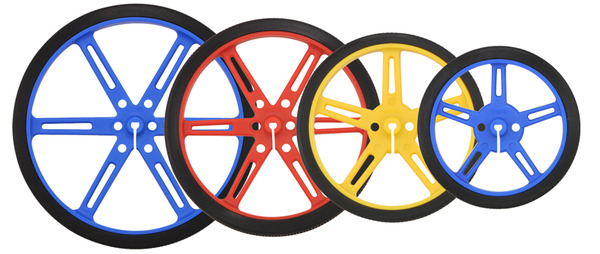

Products like this arm kit, with many injection-molded components, are some of the most complicated and time-consuming products we make. As those of you who have followed our growth over the past decade are probably aware, we try to develop our more complete robot kits incrementally, starting with components like just a wheel or a motor bracket, and then using those components in the more integrated robots. For example, we came out with this line of wheels in 2010:

|

Pololu Wheels with 90, 80, 70, and 60 mm diameters in three colors: blue, red, and yellow. |

|---|

The Romi and Balboa robots, which use those wheels, did not come out until 2016 and 2017.

|

|

If you look at the parts that go into just the gripper portion, you can see that each of the components is roughly as complicated as one of those wheels, and you can’t really do much with just one of those parts:

|

Contents of the Micro Gripper Kit with Position Feedback Servo. |

|---|

So, a lot of work goes into designing these kits. We also do not machine the molds or do the injection molding in-house (we did that on the first few parts for the 3pi robot), so that adds a lot of delays compared to our electronics boards, which we make in the same building that we design them in. We do 3D print prototypes to maximize the chances that we get the designs right, but there are invariably little modifications that we end up having to make when the components are this complicated, which is why it takes us years to go from the initial idea to the released kit.

We are at least sticking to our incremental product release approach as far as integration with electronics goes: at the time of the Romi arm attachment release, we do not have a specific solution for controlling the robot, which we will be working on next. Therefore, this kit is currently intended for advanced users who are comfortable powering and controlling several servos on their own.

As with all of our new product releases this year, we are offering substantial introductory discounts for the first customers to try out our new designs. You can use coupon code ROMIARMINTRO to get the whole arm for just $49 and code GRIPPERINTRO to get just the gripper for only $13. Each coupon is limited to 100 uses and 3 units per customer.

New products: more new QTR HD sensor arrays by student engineering interns

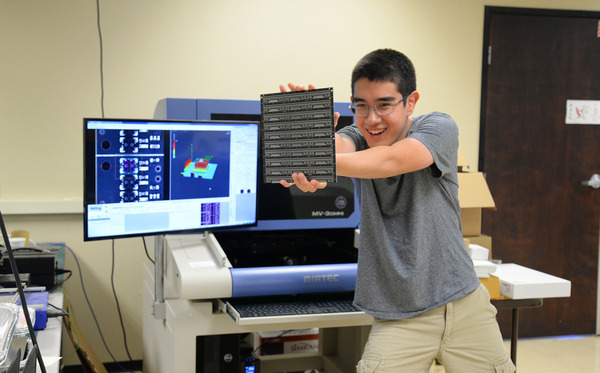

All the student engineering interns we had over the summer from out-of-town colleges are headed back to school, so I get to announce the release of products they worked on over the summer. The new QTR sensors we are releasing today include the 15-channel version laid out by seventeen-year-old Chris H.

|

Hadouken! (2018 summer engineering intern Chris couldn’t come up with a clever pun to use for this picture of him posing with a circuit board he designed.) |

|---|

You can see more about our new line of QTR reflectance sensor arrays in the first blog post I wrote about them a few weeks ago. One cool design and manufacturing aspect I did not mention then is that we designed these boards so that they could be populated at various densities. For example, that lets us make an 8-channel version with 8 mm sensor pitch on the same board that also works as a 15-channel array with 4 mm sensor pitch:

|

QTRX-MD-08RC Reflectance Sensor Array. |

|---|

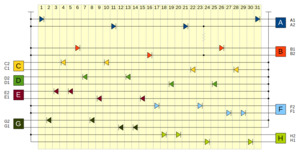

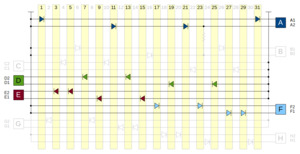

Here are some diagrams showing some of the thought that went into the soon-to-be released 31-channel version, which can also be populated to be an 8 mm pitch, 16-sensor array; a 12 mm pitch, 11-channel array; and a 20 mm pitch, 7-channel array:

|

|

|

|

With so many combinations of sensor types and output circuits, we won’t make every one of the possible arrangements a stock product, but the idea is that if you have an application where a particular sensor pitch is ideal for you, we can quickly make some for you without having to lay out new PCBs.

We expect eight channels on an 8 mm pitch to be a popular variant, so those will be stock products. We have also added the corresponding 4-channel version (using the same boards used for the full-density, 7-channel product), so this new product announcement covers twelve new stock sensor arrays:

|

|||

|

|||

|

Our introductory promotions are still going strong! Be one of the first 100 customers using coupon code QTRINTRO and snag any of these new sensors at half price! (Limit 3 per item per customer.)

New product: 80×10mm wheels with multi-hub inserts for 3mm and 4mm shafts

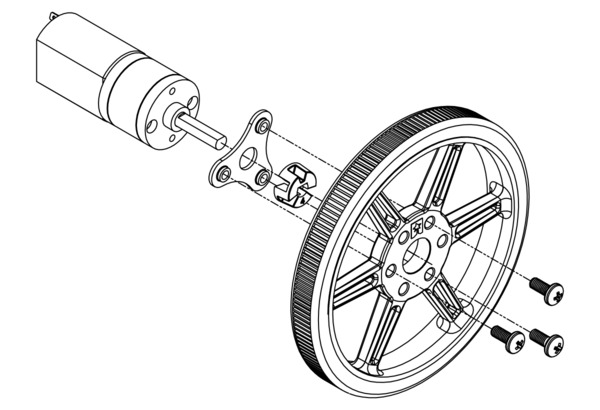

I have some exciting new wheels to tell you about (available as an 80×10mm black pair and an 80×10mm white pair). With a few small exceptions, all of the wheels we have made so far were for press fits (more properly called interference fit) onto 3mm D shafts such as those on our micro metal gearmotors. The press fit is simple and convenient for smaller motors and wheels, but there is an inherent trade-off between how hard you have to push to get the wheel on the shaft and how well the wheel stays on the shaft. As we contemplated designing some new wheels for our growing lines of 20D gearmotors and 25D gearmotors with 4mm output shafts (and higher power), I wanted something better. Our wheels already worked with our machined hubs with set screws, like this:

|

But the machined hubs are expensive, more expensive than the rest of the wheel. There’s also the much more minor issue of the machined hub option only allowing for the wheel to be placed at the very end of the shaft unless you drilled out the plastic wheel to have a hole larger than the shaft. I wanted to have an all-plastic, injection moldable solution that involved multiple parts that would somehow clamp the wheel onto an axle, kind of like a chuck on a drill.

My initial idea was to have just two parts: the outer wheel and an inner, interchangeable collet that would get wedged between the wheel and axle. But our mechanical engineers were not able to come up with a single part that could both compress onto the shaft and attach rigidly to the outer wheel. Because the parts are so small, the resolution of our 3D printer limited the effectiveness of prototypes, so we worked with scaled-up models. This picture shows one earlier model next to the final production parts for scale:

|

The other side of that model shows what we were thinking about for holding nuts in place on the back side of the wheel:

|

At that point, we were at a three-component design, plus the three screws and nuts, which was turning out to be difficult to assemble onto a shaft, even if it worked. The screw heads needed to be accessible from the outside of the wheel so they could be tightened, and that left the nuts near the motor where they were difficult to access, and trying to make the wheel hold the nuts required the wheel to be toward the motor and the collet piece on the outside, which was less aesthetically appealing.

So, in the end, we gave up on my all-plastic goal and designed a single stamped plate with threaded holes that clamps the wheel onto the collet insert. It definitely makes the assembly much easier, as you can see from this expanded view:

|

Having a design that seems like it might work on a 3D printed mock-up is still quite different from getting it working on the final, injection-molded parts. The clamping action of the collet inserts might have given us a little more margin for error than our usual press-fit wheels, but on those, a wrong fit is relatively straightforward to adjust: start with the fit a little on the loose side, and if it’s too loose, make the pin (and hole) smaller until it’s tight enough. With the new wheels, there were many more things that could go wrong, including alignment (wobbling). There was also the unknown of how much torque the hubs would take.

In the end, I think we arrived at a nice performance point. The wheels cannot take as much torque as if they were screwed on to the machined hub with set screw, but they can do much more than just the press fit hubs while putting less strain on the motor output shafts during installation. It’s possible to assemble the wheels with a little wobble, but if it’s a concern in your application, you can fiddle with how you tighten the three screws to get it as lined up as you like.

We started with our 80×10mm wheels, and made inserts that work with 3mm and 4mm shafts, both round and D-shaped:

|

Since the concept seems to be working, we will be working on different wheel sizes and inserts for larger shafts later this year.

As with all our new product introductions this year, we are having an introductory special. Be among the first 100 customers to use coupon code MULTIHUBINTRO (click to add the coupon code to your cart) and get 33% off on up to three sets.

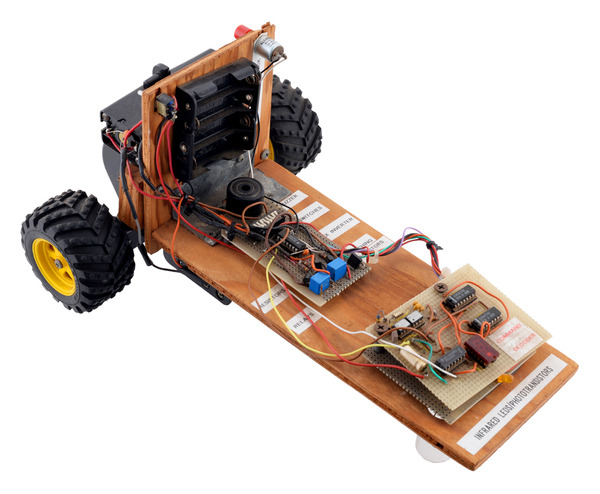

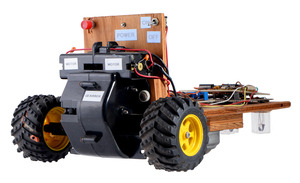

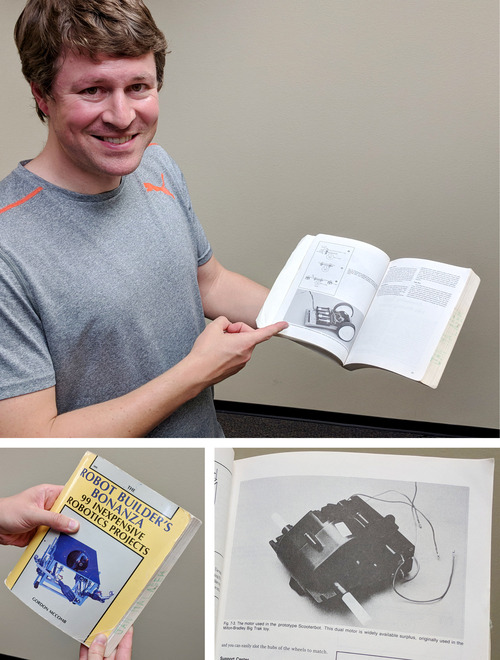

New product: Stability Conversion Kit for Balboa (and some memories of my first robot)

I don’t blame you if you have no idea why the new Stability Conversion Kit for Balboa is so exciting. With a name like that, you probably couldn’t even guess what it is, let alone why it’s exciting. But let me keep you guessing while I share a little about the first robot I built, which is kind of a hint. It’s pure coincidence that I happened to get reunited with it just as we were preparing to release this new product I’m announcing here.

I know for sure that I built my first robot in eighth grade, for the science and engineering fair for which everyone in my school had to do a project, which means I must have started working on it in 1992 when I was twelve years old. The better projects in my school went on to the local, island-wide science fair in Hilo, and the better projects there went on to the state fair in Honolulu. (I was initially not among those chosen to go on from the Big Island, I think because of some judging process mistake, but my science teacher and probably others lobbied to get me there.) There was time between the different stages, so I kept working on it through the spring of 1993, which would now make it over 25 years old. I probably added the labels in later stages in response to some advice to better present what I made.

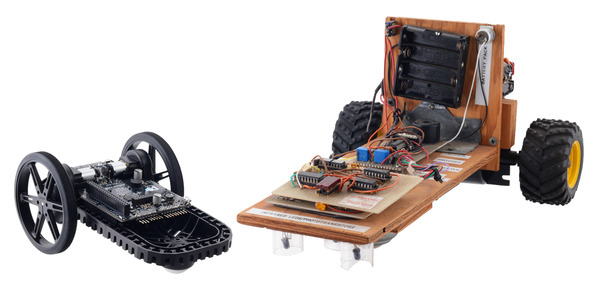

|

Jan’s first robot, “Robot Line Tracker,” built 1992-1993. |

|---|

|

When Paul saw the robot for the first time in my office this morning, he immediately recognized a piece of it: “That looks like the gearbox from my first robot!” I was a bit skeptical, but he immediately backed it up by pulling out Gordon McComb’s Robot Builder’s Bonanza and showing me the project he had followed from the book. (In another amusing twist, it turns out that the copy of the book Paul had in his office is my old book, though I hadn’t gotten it until high school, and I didn’t realize until today that the gearbox in the book was the same one I had used.)

|

I’m pretty sure I got the gearbox from Edmund Scientific, because their printed catalogs and Radio Shack (nearest one in Kona, 40 miles away) were initially my only sources for anything electronics-related. The wheels were from some broken radio control toy. The ball caster was long a point of frustration. In earlier versions of the robot, I had tried more common swivel casters and then a ball caster I made from a ping pong ball in a toilet paper tube, but neither was very reliable. I was very happy to eventually find the metal ball caster that I used in the final version, which you can see here along with the three IR LED and phototransistor pairs used for detecting a two-inch white line on a black background:

|

That heavy, noisy caster was not ideal, but at least it didn’t jam at a bad angle like the swivel caster or collapse like my ping pong ball and cardboard creations. I am mentioning all these details because it was so much work just to put a basic chassis together, without even getting to the electronics part. The electronics are not something I want to cover in this blog post, but I should mention that I was very fortunate to find a mentor at the Canada-France-Hawaii Telescope headquarters right across the road from my school. CFHT had a nice electronics lab stocked with all kinds of components they just gave me and tools they let me use, and I got lots of help from John Horne when I was in 8th grade and then from many others there while I was in high school.

So, to bring this back to Pololu’s new product: the Stability Conversion Kit for Balboa is primarily a ball caster attachment for the Balboa chassis:

|

That might sound pretty basic, but using it fundamentally transforms the Balboa into a very different kind of robot. As a reminder, Balboa is a two-wheeled, balancing robot:

|

You can read more about the balancing robot in my blog post introducing the Balboa robot. It’s a very capable platform that we spent many years developing, but making a balancing robot is not easy, and it’s probably not the best type of robot to build as your first robot. We did not even release the chassis as a separate product independent of electronics because it would be difficult to do much with it. The new stability conversion kit completely changes that. With the ball caster, the chassis can be used as a much more beginner-friendly differential-drive mobile base with three points of contact with the ground:

|

We offer the ball caster attachment by itself, for those who want to use it with a complete Balboa 32U4 robot kit to immediately get up and running without developing their own electronics. We also now offer the Balboa Chassis with Stability Conversion Kit, which includes all the mechanical components for the chassis other than wheels and motors:

|

Balboa Chassis with Stability Conversion Kit (No Motors, Wheels, or Electronics). |

|---|

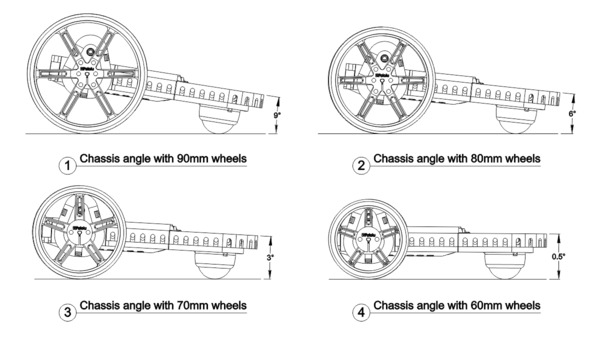

As with the original Balboa 32U4 kit that includes electronics, we deliberately do not include motors and wheels so that you can pick your own to customize the look and performance of your robot. This diagram shows the possible chassis angles with four different wheel sizes ranging from 60 mm through 90 mm:

|

Variety of chassis angles available when using different wheels on the Balboa Chassis with Stability Conversion. |

|---|

|

Micro Metal Gearmotor HPCB with extended motor shaft. |

|---|

For motors, we recommend our 30:1 HPCB, 50:1 HPCB, or 75:1 HPCB micro metal gearmotors with extended back shafts that can be used with encoders. Even if you do not plan on using encoders on your robot at first, it’s nice to have the option down the road.

And options are what our chassis kits are all about, whether you select our Zumo tracked chassis, Romi round chassis, or now the new Balboa chassis. One of my guiding principles in developing our robot platforms is that I want to help you, our customers, build your robot, not just the particular one we designed.

I realize there are many kids interested in robotics who are not as fortunate as I was to have Canada-France-Hawaii Telescope headquarters across the street from my middle school, and that for many of them (and their parents and teachers), all of the options we offer can be overwhelming. Over the next several years, we will be working on sensors and other modules specifically for the Balboa, along with combination bundles and tutorials that will make Balboa a platform that students can begin with as a basic first robot in middle school and keep expanding through higher levels of their education.

I’ll end this product introduction as I have all my product announcements this year, with an introductory special to encourage you to try the Balboa chassis out for yourself. Be among the first 100 customers to use coupon code BALBOACHASSIS (click to add the coupon code to your cart) and get 15% off on Balboa-related products (limit 4 per product).