Support » Tic Stepper Motor Controller User’s Guide » 4. Setting up the controller »

4.8. Setting up RC speed control

This section explains how to set up the Tic to read a hobby RC servo signal and use that signal to control the speed of the stepper motor.

In this mode, the Tic will behave like an electronic speed controller (ESC), except with a stepper motor instead of a DC motor.

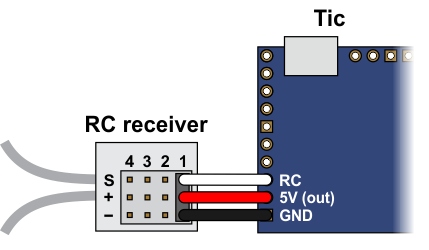

If you have not done so already, you should follow the instructions in Section 4.3 to configure and test your stepper motor. Next, with the system unpowered, connect your RC receiver to the Tic’s GND, 5V, and RC pins as shown in the diagram below.

|

In this configuration, the RC receiver will be powered by the Tic’s 5 V regulator via the 5V output pin. If you want to power the receiver from another power source instead, you should not connect the Tic’s 5V pin to it as doing so would short the two sources together and could damage the Tic or receiver.

If the Tic gets reset when you plug in your RC receiver, it might be because the in-rush current of the receiver is too much for the Tic’s 5V line and causes its voltage to drop temporarily. As general good engineering practice, we recommend making and breaking electrical connections only while your devices are powered off.

|

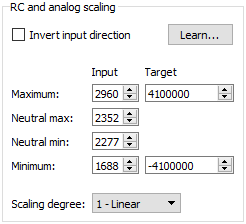

Example Tic scaling settings for RC speed control mode. |

|---|

Now connect the Tic to your computer via USB. In the Tic Control Center software, set the Tic’s control mode to “RC speed” and click “Apply settings”. In the “Scaling” box, click “Learn…” to start the Input Setup Wizard. The wizard will help you measure the neutral, maximum, and minimum positions of your RC signal. When the wizard is finished, it will set five of the input scaling parameters (input maximum, input neutral max, input neutral min, input minimum, and invert input direction) appropriately so that the neutral RC signal gets mapped to a velocity of 0, the maximum RC signal gets mapped to the target maximum, and the minimum RC signal gets mapped to the target minimum. You should change the target maximum to be equal to the maximum velocity that you want your motor to move in the forward/positive direction. Since you already set the “Max speed” parameter in the “Motor” box (see Section 4.3), you could just copy that value into the target maximum box. If you want your motor to go the same speed in both directions, you should set the target minimum to the negative of the target maximum. Otherwise, you should set the target minimum to be the lowest (most negative) velocity that you want your motor to have when moving in the other direction. Click “Apply settings” to save these settings to the Tic.

Now connect motor power and click “Resume” to start your system. If the Tic Control Center software says “Motor de-energized because of safe start violation.”, you should center your input. After doing that, you should be able to move your RC input to control the speed of the motor.

The safe-start feature helps prevent unexpected motion of the stepper motor by making sure that the stepper motor does not start moving until after your RC input goes to the neutral position. When you are starting up your system, you will always have to move your input to the neutral position if it was not there already. It is possible to disable this feature by checking the “Disable safe start” checkbox in the “Advanced settings” tab.

You should make sure that the motor is moving in the correct direction. If it is not, you can check the “Invert motor direction” checkbox to fix it. (You could also rewire the stepper motor to reverse the current in one coil, but be sure to turn off the stepper motor power before doing that.)

Finally, check the “Scaling degree” parameter. The default setting is “1 – Linear”. If you want finer control at low speeds and coarser control at high speeds, you can change it to one of the higher settings.

For details about what kind of RC signals the Tic can accept, and how the input scaling works, see Section 5.2.