Pololu Blog »

New products: Micro Metal Gearmotors with integrated encoders

|

|

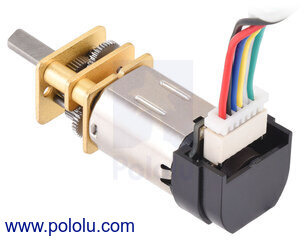

Our Micro Metal Gearmotors are now available with integrated quadrature encoders! These are the same top-entry and side-entry encoders that were previously only available separately, and now you can get them preassembled on the gearmotors and covered by a snap-on plastic cap. On the assembled units, the two available styles are denoted as “Back Connector”, which has the connector oriented parallel to the motor, and “Side Connector”, which is perpendicular to the motor. These connectors work with our assortment of female 6-pin JST SH-style cables and 6-pin JST SH-style connector boards.

|

|

For detailed dimensions, specifications, and usage information, see the Micro Metal Gearmotor datasheet (5MB pdf).

With 65 different combinations of gearboxes and motors each now available with two encoder styles, that makes 130 new products in all, and it increases our total Micro Metal Gearmotor selection to 260 versions. We are still working on getting everything stocked up, but we manufacture these in house, so we can make some of any particular version quickly. If there is a version you want that is currently out of stock, you can backorder it and we should be able to make and ship it in a few days. (Please note that we are currently not stocking the 5:1 versions with encoders but we are able to make them by special request; please contact us if you are interested in placing a special order for those.) Here is a full list of all the available options now:

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder |

w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| HPCB 12V (high-power, carbon brushes) |

|||||||||||

| 12 V | 0.75 A | 100 mA | 6800 | 0.09 | 1.3 | – | 5:1 | #3036 | #3047 | #5204 | #5205 |

| 80 mA | 3400 | 0.17 | 2.4 | 1.5 | 10:1 | #3037 | #3048 | #5206 | #5207 | ||

| 2200 | 0.25 | 3.5 | 1.4 | 15:1 | #4788 | #4789 | #5208 | #5209 | |||

| 1100 | 0.39 | 5.4 | 1.1 | 30:1 | #3038 | #3049 | #5210 | #5211 | |||

| 650 | 0.67 | 9.3 | 1.1 | 50:1 | #3039 | #3050 | #5212 | #5213 | |||

| 450 | 1.0 | 14 | 1.1 | 75:1 | #3040 | #3051 | #5214 | #5215 | |||

| 330 | 1.3 | 18 | 1.1 | 100:1 | #3041 | #3052 | #5216 | #5217 | |||

| 220 | 1.8 | 25 | 1.0 | 150:1 | #3042 | #3053 | #5218 | #5219 | |||

| 160 | 2.5 | 35 | 1.0 | 210:1 | #3043 | #3054 | #5220 | #5221 | |||

| 130 | 3.0 | 42 | 1.1 | 250:1 | #3044 | #3055 | #5222 | #5223 | |||

| 110 | 3.3 | 46 | 1.0 | 298:1 | #3045 | #3056 | #5224 | #5225 | |||

| 85 | 5.0 | 69 | 1.1 | 380:1 | #4798 | #4799 | #5226 | #5227 | |||

| 35 | 10 | 140 | – | 1000:1 | #3046 | #3057 | #5228 | #5229 | |||

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder | w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| HPCB 6V (high-power, carbon brushes) |

|||||||||||

| 6 V | 1.5 A | 170 mA | 6500 | 0.09 | 1.3 | – | 5:1 | #3060 | #3082 | #5178 | #5179 |

| 150 mA | 3300 | 0.17 | 2.4 | 1.3 | 10:1 | #3061 | #3071 | #5180 | #5181 | ||

| 2100 | 0.25 | 3.5 | 1.3 | 15:1 | #4786 | #4787 | #5182 | #5183 | |||

| 1100 | 0.45 | 6.2 | 1.2 | 30:1 | #3062 | #3072 | #5184 | #5185 | |||

| 650 | 0.74 | 10 | 1.2 | 50:1 | #3063 | #3073 | #5186 | #5187 | |||

| 430 | 1.1 | 15 | 1.3 | 75:1 | #3064 | #3074 | #5188 | #5189 | |||

| 330 | 1.6 | 22 | 1.3 | 100:1 | #3065 | #3075 | #5190 | #5191 | |||

| 220 | 2.0 | 28 | 1.1 | 150:1 | #3066 | #3076 | #5192 | #5193 | |||

| 160 | 2.8 | 39 | 1.1 | 210:1 | #3067 | #3077 | #5194 | #5195 | |||

| 130 | 3.2 | 44 | 1.1 | 250:1 | #3068 | #3078 | #5196 | #5197 | |||

| 110 | 3.4 | 47 | 1.0 | 298:1 | #3069 | #3079 | #5198 | #5199 | |||

| 85 | 5.0 | 69 | 1.1 | 380:1 | #4796 | #4797 | #5200 | #5201 | |||

| 33 | 11 | 150 | – | 1000:1 | #3070 | #3080 | #5202 | #5203 | |||

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder | w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| HP 6V (high-power) |

|||||||||||

| 6 V | 1.6 A | 120 mA | 6100 | 0.11 | 1.5 | – | 5:1 | #1000 | #2210 | #5152 | #5153 |

| 100 mA | 3100 | 0.22 | 3.0 | 1.6 | 10:1 | #999 | #2211 | #5154 | #5155 | ||

| 2000 | 0.30 | 4.2 | 1.5 | 15:1 | #4784 | #4785 | #5156 | #5157 | |||

| 1000 | 0.57 | 7.9 | 1.5 | 30:1 | #1093 | #2212 | #5158 | #5159 | |||

| 590 | 0.86 | 12 | 1.3 | 50:1 | #998 | #2213 | #5160 | #5161 | |||

| 410 | 1.3 | 18 | 1.4 | 75:1 | #2361 | #2215 | #5162 | #5163 | |||

| 310 | 1.7 | 24 | 1.3 | 100:1 | #1101 | #2214 | #5164 | #5165 | |||

| 210 | 2.4 | 33 | 1.2 | 150:1 | #997 | #2386 | #5166 | #5167 | |||

| 150 | 3.0 | 42 | 1.1 | 210:1 | #996 | #2216 | #5168 | #5169 | |||

| 120 | 3.4 | 47 | 1.1 | 250:1 | #995 | #2217 | #5170 | #5171 | |||

| 100 | 4.0 | 56 | 1.1 | 298:1 | #994 | #2218 | #5172 | #5173 | |||

| 84 | 5.5 | 76 | 1.1 | 380:1 | #4794 | #4795 | #5174 | #5175 | |||

| 31 | 12 | 170 | – | 1000:1 | #1595 | #2373 | #5176 | #5177 | |||

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder | w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| MP 6V (medium-power) |

|||||||||||

| 6 V | 0.67 A | 80 mA | 4400 | 0.06 | 0.8 | – | 5:1 | #2362 | #2376 | #5126 | #5127 |

| 70 mA | 2200 | 0.11 | 1.5 | – | 10:1 | #2363 | #2377 | #5128 | #5129 | ||

| 1400 | 0.20 | 2.8 | 0.70 | 15:1 | #4782 | #4783 | #5130 | #5131 | |||

| 720 | 0.33 | 4.6 | 0.57 | 30:1 | #2364 | #2378 | #5132 | #5133 | |||

| 420 | 0.54 | 7.5 | 0.55 | 50:1 | #2365 | #2379 | #5134 | #5135 | |||

| 290 | 0.78 | 11 | 0.54 | 75:1 | #2366 | #2380 | #5136 | #5137 | |||

| 220 | 0.94 | 13 | 0.50 | 100:1 | #2367 | #2381 | #5138 | #5139 | |||

| 150 | 1.3 | 18 | 0.48 | 150:1 | #2368 | #2382 | #5140 | #5141 | |||

| 100 | 1.7 | 24 | 0.46 | 210:1 | #2369 | #2383 | #5142 | #5143 | |||

| 88 | 2.2 | 31 | 0.48 | 250:1 | #2370 | #2384 | #5144 | #5145 | |||

| 73 | 2.4 | 33 | 0.44 | 298:1 | #2371 | #2385 | #5146 | #5147 | |||

| 57 | 3.6 | 50 | 0.53 | 380:1 | #4792 | #4793 | #5148 | #5149 | |||

| 22 | 6.7 | 93 | – | 1000:1 | #2372 | #3059 | #5150 | #5151 | |||

| Rated Voltage |

Stall Current |

No-Load Current |

No-Load Speed (RPM) |

Extrapolated Stall Torque |

Max Power (W) |

Approx Gear Ratio |

No Encoder | w/ Extended Motor Shaft |

w/ Encoder, Back Conn. |

w/ Encoder, Side Conn. |

|

| (kg⋅cm) | (oz⋅in) | ||||||||||

| LP 6V (low-power) |

|||||||||||

| 6 V | 0.36 A | 50 mA | 2500 | 0.05 | 0.7 | – | 5:1 | #1100 | #2200 | #5100 | #5101 |

| 40 mA | 1300 | 0.10 | 1.4 | – | 10:1 | #1099 | #2201 | #5102 | #5103 | ||

| 860 | 0.17 | 2.4 | 0.37 | 15:1 | #4780 | #4781 | #5104 | #5105 | |||

| 450 | 0.29 | 4.0 | 0.31 | 30:1 | #993 | #2202 | #5106 | #5107 | |||

| 270 | 0.44 | 6.1 | 0.29 | 50:1 | #1098 | #2203 | #5108 | #5109 | |||

| 180 | 0.64 | 8.9 | 0.29 | 75:1 | #2360 | #2209 | #5110 | #5111 | |||

| 130 | 0.74 | 10 | 0.25 | 100:1 | #992 | #2204 | #5112 | #5113 | |||

| 90 | 1.1 | 15 | 0.25 | 150:1 | #1097 | #2205 | #5114 | #5115 | |||

| 65 | 1.6 | 22 | 0.25 | 210:1 | #1096 | #2206 | #5116 | #5117 | |||

| 54 | 1.7 | 24 | 0.23 | 250:1 | #1095 | #2207 | #5118 | #5119 | |||

| 45 | 2.0 | 28 | 0.22 | 298:1 | #1094 | #2208 | #5120 | #5121 | |||

| 36 | 2.9 | 40 | 0.27 | 380:1 | #4790 | #4791 | #5122 | #5123 | |||

| 13 | 5.5 | 76 | – | 1000:1 | #1596 | #3058 | #5124 | #5125 | |||

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. The recommended upper limit for instantaneous torque is 2.5 kg⋅cm (35 oz⋅in) for the 380:1 and 1000:1 gearboxes, and 2 kg⋅cm (25 oz⋅in) for all the other gear ratios; we strongly advise keeping applied loads well under this limit. Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes, especially for the versions that use high-power (HP and HPCB) motors; a general recommendation for brushed DC motor operation is 25% or less of the stall current.