Pololu Blog »

Pololu Blog (Page 28)

Welcome to the Pololu Blog, where we provide updates about what we and our customers are doing and thinking about. This blog used to be Pololu president Jan Malášek’s Engage Your Brain blog; you can view just those posts here.

Popular tags: community projects new products raspberry pi arduino more…

New track sets and colorful Zumo sprockets

|

|

|

|

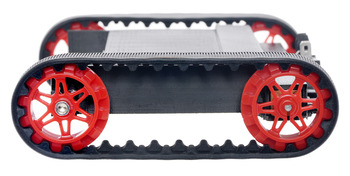

Pololu 22T Track Set – Red. |

|---|

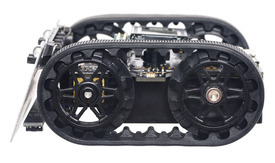

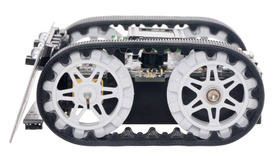

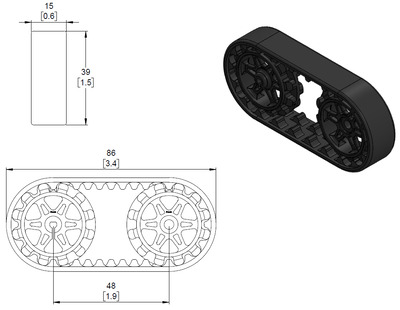

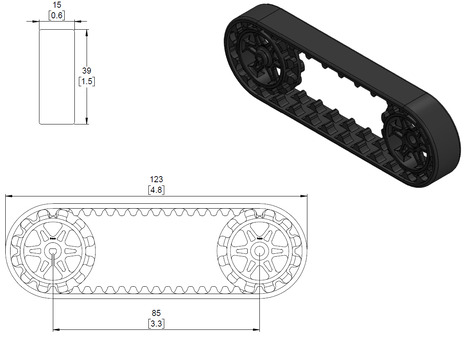

We have replaced our original Pololu track sets with new versions featuring our newer style of spoked Zumo sprockets. The sprockets are available in three colors, and like our original sets, we have two different track lengths to choose from:

- 22T tracks with black sprockets

- 22T tracks with red sprockets

- 22T tracks with white sprockets

- 30T tracks with black sprockets

- 30T tracks with red sprockets

- 30T tracks with white sprockets

Each track is made of a single piece of flexible silicone, and the drive sprockets are designed to work with 3mm D-shafts, such as those on our micro metal gearmotors and most of our mini plastic gearmotors.

|

|

Additionally, we are offering sprockets by themselves (without tracks or fasteners) for use as replacements for the black sprockets included with our Zumo robots: you can use the red sprockets to add a splash of color, and you can use the white sprockets for painting (or just leave them white!).

|

|

High-altitude balloon for the solar eclipse

This summer, Jon and I participated in NASA’s nationwide Eclipse Ballooning Project with the University of Nevada. Specifically, we were members of the University of Nevada, Las Vegas (UNLV) section of Nevada’s team which also had a section from the University of Nevada Reno (UNR). Our goal was to make a payload to collect interesting video footage and scientific data, then fly that payload on a high-altitude balloon that would ascend to around 100,000 ft in the totality zone during the 2017 solar eclipse on August 21. Continued…

Labor Day weekend sale

We are having a Labor Day sale all weekend long with site-wide discounts of up to 25%! Check out the sale page for more information. Please note that we will be closed Monday, so orders placed after 2 PM Pacific Time today (Friday, September 1) will be shipped on Tuesday, September 5.

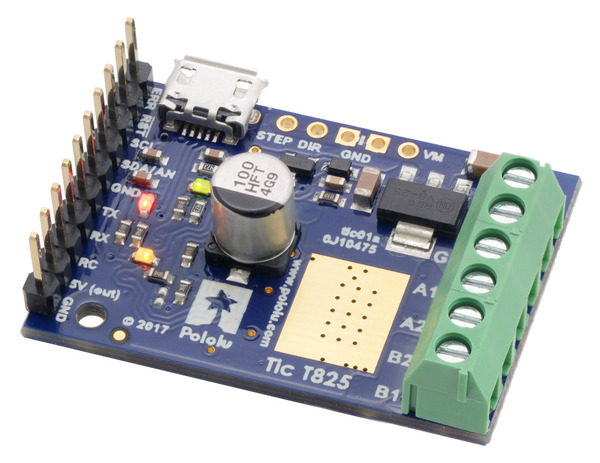

Introducing the Tic T825 USB Multi-Interface Stepper Motor Controller

I am excited to announce our new product, the Tic T825 USB Multi-Interface Stepper Motor Controller. The Tic makes basic speed or position control of a stepper motor easy, with support for six high-level control interfaces:

- USB for direct connection to a computer

- TTL serial operating at 5 V for use with a microcontroller

- I²C for use with a microcontroller

- RC hobby servo pulses for use in an RC system

- Analog voltage for use with a potentiometer or analog joystick

- Quadrature encoder input for use with a rotary encoder dial, allowing full rotation without limits (not for position feedback)

You can select which of these interfaces you want to use and configure the other settings of the Tic over USB using our free software.

|

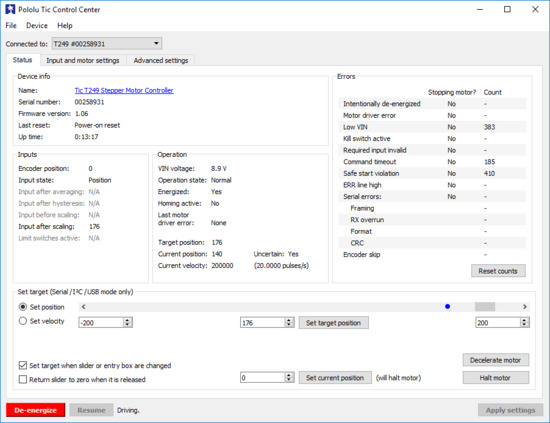

The Status tab of the Pololu Tic Control Center. |

|---|

|

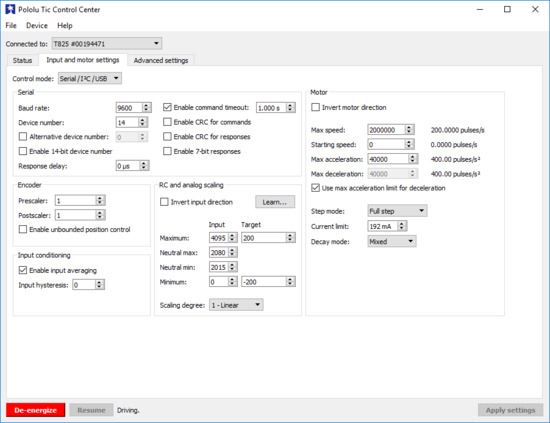

The Input and Motor Settings tab of the Pololu Tic Control Center. |

|---|

The Tic T825 can operate from 8.5 V to 45 V and deliver up to approximately 1.5 A per phase continuously without a heat sink or forced air flow. With a digitally adjustable current limit that can be set over USB, serial, or I²C, you can save power while holding position or increase the motor’s torque while it is moving. The Tic offers six different step resolutions, from full step through 1/32-step (32 microsteps per full step). We designed the Tic’s firmware to be capable of taking up to 50,000 microsteps per second, which lets you use those finer microstepping modes while still keeping a high motor speed. The Tic also supports acceleration and deceleration limiting for smooth movements, and very slow speeds down to 1 step every 200 seconds (or 1 step every 1428 seconds with reduced resolution). The Tic T825 is based on the DRV8825 stepper motor driver IC from Texas Instruments (for which we also have a basic carrier board), and we plan to make other versions of the Tic that are based on different drivers with different performance characteristics.

|

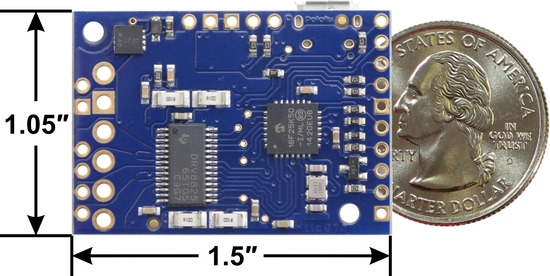

Tic T825 USB Multi-Interface Stepper Motor Controller, bottom view with dimensions. |

|---|

The Tic T825 is available with connectors soldered in or without connectors soldered in.

For RC/hobby servos, we have a similar family of products called the Maestro servo controllers. For brushed DC motors, we offer the Simple Motor Controllers and the Jrk Motor Controllers.

Independence Day weekend sale

In celebration of Independence Day (July 4th), we are discounting selected products by up to 25% and offering an upgrade to the next best price break for everything else in our store. Please note that we will be closed Tuesday, so orders placed after 2 PM Pacific Time on Monday, July 3 will be shipped on Wednesday, July 5.

For more information, including all the discount coupon codes, see the sale page.

|

Happy 4th of July!

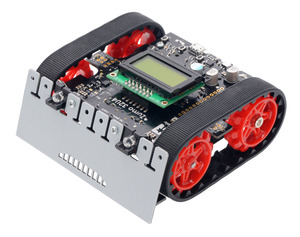

Zumo 32U4 Robot for RoboFest's RoboHit competition

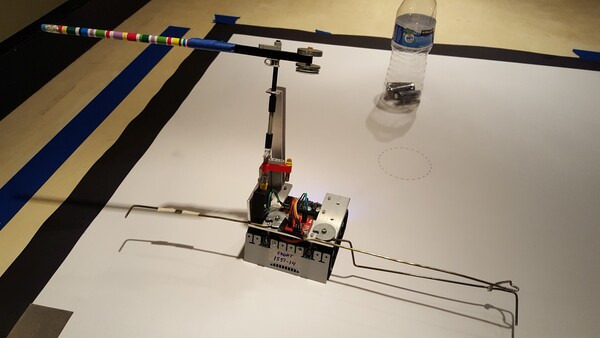

We were excited to hear from the NCA Lights high school student robotics team about their recent entry in the RoboFest Michigan Championship 2017 RoboHit competition. RoboFest is a series of robotics events and competitions organized by Lawrenece Technological University. This year’s baseball-themed competition, “RoboHit”, involved hitting a ping pong ball off of a water bottle with a pencil and circling the outer edge of the arena (base running).

The NCA Lights used a Zumo 32U4 Robot Kit and two 50:1 Micro Metal Gearmotors HPCB 6V with Extended Motor Shaft as the base of their robot.

|

Memorial Day weekend sale

We are having a big Memorial Day sale now through Tuesday, with discounts on over 1000 products when you use the coupon code MEMORIALDAY17. Stock up on robot parts now so you can build cool things all summer long! Note that we will be closed on Monday, so orders will not ship until Tuesday, May 30.

For more information, including all of the sale items, see the sale page.

Open-source myoelectric hand prosthesis

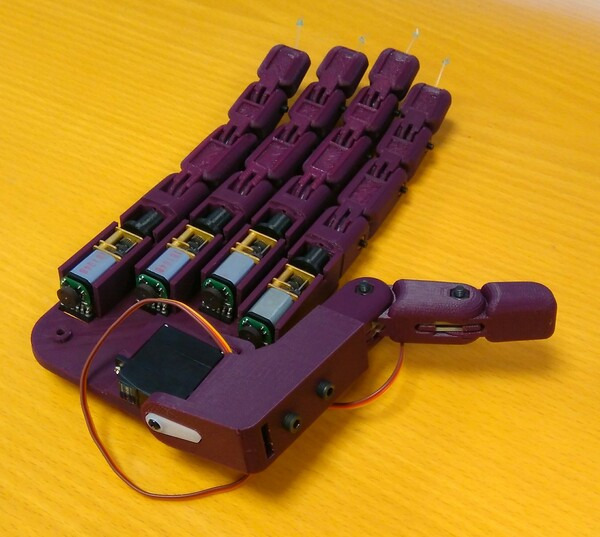

Pololu customer Alvaro Villoslada made this impressive open-source 3D-printable hand prothesis. Each finger uses a 1000:1 Micro Metal Gearmotor HP 6V with Extended Motor Shaft to wind a fishing line—acting as a tendon—onto a spool. A magnetic encoder attached to each motor enables closed-loop control, and the motors are driven by DRV8838 DC motor driver carriers. An RC hobby servo controls the thumb position. Alvaro uses a Teensy 3.1 microcontroller to monitor the encoders and control the actuators, and he built a user interface in Python for controlling the hand from a computer.

|

For CAD files, detailed instructions and more pictures and videos, see the Hackaday project page.

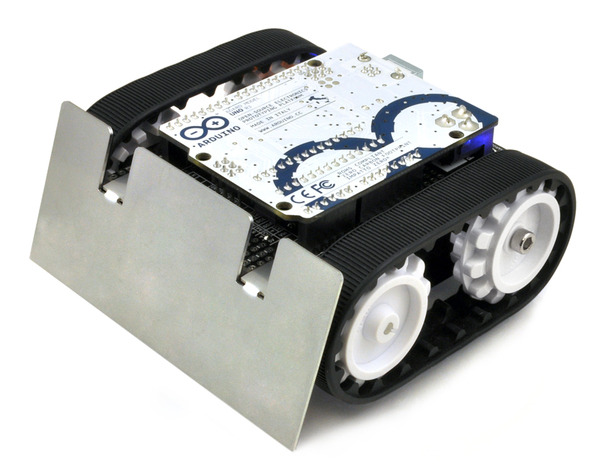

Guide utilisateur du Robot Zumo Pololu

|

MCHobby, a Pololu distributor, translated the Pololu Zumo Shield for Arduino User’s Guide to French as the Guide utilisateur du Robot Zumo Pololu (2MB pdf)! They describe it in French as “Un guide complet pour assembler, utiliser et exploiter rapidement votre Robot Zumo (version 0.1)”. If you’d like to see more translations like this, please let them you know that you enjoyed it and support them by buying from their shop.

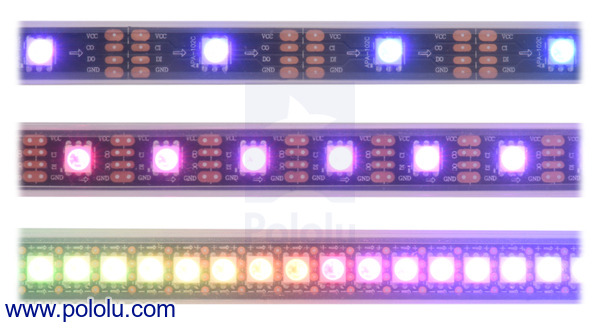

New SK9822 LED strips and panels

We’re excited to offer a series of addressable LED strips and addressable LED panels based on the new SK9822 integrated circuit. Like the APA102C, the SK9822 combines an RGB LED and driver into a single 5050-size package, allowing each pixel to be individually controlled using a simple two-wire SPI protocol.

The SK9822 is almost (see the notes below) a drop-in replacement for the APA102C and is better than it in a few ways, most importantly its built-in constant current control. If you’ve ever tried to power a long chain of LED strips and only connected power at one end, you might have noticed that the far end of the LED strip has a lower voltage across its power rails because of resistance in the long power connections. For LED strips based on the APA102C and WS2812B, the lower voltage makes the light dimmer and redder. With the SK9822, voltage drops like that are less likely to have a visible effect as long as the voltage stays above 3.5 V.

The SK9822’s protocol is very similar to that of the APA102C, but it updates the color that is being shown at a different time. If you replace APA102C LEDs with SK9822 LEDs in a low frame-rate application, you might have to update the code you are using to control the LEDs. The latest version of our APA102 Arduino library works with the SK9822 so you can either use it directly or use it as a reference when writing your own code. The colors generated by the SK9822 look different from the colors generated by the APA102C, so we would not recommend mixing the APA102C and the SK9822 in a single project.

We offer six different kinds of SK9822 LED strip with different LED densities and lengths:

- 1 meter, 30 LEDs (30 LEDs/m)

- 2 meters, 60 LEDs (30 LEDs/m)

- 5 meters, 150 LEDs (30 LEDs/m)

- 1 meter, 60 LEDs (60 LEDs/m)

- 2 meters, 120 LEDs (60 LEDs/m)

- 0.5 meters, 72 LEDs (144 LEDs/m)

We offer SK9822 LED panels in three different sizes:

These new SK9822-based products will replace our older APA102C-based products.

We continue to offer SK6812-based LED strips which also have constant current control but are controlled with a one-wire protocol.

|

Close up of an SK9822, with the red, green, and blue LEDs on at a low brightness. |

|---|

|

An addressable RGB LED strip (APA102C or SK9822) displaying a rainbow animation. |

|---|