Pololu Blog » User Profile: Arthur »

Posts by Arthur

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

Pololu laser-cut parts used by middle school team at the FIRST LEGO League championships

Last week, 7th-grade robotics team ‘Lightning Strikes Twice!’ (LS2!) from Aspen Middle School in Colorado joined 160 teams from 66 countries to compete in the FIRST LEGO League Challenge World Festival held in Houston, Texas. It was their first time qualifying after winning multiple first-place awards at an event in Fort Collins, Colorado last November, and second place at the Colorado State Championship in December.

LS2! designed an autonomous turtle robot to conduct coral reef research, which uses LEGO electronics and pieces to control the flipper mechanism. Pololu supported the team with laser-cut plywood pieces for mounting the paddles and acrylic pieces for the tail and watertight body with gasketed openings.

|

Turtle robot SHELTN2 submerged in a swimming pool. |

|---|

Working with Pololu was great. The parts arrived quickly and were very well packed. I suggested the students leave 3 mm of clearance around the LEGO structure to account for tolerance in the laser cutting and assembly but the parts were very accurate so we could have made it tighter. We used a combination of Weld-On 4 and 16 to glue the acrylic. The most challenging part was designing for the rubber shift boots we used to seal the joints while allowing movement. SHELTN’s total weight was approximately 7 kg plus 6 kg of ballast to achieve neutral buoyancy.

- William Gilmore, Mentor, Lightning Strikes Twice!

You can read more about the FIRST Championship in Houston in this FIRST press release, and visit the FIRST LEGO League blog for a full list of challenge and division award recipients.

We’re proud that parts from our Custom Laser Cutting Service helped LS2! bring their design to life and excel through their competition. Congrats to Lightning Strikes Twice! on all of their achievements!

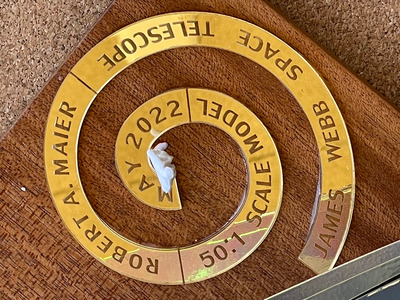

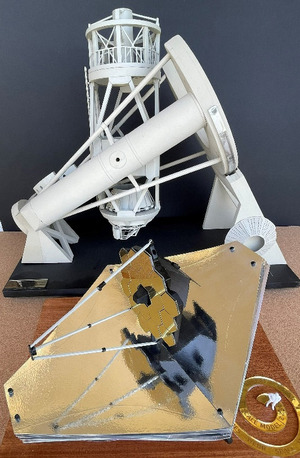

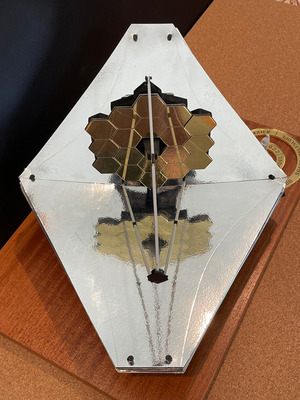

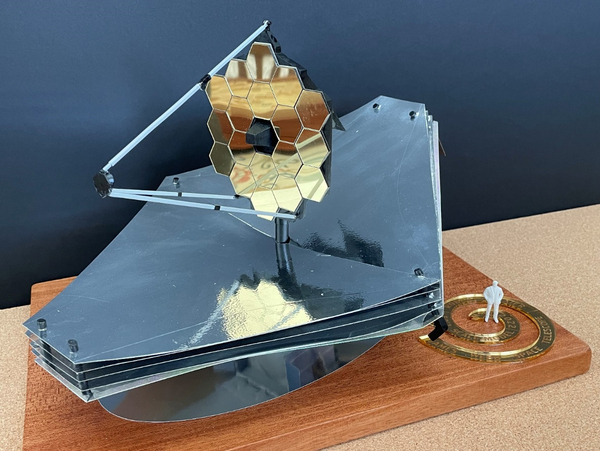

Laser cutting part of a 50:1 model of the James Webb Space Telescope

|

50:1 scale model of the James Web Space Telescope model with laser-cut and etched gold-mirror acrylic and gold-mirror styrene parts. |

|---|

Retired aerospace engineer Robert Maier shared with us this awesome 50:1 scale model of the James Webb Space Telescope (JWST) he made with his brother Mark and a little help from our custom laser cutting service. We cut the JWST’s main mirrors for him out of 1.5 mm gold mirrored styrene sheets from Midwest Products, and the hexagon patterns were laser etched onto the surface. He also had us laser cut various silicone bands to hold the moving pieces of the structure as the model folds/unfolds.

|

|

We more commonly work with 3 mm mirrored acrylic, but the model’s mirror required something thinner, and the more expensive styrene was perfect for the job. For comparison, the spiral label sitting beneath the figurine’s feet was cut from gold mirror acrylic.

|

|

Mark uses the model in the Astronomy 101 classes he teaches at San Jacinto College in Southern California. He recently wrote an article about the model, which is published in the April 2023 issue of Sky and Telescope magazine (it’s on page six). Additional photos of the model are included below, and even if you’re not a subscriber to the magazine, you can preview the article online.

Do you have a fun idea in mind that can benefit from laser-cut parts? Submit a quote request or contact us to discuss how we can help.

Starlite by Grant Grummer

Grant Grummer used our laser cutting service to create 6- and 8-point acrylic stars for his project, Starlite: A programmable star-shaped canvas for displaying light patterns.

Starlite uses a 3mm thick laser-cut piece of translucent white acrylic (#7328 white, also called “sign white”) for the front face. The LEDs mount onto a thinner (1.5mm thick) piece that has rectangular cutouts that allow the LEDs to connect to the controls, the main control board, and an UPduino daughter board.

You can read more about Starlite on Grant’s Make: Projects and GitHub pages.

If you are interested in making a similar light display, be sure to check out our selection of LED strips!

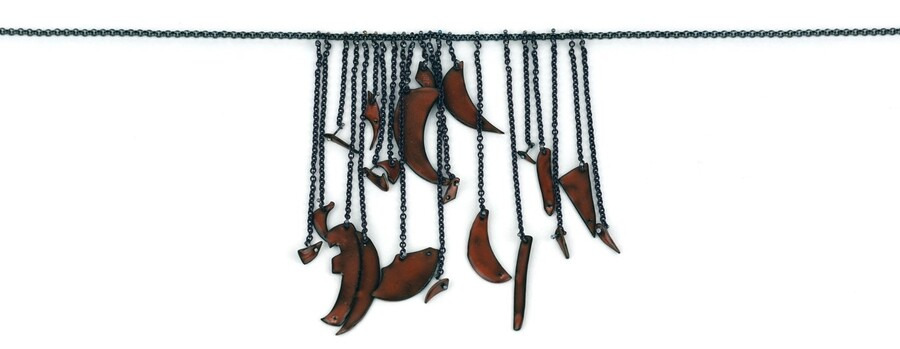

Laser-cut jewelry by Melissa Cameron

Laser cutting is an excellent way to make intricate parts for jewelry or decorations. These fantastic jewelry art pieces were designed by Melissa Cameron, an Australian-born artist based in Seattle, WA, who has work displayed in the collections of multiple art galleries, including the National Gallery of Australia. These pieces were cut from birch plywood and stainless steel using our laser cutting service. To get started on your own laser cutting project, submit a quote request here!

|

|

||

|

|||

|

|

|

|||

|

|

|

Steel custom laser cutting available

|

We’ve been offering quick-turn custom laser cutting service ever since “we” were just Candice and Jan operating a tabletop Epilog out of their home. Since then we’ve cut a wide assortment of customer designs including jewelry, engraved control panels, robot chassis, Christmas ornaments, and wedding invitations.

We started out mostly cutting acrylic, gradually moving into cutting a wider variety of plastics and wood. All along we’ve been improving our processes and increasing our capabilities by buying machines with bigger beds, better control systems, and more power. Without announcing it officially, we’ve been cutting metal for customers and ourselves over the past few years. For example, we cut our Basic Sumo Blade for the Zumo Chassis and the SMT stencils for our in-house electronics assembly. We’ve been refining our metal cutting processes and finding the best cut settings to minimize the chance of burring and dross, so most parts come out relatively clean and smooth to the touch.

The process quality has gotten to the level where we are comfortable announcing that metal laser cutting is generally available to customers!

|

|

|

||||||

|

|

|

||||||

|

|

|

You can see in the pictures above that laser-cut steel parts have a slight discoloration along the laser-cut edges caused by the chemical reaction that takes place when cutting. Depending on the steel type and whether the cuts are through the material, vector-etched line art, or raster-engraved filled-in areas, the discoloration is different (some tend to be brownish while others are a dark gray). We do not guarantee that parts will be free of blemishes; we ship the parts without any post processing, and we currently do not offer additional services such as deburring, tumbling, or bending.

As stocked materials (shown on our quote request page), we carry #304-2B stainless steel in 0.024″, 0.030″, 0.036″, 0.048″, 0.060", and mild steel in 0.030″ and 0.060″. We can arrange to use material you ship to us, but keep in mind that steel is the only metal we can cut. We cannot cut copper, brass, titanium, aluminum, or precious metals.

To get started on having your laser-cut steel parts cut, submit a quote request here.

Laser cut 6-string banjo frame

Here is a brief video a customer just sent us showing how he used our custom laser cutting service to create the frame on his custom 6-string banjo.

Odin sculpture and laser-cut model

DeWitt Godfrey, a sculptor and professor at Colgate University, used our custom laser cutting service to create a 15% scale polystyrene prototype model before moving on to the final full-sized sculpture. The final installation, located on the Colgate campus, measures approximately 40′ × 20′ and weighs 13 tons. In the video above, the styrene model appears at 2:10, and again at 2:40. You can also see a time-lapse video of the sculpture’s installation here.

|

15% scale model of Odin, a sculpture by DeWitt Godfrey. |

|---|

|

Interior photo of a 15% scale model of Odin, a sculpture by DeWitt Godfrey. |

|---|

ORBIS - Wooden Kinetic and Lighting Sculpture

Guido Bonelli Jr. of Innovative Electronic Solutions LLC created the ORBIS Wooden Kinetic and Lighting Sculpture for a client’s home using our custom laser cutting services. ORBIS hangs at 24″ in diameter and is 3/4″ thick. We laser-cut the parts from 1/8″ and 1/4″ baltic birch plywood, which were stained before assembly.

The separate control box and the wall unit each contain an Arduino Mega 2560 and an XBee module for wireless communication. The control box allows users to pick between two modes to control different features of the sculpture: kinetic mode allows users to adjust the rotating speed and direction of the two rings of the sculpture, and the color changing mode allows users to select various automated color patterns or control the red, green, and blue values individually to pick from 16 million colors.

|

|

For more information about ORBIS, check out the project’s web page.

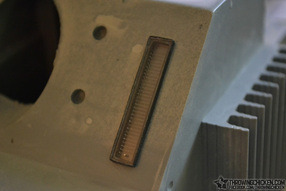

Power Level Indicator for Ghostbusters Proton Gun

Justin Chase Black (Throwing Chicken) is an artist and long-time laser cutting client who uses laser-cut parts in his prop and replica builds. Every time we ship a laser order to him, I eagerly await a new Facebook post showing off his latest project.

His work is extremely meticulous, skipping no detail in even the tiniest components. One of his more recent projects involves a tiny power level indicator on a “Proton Gun” replica from the movie Ghostbusters. Buying a power level indicator wasn’t an option; the ones he could find were made for aviation and cost over $1,000!

With a little trial and error, he was able to make them himself for a fraction of the cost by casting them out of resin, using our laser-cut parts to create the cast. A few of the design attempts did not come out well when cut from 1/8" acrylic since some of the features in the designs were much smaller than the thickness of the material (the design is only around 1/4" wide!). We cut various materials and thicknesses from 0.004" Mylar to 1/8" acrylic and a combination of thinner parts did the trick.

I’ll be sharing more awesome projects from Throwing Chicken in the future, but you can also check out his Artist page on Facebook for more updates. If you’d like to purchase a Ghostbusters Proton Gun Replica Kit, they’re sold on the Throwing Chicken Etsy shop.

If you have a cool project you’re working on and need some laser-cut parts: “Who ya gonna call?” (PO-LOLU!)

|

Power level indicator replica for Ghostbusters Proton Gun. |

|---|

|

|

||||

|

|

||||

|

|

||||

|

|

Personalize your own Christmas ornaments

|

Using our Custom Laser Cutting Service, you can design and cut your own Christmas ornaments. Whether this is to decorate your own tree (and show off to family and friends visiting), or to give away as gifts — personalized decorations are always a big hit for the holidays! We cut the following Pololu Christmas ornaments out of 1/8″ sapphire blue mirrored acrylic with a raster-engraved image, creating a reflective scene on a translucent background.

|

|

Let’s face it, we’re all a bit too familiar with last-minute Christmas shopping, and it’s not too late to order and have these in-hand by the holiday (though we’re getting close, so expedited service or shipping might be required)! The set of seven ornaments like the ones shown can be cut for our low minimum order charge of $25. Of course, since each person’s design will vary a bit, the exact price and quantity might vary. See our Custom Laser Cutting Guide for more information about how our laser cutting service works, or submit a quote request now to get started!