Pololu Blog » User Profile: Ben » Posts by Ben »

Posts by Ben (Page 10)

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

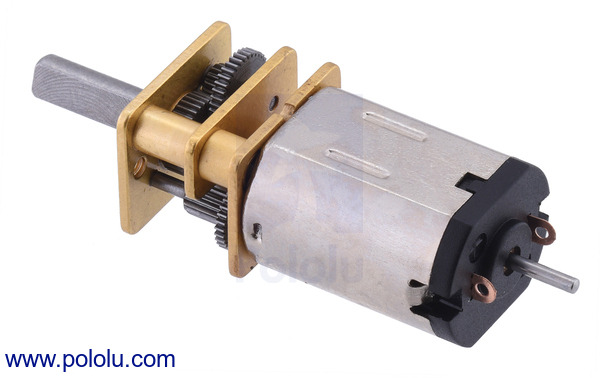

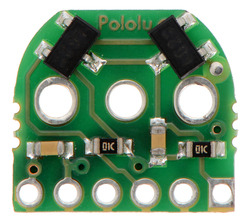

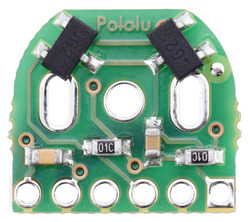

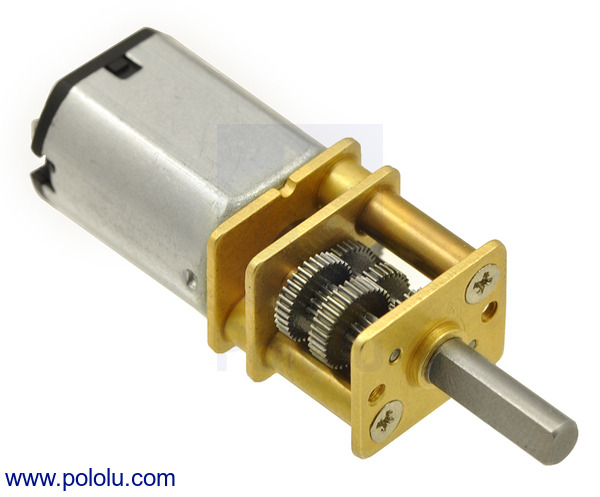

HPCB micro metal gearmotors with extended motor shafts

It has been a few months since we introduced our new high-power micro metal gearmotors with longer life carbon brushes. We now have them available with dual shafts, and we have made a corresponding update to our magnetic encoders to let them work with the larger terminals of the HPCB motors.

|

|

|

You might see similar-looking motors elsewhere, but no one comes close to our offering, from the quality of the gears to the variety of winding options to the selection of gear ratios, all in stock for shipment the day you order. By bringing together Pololu’s exclusive features of high-power windings, long-life carbon brushes, and encoders for closed-loop feedback control into a single package, these latest motors and encoders really demonstrate our continual investment in this popular form factor. With ten gear ratios available, from 10:1 through 1000:1, our total selection of micro metal gearmotors has grown to nearly 70 options:

| Motor Type | Stall Current @ 6 V |

No-Load Speed @ 6 V |

Approximate Stall Torque @ 6 V |

Single-Shaft (Gearbox Only) |

Dual-Shaft (Gearbox & Motor) |

|---|---|---|---|---|---|

| high-power, carbon brushes (HPCB) |

1600 mA | 3000 RPM | 4 oz-in | 10:1 HPCB | 10:1 HPCB dual-shaft |

| 1000 RPM | 9 oz-in | 30:1 HPCB | 30:1 HPCB dual-shaft | ||

| 625 RPM | 15 oz-in | 50:1 HPCB | 50:1 HPCB dual-shaft | ||

| 400 RPM | 22 oz-in | 75:1 HPCB | 75:1 HPCB dual-shaft | ||

| 320 RPM | 30 oz-in | 100:1 HPCB | 100:1 HPCB dual-shaft | ||

| 200 RPM | 40 oz-in | 150:1 HPCB | 150:1 HPCB dual-shaft | ||

| 140 RPM | 50 oz-in | 210:1 HPCB | 210:1 HPCB dual-shaft | ||

| 120 RPM | 60 oz-in | 250:1 HPCB | 250:1 HPCB dual-shaft | ||

| 100 RPM | 70 oz-in | 298:1 HPCB | 298:1 HPCB dual-shaft | ||

| 32 RPM | 125 oz-in | 1000:1 HPCB | 1000:1 HPCB dual-shaft | ||

| high-power (HP) (same specs as HPCB above) |

1600 mA | 6000 RPM | 2 oz-in | 5:1 HP | |

| 3000 RPM | 4 oz-in | 10:1 HP | 10:1 HP dual-shaft | ||

| 1000 RPM | 9 oz-in | 30:1 HP | 30:1 HP dual-shaft | ||

| 625 RPM | 15 oz-in | 50:1 HP | 50:1 HP dual-shaft | ||

| 400 RPM | 22 oz-in | 75:1 HP | 75:1 HP dual-shaft | ||

| 320 RPM | 30 oz-in | 100:1 HP | 100:1 HP dual-shaft | ||

| 200 RPM | 40 oz-in | 150:1 HP | 150:1 HP dual-shaft | ||

| 140 RPM | 50 oz-in | 210:1 HP | |||

| 120 RPM | 60 oz-in | 250:1 HP | |||

| 100 RPM | 70 oz-in | 298:1 HP | 298:1 HP dual-shaft | ||

| 32 RPM | 125 oz-in | 1000:1 HP | 1000:1 HP dual-shaft | ||

| medium-power (MP) |

700 mA | 2200 RPM | 3 oz-in | 10:1 MP | 10:1 MP dual-shaft |

| 730 RPM | 8 oz-in | 30:1 MP | |||

| 420 RPM | 13 oz-in | 50:1 MP | |||

| 290 RPM | 17 oz-in | 75:1 MP | 75:1 MP dual-shaft | ||

| 220 RPM | 19 oz-in | 100:1 MP | 100:1 MP dual-shaft | ||

| 150 RPM | 24 oz-in | 150:1 MP | |||

| 75 RPM | 46 oz-in | 298:1 MP | |||

| 25 RPM | 80 oz-in | 1000:1 MP | 1000:1 MP dual-shaft | ||

| low-power | 360 mA | 2500 RPM | 1 oz-in | 5:1 | |

| 1300 RPM | 2 oz-in | 10:1 | |||

| 440 RPM | 4 oz-in | 30:1 | 30:1 dual-shaft | ||

| 250 RPM | 7 oz-in | 50:1 | 50:1 dual-shaft | ||

| 170 RPM | 9 oz-in | 75:1 | |||

| 120 RPM | 12 oz-in | 100:1 | 100:1 dual-shaft | ||

| 85 RPM | 17 oz-in | 150:1 | |||

| 60 RPM | 27 oz-in | 210:1 | |||

| 50 RPM | 32 oz-in | 250:1 | |||

| 45 RPM | 40 oz-in | 298:1 | 298:1 dual-shaft | ||

| 14 RPM | 70 oz-in | 1000:1 | 1000:1 dual-shaft |

You can see all ten of the new versions below, and if there are any versions we do not yet have that you would like to see us carry, let us know in the comments!

Polo-BOO! Halloween Sale

Halloween is just around the corner, but there is still time for you makers out there to build terrifying interactive props and amazing costumes, and we want to help. From now through October 21, we are having a sale on servos and servo controllers, proximity sensors, programmable microcontroller boards, power supplies, and more – all the products you might want to bring your creepy creations to life. See the sale page for more details and the full list of products.

If you need some inspiration, check out our sample Halloween projects, and as always, we would love to hear about anything cool you make with our products; we might feature it on the blog!

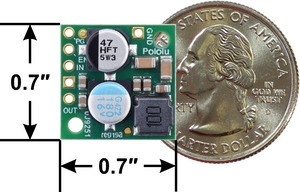

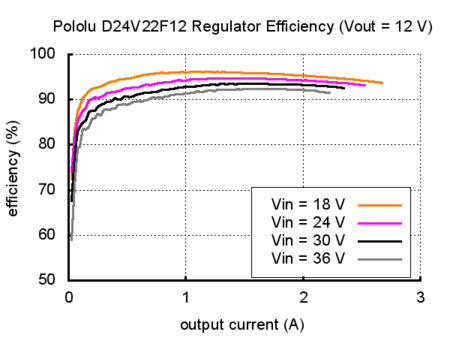

New product: 12V, 2.2A Step-Down Voltage Regulator D24V22F12

We are pleased to introduce our new 12 V, 2.2 A switching regulator, the inaugural member of the D24V22Fx family of step down voltage regulators. We expect to release other voltage versions next month, but we wanted to get a 12 V version out right away since we did not offer a 12 V buck regulator that could do more than 1 A. The compact regulator works with input voltages up to 36 V and can typically deliver up to a continuous 2.2 A. It offers integrated reverse voltage protection along with over-current and over-temperature shutoff, and a power-good output can be used to determine when the regulator cannot maintain its output voltage.

|

|

|

Unlike linear regulators which waste a lot of power and generate a lot of heat in the process, this new regulator is very efficient, which means you can get the most out of your battery life:

|

Until we release other voltage versions of the D24V22Fx, the closest substitutes are the similar D24V25Fx family of step-down voltage regulators:

These regulators are the same size as the D24V22F12 and they have similar current capabilities and input voltage ranges, but they do not have the same pinout and they are based on a different internal design, so there are fundamental differences in operation.

See the D24V22F12 product page for more information on this new regulator, or visit our voltage regulator category to see all of our regulator options.

New product: Pololu Ball Caster with 1″ Plastic Ball and Ball Bearings

|

|

Our ball caster with 1″ plastic ball is now available with ball bearings instead of plastic rollers for even better performance!

New Pololu 60×8mm wheels for FEETECH FS90R micro servos

Continuous rotation servos like FEETECH’s FS90R are popular actuators for beginner robots because of their low cost and ease of use—since the motor controller is built right into the actuator, it can be controlled directly from a microcontroller or RC receiver. However, to complete the drive system, you need wheels, and that is something that we have not been able to offer for the FS90R until today. I am excited to introduce the new 60×8mm wheels for FS90R micro servos, which should make it much easier to get your FS90R-based miniature robot rolling.

|

|

All that said, we still generally recommend creating custom drive systems out of individual motor drivers, DC motors, and wheels over continuous rotations servos, since that gives you much more control over performance. Continuous rotation servos are more appropriate for projects where cost and simplicity are more important than performance, and with these wheels and the FS90R, this approach is simpler and more affordable than ever.

Pololu Labor Day weekend sale

We are having a big Labor Day sale throughout the weekend, with 15% discounts on over 700 products when you use the coupon code LABORDAY15. Note that we will be closed on Monday, so orders placed after 2 PM Pacific Time on Friday, September 4 will be shipped on Tuesday, September 8.

For more information, including all of the sale items, see the sale page.

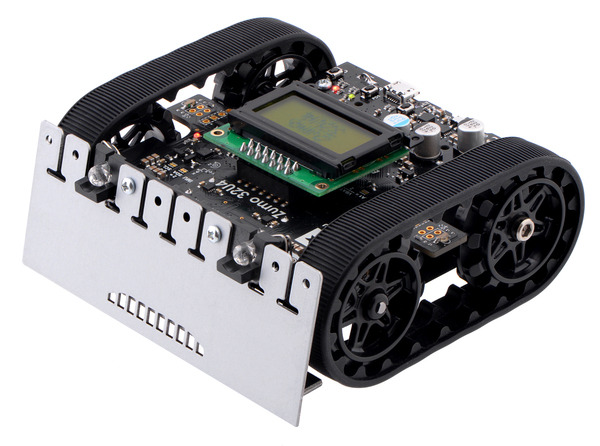

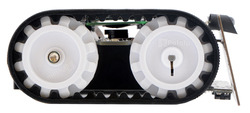

New products: Assembled Zumo 32U4 robots

Customers have been requesting an assembled version of our Zumo 32U4 robot kit ever since we released it in March, so it makes me very happy to be able to announce that we now have three pre-assembled Zumo 32U4 robots to choose from:

The three options differ only in their motors, and while the speed and torque vary across the three gear ratios, the peak output power is the same for all of them. You could maximize speed (i.e. 50:1 motors) or torque (100:1 motors), or perhaps you are looking for something in the middle (75:1 motors). The following table compares the gear ratio in more detail, with the first four columns showing specifications of the gearmotors by themselves and the last showing the measured top speed of a Zumo chassis loaded to a weight of 500 g:

| Micro Metal Gearmotor |

Free-Run Speed @ 6V |

Stall Torque @ 6V |

Stall Current @ 6V |

Top Zumo Speed @ 6V and 500g |

|

|---|---|---|---|---|---|

| 50:1 HP | 625 RPM | 15 oz·in | 1600 mA | 40 in/s | (100 cm/s) |

| 75:1 HP | 400 RPM | 22 oz·in | 1600 mA | 25 in/s | (65 cm/s) |

| 100:1 HP | 320 RPM | 30 oz·in | 1600 mA | 20 in/s | (50 cm/s) |

These three gearmotors are the ones we consider best suited for typical Zumo 32U4 applications (and many of our example programs are tuned to work with 75:1 HP motors), but we have many other gear ratios available that you can use when assembling the kit version of the Zumo 32U4 robot.

At this point, you might be wondering why it took so long for us to make an assembled Zumo 32U4 robot. Well, we have been working on several improvements to the Zumo 32U4 ever since releasing the kit, and we wanted to have them all in place before coming out with these more finished assembled products. The first improvement was to the sprockets, which changed from white with solid hubs to black with spokes. These new sprockets fit better on the motor shafts and make assembly and disassembly easier, and we think they just look cooler! They might also help you hide from your opponent’s IR sensors, but the color is of course no use against other sensing technologies like sonar.

|

|

The second improvement was to make a new component to hold and shield the IR LEDs used by the proximity sensor system. Without this, the LEDs are just supported by their leads and shielded by a piece of heat shrink (see the pictures above), and we wanted something better. Now the kit and assembled versions include a plastic LED holder that mounts directly to the front blade:

|

|

Finally, we have improved the blade. They are now stamped rather than laser-cut, and we have added cutouts around the general-purpose mounting holes so that they can be hand-bent to new angles as desired, independent of the blade angle. This new blade also has the chassis mounting tabs pre-bent to the appropriate angle, so that’s one less step required during assembly of the kit.

|

|

And speaking of the kit, we still strongly encourage people to get the Zumo 32U4 kit and build it themselves. We designed the Zumo 32U4 to be a starting point, and building it yourself will make you more comfortable with customizing and enhancing it. Making it yourself will also make it a little more meaningful when your robot triumphs over the competition!

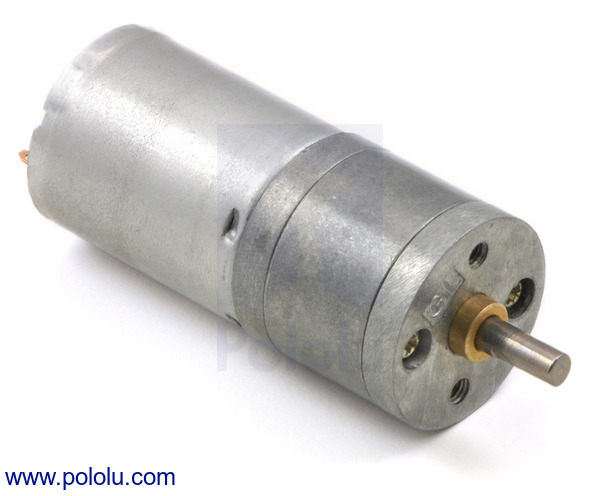

New products: 12V versions of the 25D mm metal gearmotors

|

Our 25D mm metal gearmotors are now available with 12 V motors in three power levels: High-Power (HP 12V) (5.5 A stall), Medium-Power (MP 12V) (2.1 A stall), and Low-Power (LP 12V) (1.1 A stall). The new 12 V LP motor can deliver approximately the same power as its 6 V counterpart, but since the voltage is doubled, it only requires half the current to do so, which means you can control it with lower-current, higher-voltage motor drivers like the DRV8801 or MAX14870 motor driver carriers. At their respective nominal voltages, the 12V HP motor has nearly the same free-run speed as the 6V HP motor, but it produces approximately twice the torque, which in turn means approximately double the output power. The 12V MP motors fall nicely between the 12V LP and HP options, offering a significantly more power than the LPs without the large current draw of the HPs. All five motor variants are the same size, which makes it easy to swap one for another if your design requirements change.

As with our original 6 V options, we have paired these new motors with a variety of gearboxes spanning gear ratios from 4.4:1 through 378:1. The result is 26 new versions, bringing our total selection of 25D mm metal gearmotors to more than 50 options. Unfortunately, we do not have encoder options for the 12 V motors yet, but we should have those later this year.

| Rated Voltage |

Motor Type | Stall Current @ Rated Voltage |

No-Load Speed @ Rated Voltage |

Approximate Stall Torque @ Rated Voltage |

With Encoder |

Without Encoder |

|---|---|---|---|---|---|---|

| 6 V | high-power (HP) |

6.5 A | 9800 RPM | 2 oz-in | 1:1 HP 6V w/encoder | |

| 2200 RPM | 8 oz-in | 4.4:1 HP 6V w/encoder | 4.4:1 HP 6V | |||

| 1000 RPM | 17 oz-in | 9.7:1 HP 6V w/encoder | 9.7:1 HP 6V | |||

| 480 RPM | 36 oz-in | 20.4:1 HP 6V | ||||

| 285 RPM | 60 oz-in | 34:1 HP 6V w/encoder | 34:1 HP 6V | |||

| 210 RPM | 80 oz-in | 47:1 HP 6V w/encoder | 47:1 HP 6V | |||

| 130 RPM | 130 oz-in | 75:1 HP 6V w/encoder | 75:1 HP 6V | |||

| 100 RPM | 160 oz-in | 99:1 HP 6V w/encoder | 99:1 HP 6V | |||

| 57 RPM | 260 oz-in | 172:1 HP 6V | ||||

| 6 V | low-power (LP) |

2.4 A | 6100 RPM | 1 oz-in | 1:1 LP 6V w/encoder | |

| 1400 RPM | 5 oz-in | 4.4:1 LP 6V | ||||

| 630 RPM | 11 oz-in | 9.7:1 LP 6V w/encoder | 9.7:1 LP 6V | |||

| 300 RPM | 24 oz-in | 20.4:1 LP 6V | ||||

| 180 RPM | 40 oz-in | 34:1 LP 6V w/encoder | 34:1 LP 6V | |||

| 130 RPM | 50 oz-in | 47:1 LP 6V w/encoder | 47:1 LP 6V | |||

| 82 RPM | 85 oz-in | 75:1 LP 6V w/encoder | 75:1 LP 6V | |||

| 62 RPM | 110 oz-in | 99:1 LP 6V | ||||

| 36 RPM | 170 oz-in | 172:1 LP 6V w/encoder | 172:1 LP 6V | |||

| 27 RPM | 220 oz-in | 227:1 LP 6V | ||||

| 16 RPM | 250 oz-in | 378:1 LP 6V | ||||

| 12 RPM | 300 oz-in | 499:1 LP 6V | ||||

| 12 V | high-power (HP) |

5.5 A | 2200 RPM | 23 oz-in | 4.4:1 HP 12V | |

| 1000 RPM | 44 oz-in | 9.7:1 HP 12V | ||||

| 480 RPM | 85 oz-in | 20.4:1 HP 12V | ||||

| 285 RPM | 120 oz-in | 34:1 HP 12V | ||||

| 210 RPM | 165 oz-in | 47:1 HP 12V | ||||

| 130 RPM | 240 oz-in | 75:1 HP 12V | ||||

| 100 RPM | 300 oz-in | 99:1 HP 12V | ||||

| 12 V | medium-power (MP) |

2.1 A | 1750 RPM | 11 oz-in | 4.4:1 MP 12V | |

| 800 RPM | 22 oz-in | 9.7:1 MP 12V | ||||

| 375 RPM | 42 oz-in | 20.4:1 MP 12V | ||||

| 225 RPM | 63 oz-in | 34:1 MP 12V | ||||

| 165 RPM | 85 oz-in | 47:1 MP 12V | ||||

| 100 RPM | 125 oz-in | 75:1 MP 12V | ||||

| 77 RPM | 165 oz-in | 99:1 MP 12V | ||||

| 45 RPM | 250 oz-in | 172:1 MP 12V | ||||

| 34 RPM | 320 oz-in | 227:1 MP 12V | ||||

| 12 V | low-power (LP) |

1.1 A | 1250 RPM | 8 oz-in | 4.4:1 LP 12V | |

| 570 RPM | 15 oz-in | 9.7:1 LP 12V | ||||

| 270 RPM | 29 oz-in | 20.4:1 LP 12V | ||||

| 160 RPM | 43 oz-in | 34:1 LP 12V | ||||

| 115 RPM | 60 oz-in | 47:1 LP 12V | ||||

| 75 RPM | 85 oz-in | 75:1 LP 12V | ||||

| 55 RPM | 115 oz-in | 99:1 LP 12V | ||||

| 32 RPM | 180 oz-in | 172:1 LP 12V | ||||

| 24 RPM | 240 oz-in | 227:1 LP 12V | ||||

| 15 RPM | 320 oz-in | 378:1 LP 12V | ||||

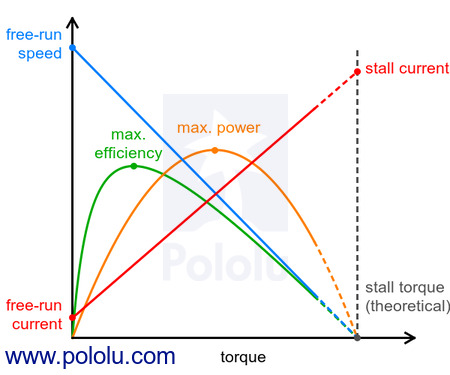

Keep in mind that stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. For these gearboxes, the recommended upper limit for instantaneous torque is 200 oz-in (15 kg-cm), and we strongly advise keeping applied loads well under this limit. Stalls can also result in rapid (potentially on the order of seconds) thermal damage to the motor windings and brushes, especially for the versions that use high-power (HP) motors; a general recommendation for brushed DC motor operation is 25% or less of the stall current.

|

Brushed DC motor performance curves. |

|---|

We list stall torques and currents for our gearmotors because these are end points of approximately linear DC motor performance curves shown above, and with them you can determine how the motor will behave as the voltage or load changes. For more information about how to generate specific performance curves for our gearmotors from the specifications we provide, see the first frequently asked question on any of the motor product pages.

Single-color packs of 3″ jumper wires

|

|

||

|

|

||

|

|

We have had a lot of requests for single-color packs of our 3″ Premium Jumper Wires and Wires with Pre-crimped Terminals, which until now have only been available in 50-piece rainbow packs like this. I am happy to announce that we have now added monochromatic 3″ packs in six colors: black, red, yellow, green, blue, and white. Multiply that by three different gender combinations (i.e. female-female, male-female, and male-male) and two styles (i.e. with or without housings), and that’s 36 new products in all!

New 1000:1 Micro Metal Gearmotors

|

We have two new versions of our Micro Metal Gearmotors with 1000:1 gearboxes: low-power with an extended motor shaft, which is useful if you want a very slow gearmotor with an option for encoder feedback, and medium power (MP). The main applications in which these motors shine are ones where slow, smooth motion is required. The high gear ratio also allows these gearmotors to generate high torque without drawing as much current or stressing the motor as much as if you tried to get comparable torque from versions with lower gear ratios, but at typical voltages you might not actually achieve a higher torque before the gears fail. (The stall torques we list are theoretical because these 1000:1 gearboxes can generate enough torque to destroy themselves before they get close to stalling!)

These new additions bring our Micro Metal Gearmotor selection to 57 (I have an idea for a Heinz joke to put here, but it’s not coming out very well), all of which can be found in our Micro Metal Gearmotor category.