Pololu Blog » Posts tagged “new products” »

Posts tagged “new products” (Page 14)

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

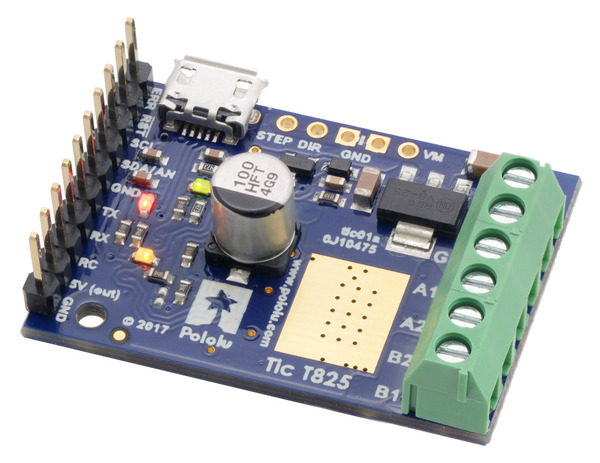

Introducing the Tic T825 USB Multi-Interface Stepper Motor Controller

I am excited to announce our new product, the Tic T825 USB Multi-Interface Stepper Motor Controller. The Tic makes basic speed or position control of a stepper motor easy, with support for six high-level control interfaces:

- USB for direct connection to a computer

- TTL serial operating at 5 V for use with a microcontroller

- I²C for use with a microcontroller

- RC hobby servo pulses for use in an RC system

- Analog voltage for use with a potentiometer or analog joystick

- Quadrature encoder input for use with a rotary encoder dial, allowing full rotation without limits (not for position feedback)

You can select which of these interfaces you want to use and configure the other settings of the Tic over USB using our free software.

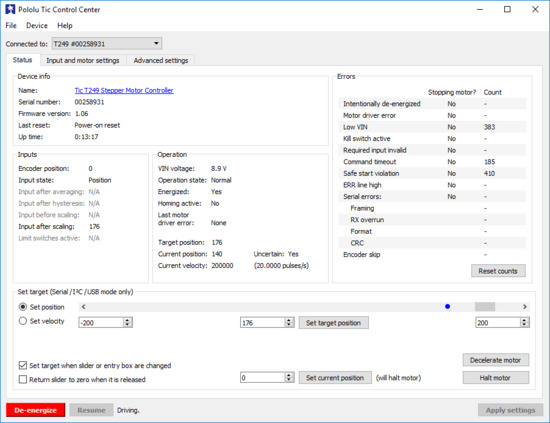

|

The Status tab of the Pololu Tic Control Center. |

|---|

|

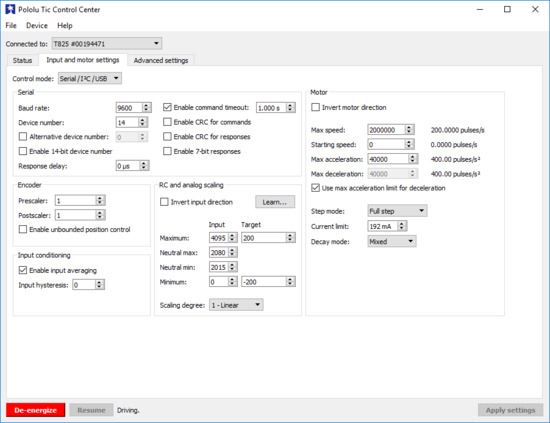

The Input and Motor Settings tab of the Pololu Tic Control Center. |

|---|

The Tic T825 can operate from 8.5 V to 45 V and deliver up to approximately 1.5 A per phase continuously without a heat sink or forced air flow. With a digitally adjustable current limit that can be set over USB, serial, or I²C, you can save power while holding position or increase the motor’s torque while it is moving. The Tic offers six different step resolutions, from full step through 1/32-step (32 microsteps per full step). We designed the Tic’s firmware to be capable of taking up to 50,000 microsteps per second, which lets you use those finer microstepping modes while still keeping a high motor speed. The Tic also supports acceleration and deceleration limiting for smooth movements, and very slow speeds down to 1 step every 200 seconds (or 1 step every 1428 seconds with reduced resolution). The Tic T825 is based on the DRV8825 stepper motor driver IC from Texas Instruments (for which we also have a basic carrier board), and we plan to make other versions of the Tic that are based on different drivers with different performance characteristics.

|

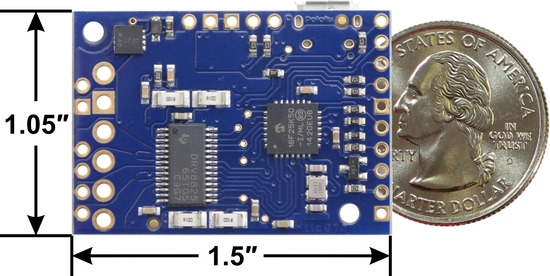

Tic T825 USB Multi-Interface Stepper Motor Controller, bottom view with dimensions. |

|---|

The Tic T825 is available with connectors soldered in or without connectors soldered in.

For RC/hobby servos, we have a similar family of products called the Maestro servo controllers. For brushed DC motors, we offer the Simple Motor Controllers and the Jrk Motor Controllers.

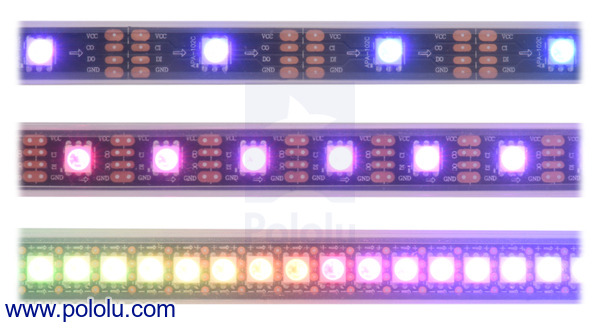

New SK9822 LED strips and panels

We’re excited to offer a series of addressable LED strips and addressable LED panels based on the new SK9822 integrated circuit. Like the APA102C, the SK9822 combines an RGB LED and driver into a single 5050-size package, allowing each pixel to be individually controlled using a simple two-wire SPI protocol.

The SK9822 is almost (see the notes below) a drop-in replacement for the APA102C and is better than it in a few ways, most importantly its built-in constant current control. If you’ve ever tried to power a long chain of LED strips and only connected power at one end, you might have noticed that the far end of the LED strip has a lower voltage across its power rails because of resistance in the long power connections. For LED strips based on the APA102C and WS2812B, the lower voltage makes the light dimmer and redder. With the SK9822, voltage drops like that are less likely to have a visible effect as long as the voltage stays above 3.5 V.

The SK9822’s protocol is very similar to that of the APA102C, but it updates the color that is being shown at a different time. If you replace APA102C LEDs with SK9822 LEDs in a low frame-rate application, you might have to update the code you are using to control the LEDs. The latest version of our APA102 Arduino library works with the SK9822 so you can either use it directly or use it as a reference when writing your own code. The colors generated by the SK9822 look different from the colors generated by the APA102C, so we would not recommend mixing the APA102C and the SK9822 in a single project.

We offer six different kinds of SK9822 LED strip with different LED densities and lengths:

- 1 meter, 30 LEDs (30 LEDs/m)

- 2 meters, 60 LEDs (30 LEDs/m)

- 5 meters, 150 LEDs (30 LEDs/m)

- 1 meter, 60 LEDs (60 LEDs/m)

- 2 meters, 120 LEDs (60 LEDs/m)

- 0.5 meters, 72 LEDs (144 LEDs/m)

We offer SK9822 LED panels in three different sizes:

These new SK9822-based products will replace our older APA102C-based products.

We continue to offer SK6812-based LED strips which also have constant current control but are controlled with a one-wire protocol.

|

Close up of an SK9822, with the red, green, and blue LEDs on at a low brightness. |

|---|

|

An addressable RGB LED strip (APA102C or SK9822) displaying a rainbow animation. |

|---|

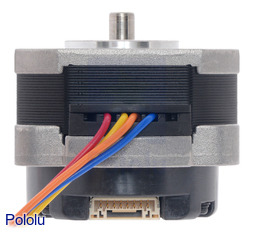

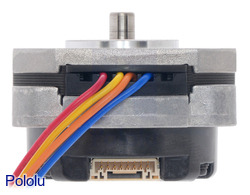

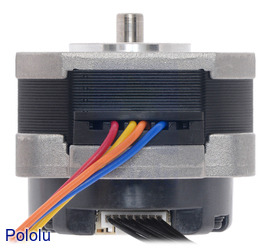

Sanyo pancake stepper motors with encoders

We are now offering two new NEMA 17-size pancake bipolar stepper motors from Sanyo, each featuring an integrated high-resolution quadrature encoder and home channel for absolute positioning.

| Stepper motor | Steps per revolution | Current rating (per coil) | Voltage rating | Resistance (per coil) | Holding torque |

|---|---|---|---|---|---|

| #2279 42×31.5mm | 200 | 1 A | 5.4 V | 5.4 Ω | 1.9 kg-cm (26 oz-in) |

| #2278 42×24.5mm | 200 | 1 A | 3.5 V | 3.5 Ω | 800 g-cm (12 oz-in) |

|

|

The integrated quadrature encoder operates from 5 V and has a resolution of 1000 P/R, which allows for 4000 counts per revolution (CPR) of the output shaft when counting both edges (i.e. rising and falling) of both channels (i.e. A and B). In addition to the A and B channel outputs, the encoder has a home channel, Z, that pulses once per revolution and can be used for absolute positioning. The encoder also has outputs for the inverse of A, B, and Z. A 15 cm (6″) encoder cable is included.

|

|

|

New 12V 1A wall power adapter

We’ve replaced our original 12 V 1 A wall power adapter with a lighter, smaller version. This UL-listed 12 W, “wall wart”-style switching power adapter supplies up to 1 A at a regulated 12 VDC. The AC adapter works with input voltages of 100 to 240 VAC and has a 1.5 m (5 ft) DC power cord that is terminated by a center-positive, 5.5 × 2.1 mm barrel connector.

Free Circuit Cellar magazine April 2017

|

Get a FREE copy of Circuit Cellar magazine’s April 2017 issue issue with your order, while supplies last. To get your free issue, enter the coupon code CIRCUIT0417 to your shopping cart, or click the link. The magazine will add 6 ounces to your order weight when calculating your shipping options.

For back issues and more information, see our free Circuit Cellar magazine offers.

FEETECH Mini Servo FT1117M

We added the FEETECH Mini Servo FT1117M to our expanding RC servo selection.This miniature-sized servo has a stall torque of 50 oz-in (3.5 kg-cm) and a speed of 0.11 sec/60° at 6 V. The pinion gear is plastic, but the rest of the gear train consists of all metal gears, allowing this servo to deliver the kind of speed and torque typically associated with larger servos.

Comparison to the Power HD 1711MG mini servo

This servo is a lower-cost alternative to the 1711MG from Power HD, which has nearly identical dimensions and performance. The two servos should be generally interchangeable for most applications. The picture below shows both the FT1117M and the 1711MG side by side:

|

Expect more new FEETECH servos in the coming weeks!

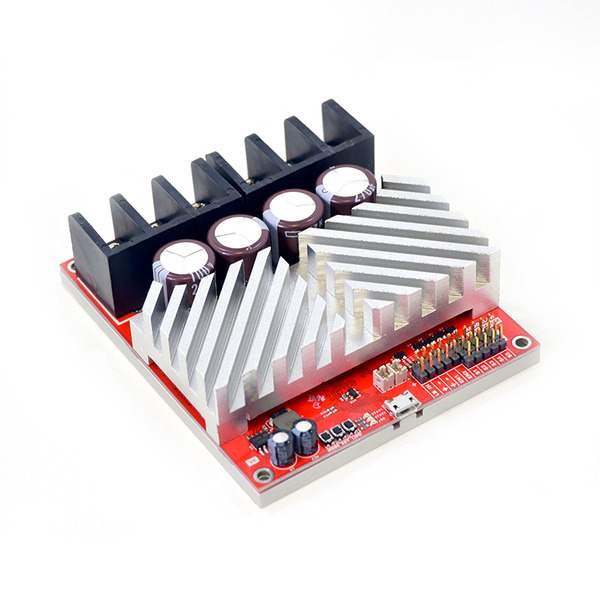

RoboClaw 2x60A Motor Controller (V6)

|

The RoboClaw 2x60A motor controller (V5) we’ve been carrying has been replaced by the new RoboClaw 2x60A Motor Controller (V6). This powerful motor controller can drive two brushed DC motors with 60 A continuously at voltages from 6 V to 34 V, and it allows for peak currents up to 120 A. Version six adds a protective aluminum plate to the board bottom and ports for connecting optional cooling fans that are controlled based on the board temperature.

|

RoboClaw 2×60A Motor Controller (V6) and RoboClaw 2×60AHV Motor Controller (60VDC), bottom view. |

|---|

The RoboClaw motor controllers from Ion Motion Control can control a pair of brushed DC motors using USB serial, TTL serial, RC, or analog inputs. Integrated dual quadrature decoders make it easy to create a closed-loop speed control system, or analog feedback can be used for position control.

For more information, see the product page.

Wall Power Adapter: 5.25VDC, 2.4A, 20AWG MicroUSB Cable

We’ve added this Micro-USB wall adapter to our catalog. It can supply up to 2.4 A at 5.25 VDC (the USB specification’s maximum bus voltage), allowing for voltage drop due to power draw when powering 5 V electronics. It features a 1.5 m to 1.8 m (5 ft to 6 ft) DC power cord with 20 AWG wires that is terminated by a USB Micro-B connector, which makes it great for powering devices like a Raspberry Pi (especially newer Raspberry Pi models, like the Pi 3, which can draw a lot of current!).

|

Raspberry Pi connected to a Wall Power Adapter: 5.25VDC, 2.5A, 20AWG MicroUSB Cable. |

|---|

For more details, see the product page.

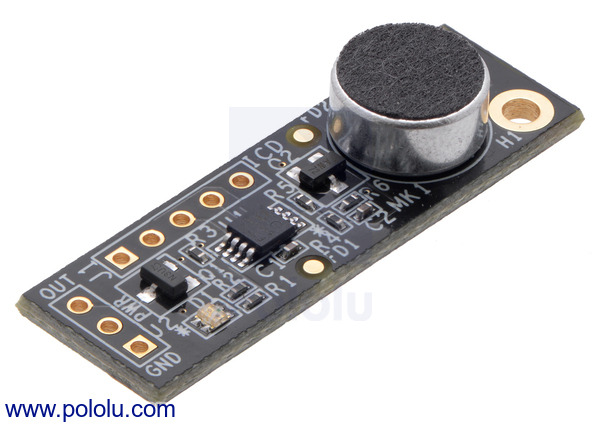

Verbal Machines VM-CLAP1 Hand Clap Sensor

Don’t hold your applause: we are now offering the Verbal Machines VM-CLAP1 Hand Clap Sensor! This board is a low-power, microprocessor-based audio sensor that can detect hand claps or finger snaps while ignoring background noises such as human speech or music. It operates from 2.5 V to 5.5 V and offers a simple interface: when a clap or snap is detected, the output pin goes low for 40 ms, and the integrated blue LED lights up.

|

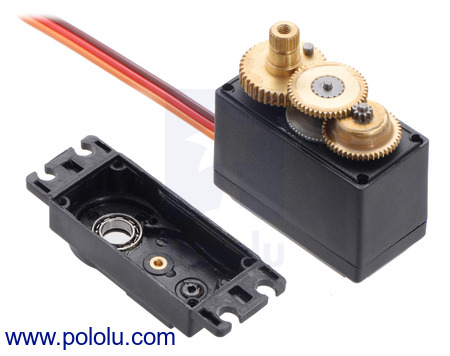

FEETECH High-Torque Servo FS5115M

We added the FEETECH High-Torque Servo FS5115M to our expanding RC servo selection. This standard-size analog servo has a stall torque of 215 oz-in (15.5 kg-cm) at 6 V, more than twice the torque of our standard-size servos with plastic gears thanks to its powerful motor and all-metal gear train. This higher torque requires more power: this servo can draw bursts of current in excess of 3 A at 6 V, about three times higher than a typical standard-size servo. The output shaft is supported by two ball bearings for reduced friction.

|

Comparison to the Power HD 1501MG high-torque servo

This servo is a lower-cost alternative to the 1501MG from Power HD, which has nearly identical dimensions and similar performance. The two servos should be generally interchangeable for most applications. The picture below shows both the FS5115M and the 1501MG side by side:

|

Expect more new FEETECH servos in the coming weeks!