Pololu Blog »

New 20D gearmotors available with 12 V windings and with long-life carbon brushes

|

We love motors here at Pololu, and we are committed to offering you the best selection so that you can find just the right drive solution for your project. Our latest efforts have gone into expanding our selection of 20D gearmotors to include 12 V versions, which have approximately the same performance at 12 V as our 6 V versions do at 6 V, just with half the current draw. This in turn enables the use of lower-current (and typically lower-cost) motor drivers in applications with access to higher voltages.

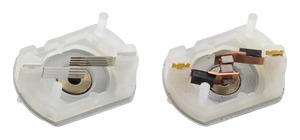

Additionally, we noticed that our original 6 V versions do not last as long as we would like in some applications, so we made these new 12 V versions with long-life carbon brushes instead of precious metal brushes, and we released new versions of our 6 V motors with long-life carbon brushes as well. These versions have “CB” in their names, and they can be differentiated from versions with precious metal brushes by their copper-colored terminals.

|

|

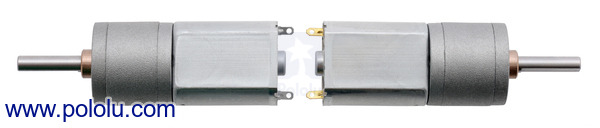

20D mm metal gearmotor precious metal brushes (left) next to 20D 6V CB and 12V CB long-life carbon brushes. |

|---|

Please note that making the brushes more robust can just move the failure point to the windings or gears if you try to push the motors too hard, but if you use them around their nominal voltages and keep the continuous load low (under around 20% of the stall torque or 1 kg-cm, whichever is lower), the carbon brushes allow the motors to last several times longer than versions with precious metal brushes.

Changing the brushes does affect the performance in ways beyond lifetime (e.g. the starting voltage is generally a little higher with the carbon brushes), so we are continuing to offer precious metal versions of our 6 V motors for now, but we might phase those out in the future. Please contact us or post a comment below if continued availability of the precious metal versions is important to you.

Currently, only the 6V versions with precious metal brushes are available with a rear motor shaft that can be used to add an encoder, like our magnetic encoder for 20D mm metal gearmotors, but the 6V CB and 12V CB motors should be available with this rear shaft option by the end of November.

With the addition of these new units, our selection of 20D gearmotors now spans nearly fifty options:

| Rated Voltage |

Brush Type | Stall Current @ Rated Voltage |

No-Load Speed @ Rated Voltage |

Approximate Stall Torque @ Rated Voltage |

Single-Shaft (Gearbox Only) |

Dual-Shaft (Gearbox & Motor) |

|---|---|---|---|---|---|---|

| 12 V | long-life carbon (CB) |

1.6 A | 570 RPM | 26 oz-in | 25:1 12V CB | |

| 450 RPM | 33 oz-in | 31:1 12V CB | ||||

| 225 RPM | 58 oz-in | 63:1 12V CB | ||||

| 180 RPM | 75 oz-in | 78:1 12V CB | ||||

| 140 RPM | 85 oz-in | 100:1 12V CB | ||||

| 110 RPM | 110 oz-in | 125:1 12V CB | ||||

| 90 RPM | 130 oz-in | 156:1 12V CB | ||||

| 72 RPM | 160 oz-in | 195:1 12V CB | ||||

| 57 RPM | 200 oz-in | 250:1 12V CB | ||||

| 45 RPM | 250 oz-in | 313:1 12V CB | ||||

| 36 RPM | 290 oz-in | 391:1 12V CB | ||||

| 29 RPM | 350 oz-in | 488:1 12V CB | ||||

| 6 V | long-life carbon (CB) |

2.9 A | 590 RPM | 22 oz-in | 25:1 6V CB | |

| 470 RPM | 28 oz-in | 31:1 6V CB | ||||

| 230 RPM | 54 oz-in | 63:1 6V CB | ||||

| 190 RPM | 62 oz-in | 78:1 6V CB | ||||

| 150 RPM | 72 oz-in | 100:1 6V CB | ||||

| 120 RPM | 87 oz-in | 125:1 6V CB | ||||

| 93 RPM | 110 oz-in | 156:1 6V CB | ||||

| 75 RPM | 130 oz-in | 195:1 6V CB | ||||

| 60 RPM | 170 oz-in | 250:1 6V CB | ||||

| 46 RPM | 220 oz-in | 313:1 6V CB | ||||

| 37 RPM | 260 oz-in | 391:1 6V CB | ||||

| 30 RPM | 310 oz-in | 488:1 6V CB | ||||

| 6 V | precious metal |

2.9 A | 590 RPM | 22 oz-in | 25:1 6V | 25:1 6V dual-shaft |

| 470 RPM | 28 oz-in | 31:1 6V | 31:1 6V dual-shaft | |||

| 230 RPM | 54 oz-in | 63:1 6V | 63:1 6V dual-shaft | |||

| 190 RPM | 62 oz-in | 78:1 6V | 78:1 6V dual-shaft | |||

| 150 RPM | 72 oz-in | 100:1 6V | 100:1 6V dual-shaft | |||

| 120 RPM | 87 oz-in | 125:1 6V | 125:1 6V dual-shaft | |||

| 93 RPM | 110 oz-in | 156:1 6V | 156:1 6V dual-shaft | |||

| 75 RPM | 130 oz-in | 195:1 6V | 195:1 6V dual-shaft | |||

| 60 RPM | 170 oz-in | 250:1 6V | 250:1 6V dual-shaft | |||

| 46 RPM | 220 oz-in | 313:1 6V | 313:1 6V dual-shaft | |||

| 37 RPM | 260 oz-in | 391:1 6V | 391:1 6V dual-shaft | |||

| 30 RPM | 310 oz-in | 488:1 6V | 488:1 6V dual-shaft | |||

Note: Stalling or overloading gearmotors can greatly decrease their lifetimes and even result in immediate damage. In order to avoid damaging the gearbox, we recommend keeping continuously applied loads under 50 oz-in (3.5 kg*cm) for the versions with precious metal brushes and under 70 oz-in (5 kg-cm) for the versions with carbon brushes (the ones with “CB” in the name). Stalls can also result in rapid (potentially on the order of a second) thermal damage to the motor windings and brushes, especially for motors like this that can deliver a lot of power for their size; a general recommendation for brushed DC motors is to limit continuous current to approximately 25% of the stall current.