Pololu Blog »

Pololu Blog (Page 9)

Welcome to the Pololu Blog, where we provide updates about what we and our customers are doing and thinking about. This blog used to be Pololu president Jan Malášek’s Engage Your Brain blog; you can view just those posts here.

Popular tags: community projects new products raspberry pi arduino more…

New 3pi+ 32U4 OLED Robot with graphical display!

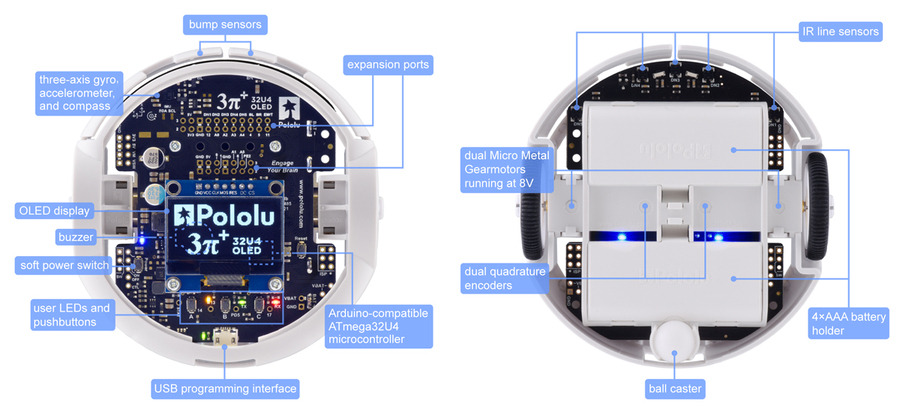

We are very excited to announce that the 3pi+ 32U4 OLED Robot is now available! This is an updated version of the original 3pi+ 32U4 Robot that replaces the old LCD with a monochrome 128×64 OLED display, giving it the ability to display fancy high-contrast graphics while following a line course, navigating a maze, or doing whatever it is that you want this compact but versatile mobile platform to do.

|

|

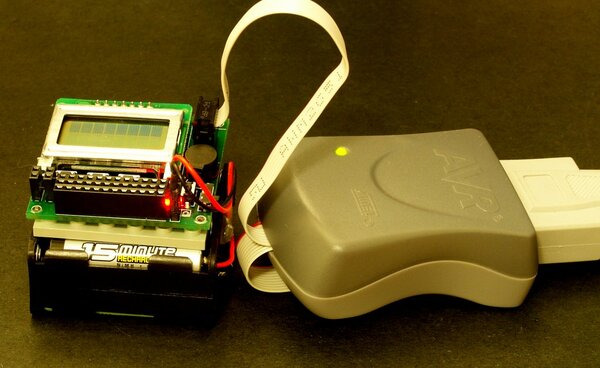

For more than 16 years, starting with some of our oldest products (from well before I joined Pololu), we have used HD44780-compatible alphanumeric liquid crystal displays on our robots and robot controllers. These LCDs have been around forever and are limited to displaying simple text on a fixed grid, but they are also ubiquitous: there are plenty of manufacturers still making displays that use the standard HD44780 interface.

|

Pololu Orangutan Robot Controller connected to an AVR ISP (serial version). |

|---|

It’s unlikely that we would have much difficulty sourcing this kind of display any time soon (as long as the pandemic doesn’t mess things up too badly), so using them in our products has always been a safe option despite their graphical limitations. The original 3pi+ 32U4 that we released late last year was our most recent design to include LCD support.

Meanwhile, monochrome organic light-emitting diode (OLED) displays have become increasingly popular in electronics over the last decade or so, and it’s not hard to see why: you can draw graphics on them, they can fit more information on the screen, they’re easier to read in the dark, and they just plain look cooler. But even though you might be able to go to eBay or Amazon and order a cheap OLED display for your project when you want one, it’s critical that we find a dependable supplier for a component like this before we can start to design it into our products.

That is why the availability of the 1.3″ OLED module we announced recently was actually a pretty big deal for us: it means that we finally have a source that we can rely on for larger quantities of these displays. The 3pi+ 32U4 OLED is the first of what we hope will be many robots and control boards that make use of the graphical capabilities offered by an OLED screen.

|

Like the original 3pi+ 32U4, the newer OLED version is available with three different motor options, either fully assembled or as a kit:

| 3pi+ 32U4 OLED Version | Products | Micro Metal Gearmotor | Top Speed | Comments |

|---|---|---|---|---|

| Standard Edition | assembled or kit | 30:1 MP 6V | 1.5 m/s | good combination of speed and controllability |

| Turtle Edition | assembled or kit | 75:1 LP 6V | 0.4 m/s | longest battery life, easiest to control, good for swarm robots or introductory robotics courses |

| Hyper Edition | assembled or kit | 15:1 HPCB 6V | ~4 m/s | very fast and difficult to control, easy to damage; only recommended for advanced users |

For anyone who wants to use different motors than the options above, the 3pi+ 32U4 OLED control board is likewise available separately and can be combined with a 3pi+ chassis and a pair of motors to build a custom robot.

We will be phasing out the original 3pi+ 32U4 robots and kits (they will remain available by special order), but that does not mean the old versions are suddenly obsolete or that you will have to learn an entirely new platform to use the new OLED version. Aside from the display interface, the hardware on the LCD and OLED versions is exactly the same, with features including encoders, line sensors, front bump sensors, and a full IMU (inertial measurement unit).

From a software perspective, it can actually be pretty challenging to work with graphics, especially on a small processor like the ATmega32U4. The simplicity of a text LCD can be an advantage in that you can essentially just ask it to do something like printing the letter “A” on the first column of the second row. On a graphical display, even if you just want to show some text, you have to define the shape of the letter in pixels; optionally composite that shape into a memory buffer; and then send the complete pixel data to the display. That means you have a lot more control over how that letter “A” is shown, but it takes a lot more work to do it.

To help get you started, we’ve developed an LCD compatibility layer as part of our Arduino library for the 3pi+ 32U4. This makes it easier to use the OLED screen for common display tasks, and it’s straightforward to write programs that will work on either version of the robot with minimal changes, since you can update an existing program to run on the OLED version by changing just a single line of code.

|

A 3pi+ 32U4 OLED and an original 3pi+ 32U4 running nearly identical programs and displaying the same text. |

|---|

Additionally, the same library makes it trivial to get the benefit of a higher-density text area: you can easily “upgrade” from an 8×2 character grid to an 11×4 or 21×8 layout.

|

Higher-density text layouts on the displays of some 3pi+32U4 OLED robots. |

|---|

We plan to continue improving our libraries to give you more options for efficiently working with both text and graphics on an OLED display; stay tuned for updates!

|

|

|

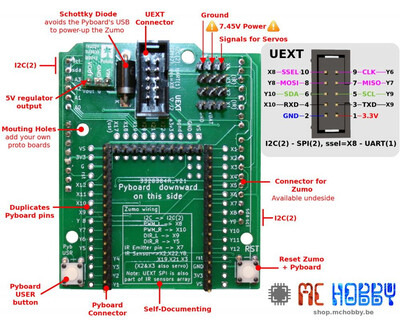

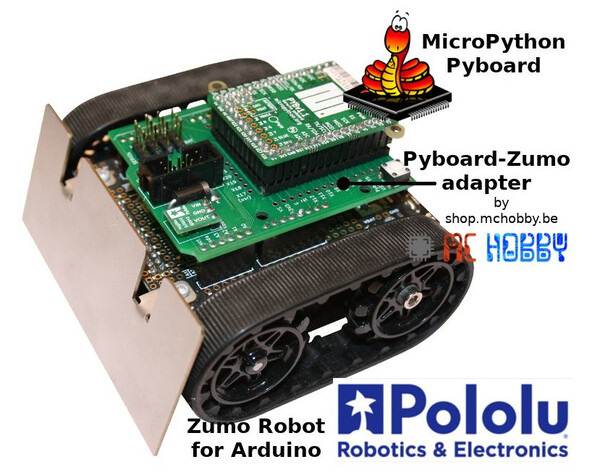

Zumo adapter for MicroPython Pyboard by MCHobby

|

Belgian distributor MCHobby has released an adapter that allows a MicroPython Pyboard to control a Zumo Robot for Arduino. Using their MicroPython port of our Zumo Shield library, you can run programs like this on the Zumo:

from zumoshield import ZumoShield zumo = ZumoShield() zumo.motors.setSpeeds( 100, 100 ) # -400..0..400 zumo.motors.stop()

Even cooler, the on-board REPL allows live programming/debugging over USB. Here’s an example from their library documentation that shows a test of the Zumo’s accelerometer:

MicroPython v1.16-92-g98c570302-dirty on 2021-07-16; PYBv1.1 with STM32F405RG Type "help()" for more information. >>> >>> import test_acc x -241 y -23 x -236 y -16 x -233 y -68 x -223 y -81 x 1110 y -7073 <--- Knocked on the right side x -309 y -35 x -242 y -69

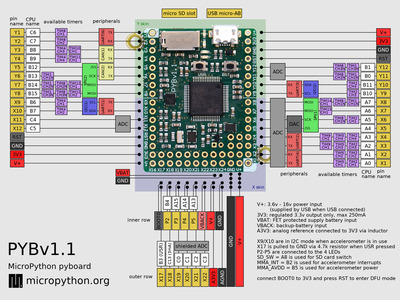

MicroPython is a minimal Python interpreter designed to run on microcontrollers such as the the Espressif ESP8266 and ESP32, the Raspberry Pi RP2040, and a variety of Arm processors. The Pyboard we are talking about here is the official reference board for MicroPython, based on a powerful Arm Cortex-M4 processor by ST. As you can see in the pinout diagrams below, most of the pins of the Pyboard are also broken out on the Zumo adapter, and the two Pyboard buttons are duplicated in more convenient locations:

|

|

An included Pololu voltage regulator and power diode allow the robot to be fully powered with batteries and also to safely connect to USB for programming. The MCHobby libraries demonstrate how to access all of the Zumo features from the Pyboard, in particular including example MicroPython code for line following and maze solving. There are many more possibilities with MicroPython on the Zumo, and we’re excited to see what the community will do with it!

For more information or to buy a board, see the Adaptateur Pyboard pour ZUMO Robot product page.

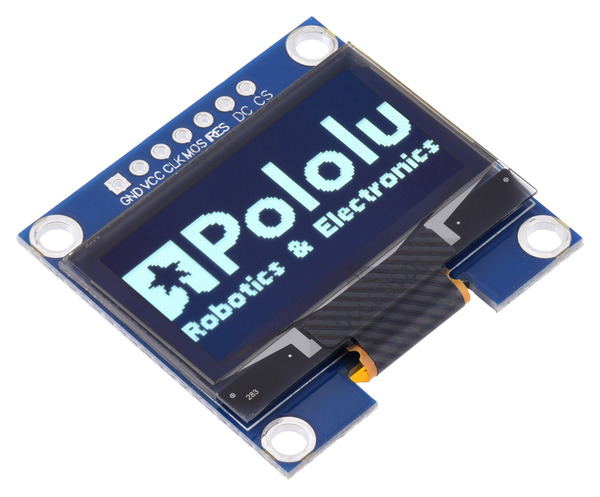

New product: 1.3" graphical OLED display

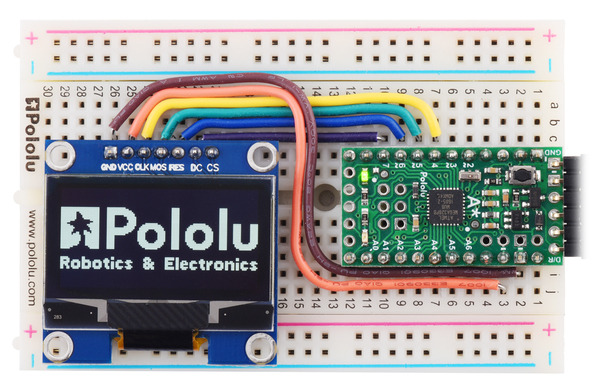

We’re now selling an OLED display module that you can use to add some fancy graphics to your project! This monochrome OLED screen measures 1.3 inches diagonally and uses a common SH1106 driver that can be controlled via SPI communication. (For more information, see its product page.)

|

Graphical OLED Display: 128×64, 1.3", White Pixels, SPI, Blue PCB, controlled by an A-Star 328PB Micro running at 3.3V. |

|---|

With a 128×64 grid of individually-controllable, high-contrast pixels, this OLED display can show a lot more information (and looks a lot cooler) than simple text-only LCD screens. We’re working on something that can take advantage of these enhanced graphical capabilities, so keep an eye out for updates!

Independence Day Sale going on now!

We are having an Independence Day sale starting now through Monday, July 5! Check out the sale page for more information. Please note that we will be closed Monday, so orders placed after 2 PM Pacific Time Friday, July 2 will be shipped on Tuesday, July 6.

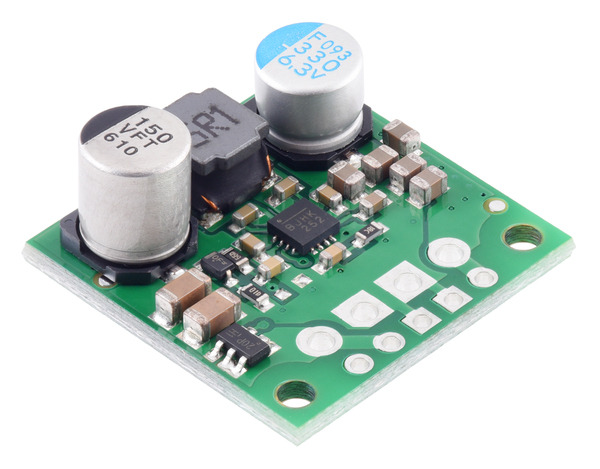

New product: 5V Step-Up/Step-Down Voltage Regulator S13V30F5

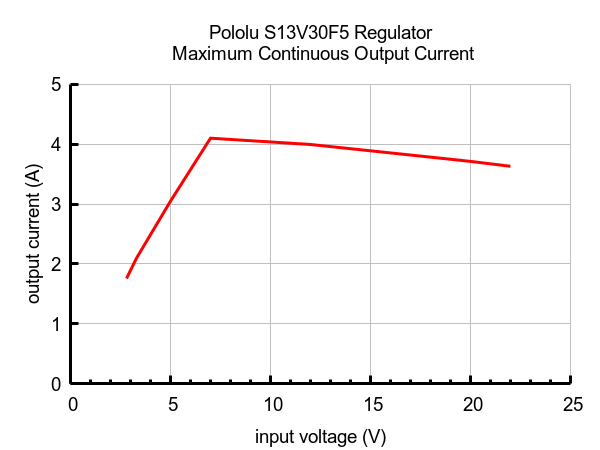

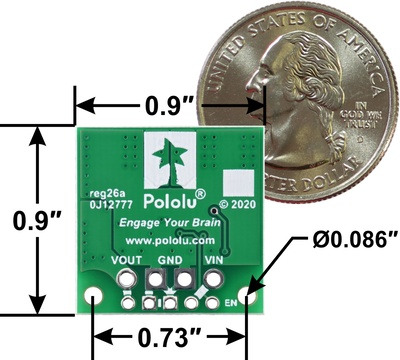

I started routing the PCB for the S13V30F5 5V step-up/step-down voltage regulator in January of 2020, and we were in the middle of testing the assembled prototypes when the pandemic shutdowns hit. Like lots of other things in 2020, the project got put on hold because appropriate testing requires a decent amount of equipment and is not the easiest thing to do remotely. That only makes it more exciting to announce that the S13V30F5, our most powerful step-up/step-down regulator, is now available! It operates from 2.8 V to 22 V and steps that voltage up or down as necessary to produce a fixed 5V output with typical efficiencies of 85% to 95%. As shown in the graph below, it can deliver around 3A continuously when the input is near 5V.

|

This new regulator measures just 0.9″ × 0.9″. That is almost half the size of our previously highest-power step-up/step-down units, the S18V20Fx family, which we have recently started rationing due to impacts from the global semiconductor shortages.

|

5V Step-Up/Step-Down Voltage Regulator S13V30F5, bottom view with dimensions. |

|---|

To help celebrate finally releasing the S13V30F5, we are offering an extra introductory special discount. The first hundred customers to use coupon code S13V30F5INTRO can get up to five units for just $9.95 each!

New high-speed linear actuators

We are excited to announce the addition of new GF23-series high-speed linear actuators to our already extensive linear actuator selection. This brand new Glideforce series from Concentric International is specifically designed for high-speed, light-duty applications, offering almost twice the speed of our previously fastest options while still supporting almost the same dynamic loads. This video demonstrates the speeds of the four types of light-duty actuators we carry:

They are available in 2″, 4″, 6″, 8″, 10″, and 12″ lengths with or without a feedback potentiometer. The table below shows how these new units compare to our other light-duty options, which are slower but stronger:

This brings our total selection of light-duty actuators to 48 options, and our total overall selection of linear actuators to 82 options, all stocked and available to ship the day you order.

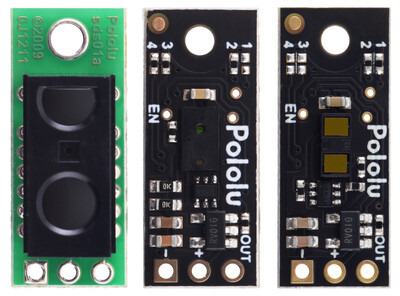

New longer-range Pololu distance sensors

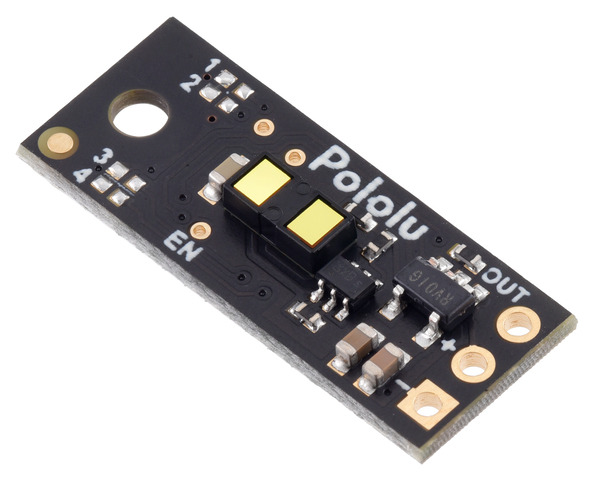

We released the first of our new Pololu distance sensors a few months ago, and now we’re releasing additional Pololu Digital Distance Sensors with longer ranges! These boards have the same form factor and pinout as both our old Sharp/Socle GP2Y0D8x carrier boards and the short-range Pololu distance sensors designed to replace those, but the new versions offer greatly increased detection and measurement ranges, opening up new possibilities in applications where longer-distance sensing capabilities are desired.

|

Comparison of a Pololu Carrier with Sharp GP2Y0D8x Digital Distance Sensor and two Pololu Digital Distance Sensors (irs16a and irs17a). |

|---|

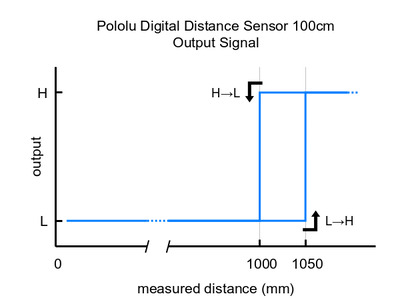

Like their shorter-range counterparts, these new Pololu distance sensors determine distance by using an integrated lidar module to measure the time of flight (ToF) of invisible, eye-safe infrared laser light. The new versions include four digital output versions, which simply indicate whether they detect an object within their respective range thresholds:

- Pololu Digital Distance Sensor 25cm

- Pololu Digital Distance Sensor 50cm

- Pololu Digital Distance Sensor 100cm

- Pololu Digital Distance Sensor 200cm

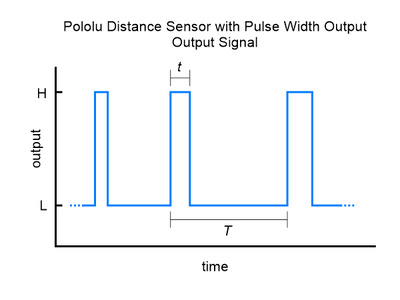

There are also two new versions with pulse width outputs, which encode a distance measurement in a pulsed signal:

- Pololu Distance Sensor with Pulse Width Output, 130cm Max

- Pololu Distance Sensor with Pulse Width Output, 300cm Max

(For more detail on how the different output types work, see the earlier announcement or the sensors’ product pages.)

|

|

This brings us up to ten different Pololu distance sensor options, as shown in these tables:

| Digital output (does not provide distance measurement) |

|||||

| Sensor | Maximum range1 |

Minimum range |

Minimum update rate |

Jumper settings (4321) |

PCB ID |

|---|---|---|---|---|---|

| #4050: Digital output, 5cm | 5 cm | < 5 mm | 145 Hz | 0000 | irs16a |

| #4052: Digital output, 10cm | 10 cm | < 5 mm | 115 Hz | 0010 | |

| #4054: Digital output, 15cm | 15 cm | < 5 mm | 95 Hz | 0100 | |

| #4066: Digital output, 25cm | 25 cm | < 1 mm | 100 Hz | 0000 | irs17a |

| #4067: Digital output, 50cm | 50 cm | < 1 mm | 100 Hz | 0001 | |

| #4069: Digital output, 100cm | 100 cm | < 1 mm | 100 Hz | 0011 | |

| #4077: Digital output, 200cm | 200 cm | < 1 mm | 30 Hz | 1011 | |

| Pulse width output (provides distance measurement) |

||||||

| Sensor | Maximum range1 |

Minimum range2 |

Resolution | Minimum update rate |

Jumper settings (4321) |

PCB ID |

|---|---|---|---|---|---|---|

| #4064: Pulse width output, 50cm max | ~50 cm | 1 cm | 3 mm | 50 Hz | 1110 | irs16a |

| #4071: Pulse width output, 130cm max | ~130 cm | 4 cm | 1 mm | 100 Hz | 0101 | irs17a |

| #4079: Pulse width output, 300cm max | ~300 cm | 4 cm | 2 mm | 30 Hz | 1101 | |

1 Effective range depends on object reflectivity and ambient lighting conditions.

2 Objects closer than the minimum distance can still be detected, but the measured distance might be inaccurate. The minimum detection range is < 5 mm for irs16a boards and < 1 mm for irs17a boards.

We’ve also just published comprehensive information about all the possible jumper settings for these sensor boards on their respective product pages. By changing the jumper connections, you can make a sensor act like a different version or even select another configuration that isn’t available as a standard product. (And if you have a special volume requirement, we can manufacture a custom batch of sensors for you; please contact us for more information.)

Once again, we are offering an extra introductory special discount on these sensors, to help share in our celebration of releasing new products. The first hundred customers to use coupon code DISTSENSORS can get up to three units of each type (including the shorter-ranged versions released earlier) for just $9.95 each!

Memorial Day Sale going on now!

We are having a Memorial Day sale all weekend long with site-wide discounts of up to 25%! Check out the sale page for more information. Please note that we will be closed Monday, so orders placed after 2 PM Pacific Time Friday, May 28 will be shipped on Tuesday, June 1.

Video from content creator Curio Res: How to control a DC motor with encoder

Content creator Curio Res recently released a tutorial and accompanying video explaining how to control a DC motor with an encoder. The video and post cover how to set up a motor with encoder, a controller, and a motor driver and how to read encoder signals. They also address common questions we get from customers who want to add closed-loop feedback to their projects such as how to implement a PID algorithm to control the position of the motor shaft based on the encoder readings. The content is well explained, and the diagrams and motion graphics make everything easy to follow and understand.

The tutorial uses one of our 37D Metal Gearmotors and our TB67H420FTG Motor Driver Carrier. The tutorial also uses an Arduino Uno, but one of our A-Star 32U4 Primes could be used instead.

If you like Curio Res’s content, be sure to subscribe to their YouTube channel so you don’t miss their latest videos. We look forward to seeing more great tutorials from Curio Res!

20th Anniversay Sale

We are having a sale to celebrate our 20th anniversary! Get 20% off 20 big categories of products! The sale runs until the end of April. Visit the sale page for details!