Pololu Blog » Engage Your Brain »

February 2018 new equipment wrap-up: 3D AOI

My posts last month (here, here, and especially here) about the new electronics manufacturing equipment we installed focused on our new pick and place machine and stencil printer. This post is about the other major new machine we got at the same time, an automated optical inspection (AOI) machine from Mirtec.

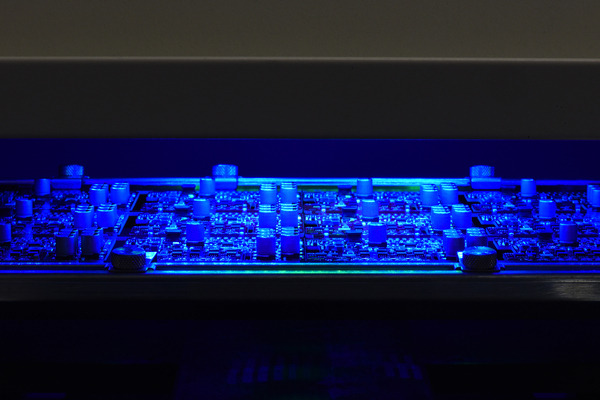

AOI machines have cameras that move around over an assembled board to take a bunch of pictures that then get processed to determine whether or not the board is assembled correctly. The machines often have several cameras that enable taking pictures from various angles, along with fancy lighting to variously illuminate the boards and components being inspected. Our AOI machines have rings of LEDs of different colors at different angles, so that, for example, red light highlights a different portion of a solder fillet than blue light. This picture shows a panel of our Dual G2 High-Power Motor Drivers in one of our older AOI machines:

|

A panel of Dual G2 High-Power Motor Drivers illuminated by blue LEDs during automated optical inspection (AOI). |

|---|

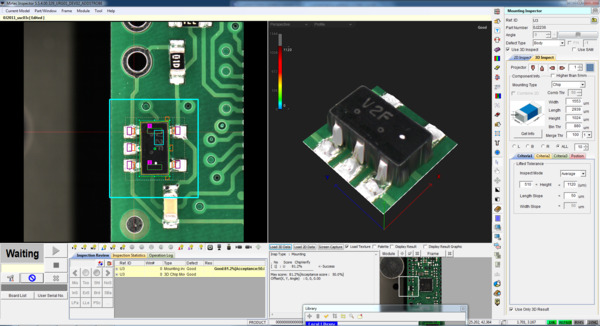

The tricks with lighting are basically attempts to generate more three-dimensional information than you can get with just 2D pictures out of a camera. What is exciting about our new machine is that in addition to the traditional lighting and cameras, it also has a sophisticated sensor for doing precise height measurements everywhere along a component. Machines with this kind of sensor are called 3D AOI machines.

|

5-pin SOT-23 component getting set up for 3D automated optical inspection (AOI). |

|---|

The machine we got is Mirtec’s latest AOI machine, the MV-3 OMNI, which is a desktop or batch version of their inline inspection machine that has the same technology. I ordered the machine with the optional stand, which turned out to be a good thing because for a desktop machine, this thing is huge. The crate was much larger than I expected, and while not requiring a 10,000 pound forklift rental like the pick and place machine, we did have to use our fork extensions.

|

|

Out of the crate, the machine and stand are quite a bit smaller. Something to keep in mind for anyone considering such a machine is that this one is too big to fit through a single three-foot door.

|

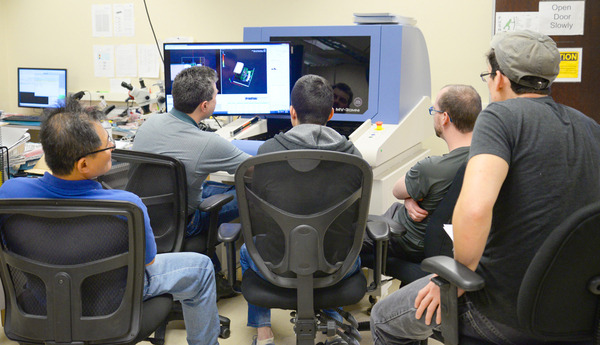

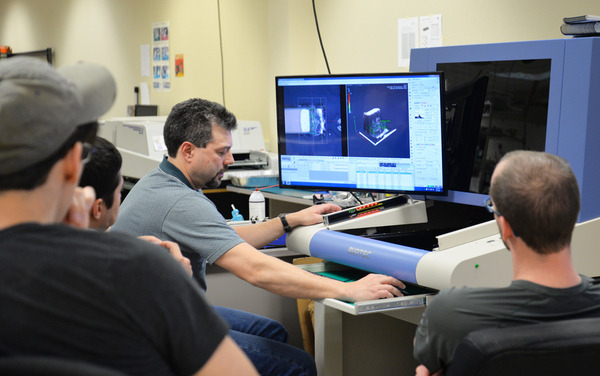

We had an especially busy week, with the installation and training for the AOI machine happening at the same time we were doing the Europlacer pick and place machine and stencil printer installation that I wrote about earlier.

|

|

Mirtec MV-3 OMNI 3D AOI machine training. |

|---|

|

Our Yestech AOI machines are visible in the background of that last training photo. (They are also featured in our The Manufacturing of A-Star 32U4 Micro video.) We already performed 100% AOI on every board we made before we got this latest machine. We are happy with those machines, and since we had two, capacity and redundancy were not primary motivations for getting this new one. With any piece of equipment like this, the challenge is to find every possible defect without generating a lot of false positives. If the settings are too lax, or the machine is not capable enough, defects will make it through, but it’s not enough to just flag every mismatched pixel since the ultimate authority is still the human operator that inspects every spot the machine identifies as suspect. If the machine inundates the operator with a thousand possible defects for every actual defect, the operator is likely to miss the one actual problem. It’s difficult to characterize this since there are many different components and every design is different, plus how we set up or train the machines also matters a lot.

|

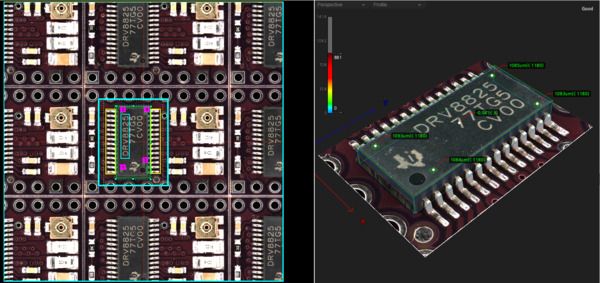

3D automated optical inspection (AOI) setup for Pololu DRV8825 stepper motor driver carrier. |

|---|

So, the main motivation for getting this new machine was the hope that it will give us more capabilities going forward to have the highest possible confidence in the quality of our products. The new machine is almost twice the cost of the older ones, and especially with the 3D capability, it should be able to deliver that. Our first impressions have been very positive, but to really know, it will take some time to get familiar with the machine’s strengths and weaknesses and to integrate it well into our manufacturing processes.

|

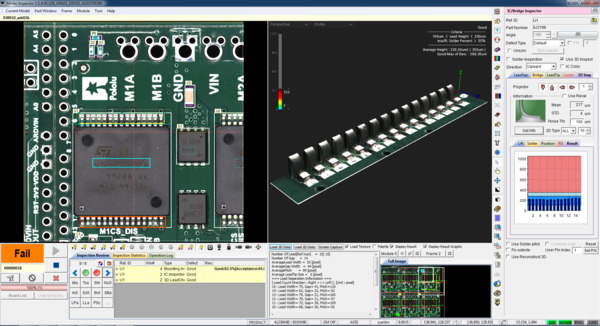

3D automated optical inspection (AOI) setup for Pololu Dual VNH5019 Motor Driver Shield for Arduino. |

|---|