Pololu Blog » Engage Your Brain »

How I picked our new machines (and what they mean for you!)

|

The new equipment I have been sharing for the past two weeks (here and here) represents our biggest manufacturing capacity increase in five years. Today I will go into more detail about the pick and place machine and stencil printer we got, along with what it means for our customers.

Assembling a circuit board with surface-mounted components involves three main steps: printing solder paste on a bare circuit board, placing the components on the board, and then sending the board through an oven, which melts the solder paste, soldering the components to the board. You can see the steps in this video we made a while ago about how the A-Star 32U4 Micro gets made:

Pick and place machine

At the end of 2012, we got two very different pick and place machines, an SM421F from Samsung (which has since sold their electronics assembly equipment business to Hanwha) and an iineo from Europlacer. Both machines are very versatile, designed to place everything from the smallest components to large and tall parts, and we have run all of our products on both machines. I got both machines back then because each manufacturer made a compelling case, and I wanted to try both. The new machine we installed this month is another Europlacer machine. So… does that mean it’s better?

First off, the Europlacer machine is much bigger and more expensive than the Samsung/Hanwha machines, so the real comparison for this round of new equipment was two Hanwha machines vs. one from Europlacer. Each SM482 Plus has 120 feeder slots, so two of those machines have very similar feeder capacity to the 264 slots of the iineo+. The pair of Hanwha machines is also similar to the Europlacer option in terms of combined size and price. I should also say that we have had a great experience with both machines and vendors, and I do not regret having bought either of those machines in 2012. The Hanwha machine route had one major advantage: the machines, even individually, are faster than the Europlacer in the straight parts per hour component placement rate; with two of them, it should be no contest, with a combined advertised placement rate of around 60,000 components per hour vs. around 15,000 for the Europlacer machine. Having two smaller machines would also give us some more flexibility (we could operate them as two separate machines, running different products, as opposed to one big machine) and redundancy, so that we could keep at least some production running if one machine went down. The redundancy argument probably would have pushed me in the direction of the Hanwha, two-machine route, if we didn’t already have any other machines.

|

But we did already have a Europlacer machine, so getting a second one would give us that redundancy. And despite the sustained placement rate being four times lower, we expect the Europlacer to actually be the faster option for our purposes. That’s because our products tend to be relatively small and simple, but we have hundreds of different products (and I want it to be thousands soon), so we need to be able to run many different products a day efficiently. We might get some of that efficiency from the Europlacer software, though it’s not that clear to me that there really is that much difference between the machines (as opposed to operator familiarity). The interchangeable carts should also help eventually, though I do not expect that to make much of an impact until we have more of them, and so far we just have enough to basically fill each machine. What I think matters the most is the huge feeder count on a single machine, minimizing the amount of component changes that have to be made from one product to the next. It’s inevitable that the raw throughput will be lower when the placement head has to on average travel farther from the board being assembled to the part in the machine, but for our mix of quantities, it’s worth it.

|

132 feeder locations across four carts on the back side of the Europlacer iineo+ machine. There are 132 more on the other side! |

|---|

Stencil printer

For solder paste printing, I thought some more about a jet printer. The general idea is that the printer has the solder paste in a cartridge that moves all over the bare circuit board and squirts some on every pad, as opposed to squeegeeing a bead of solder paste through a stencil the way solder paste is more typically applied. I have been looking at MyData’s jet printers since they came out probably over ten years ago now, and the prospect of not needing stencils and being able to vary deposit thicknesses keeps being attractive, especially for our scenario where I want to be able to do just a few panels each of many different designs every day. But, at more than double the cost of a traditional stencil printer, the cost seems difficult to justify, especially since we cut our own stencils in-house. So, I ended up ordering another stencil printer from Europlacer since we are happy with the one we already have. MyData is now Mycronic, and you can see more about their jet printer at the Mycronic Jet Printer page.

|

The technician from Europlacer performing the installations was disappointed that we were pairing the nice new color-coordinated stencil printer with our Samsung pick and place machine. |

|---|

Commitment to better manufacturing and lower prices

What does all this mean for our customers? (Other than a higher likelihood of getting to see an awesome machine running when you come visit us.) Partly I am sharing this because I expect most of you like making things, like to see how things get made, and would love to have machines like this of your own. More importantly, I want to remind you of the effort we are going through to bring you better products at lower prices. Having more of this extremely flexible manufacturing capacity means we can keep churning out new prototypes quickly and then be able to manufacture the products at a globally competitive price. Over the coming months, we will be assessing our manufacturing costs and lowering prices on many of our popular products, and new products will have lower prices as soon as we introduce them.

We are kicking that off with a substantial price cut on our popular time of flight distance sensors:

|

|

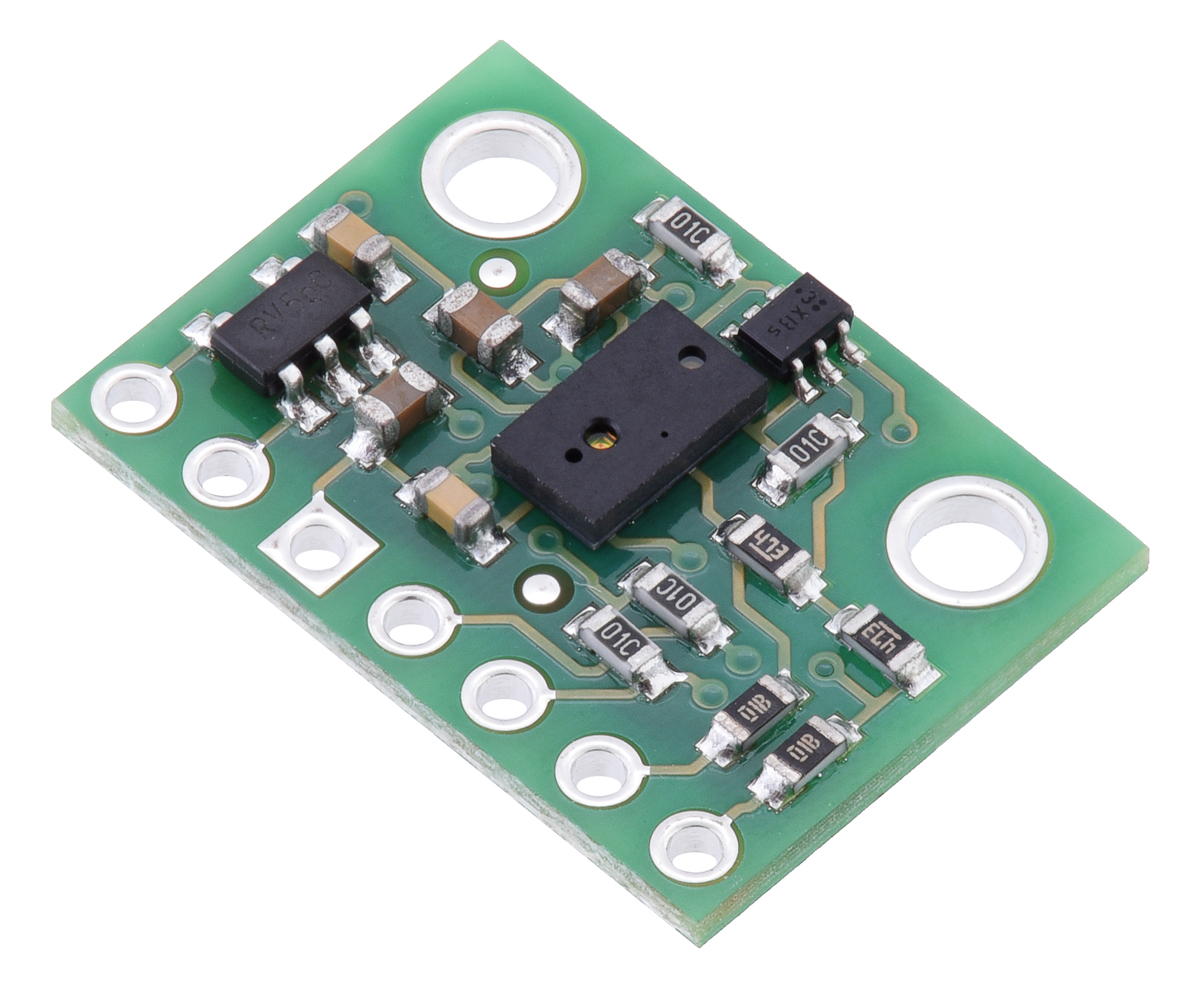

| VL6180X Time-of-Flight Distance Sensor Carrier with Voltage Regulator, 60cm max |

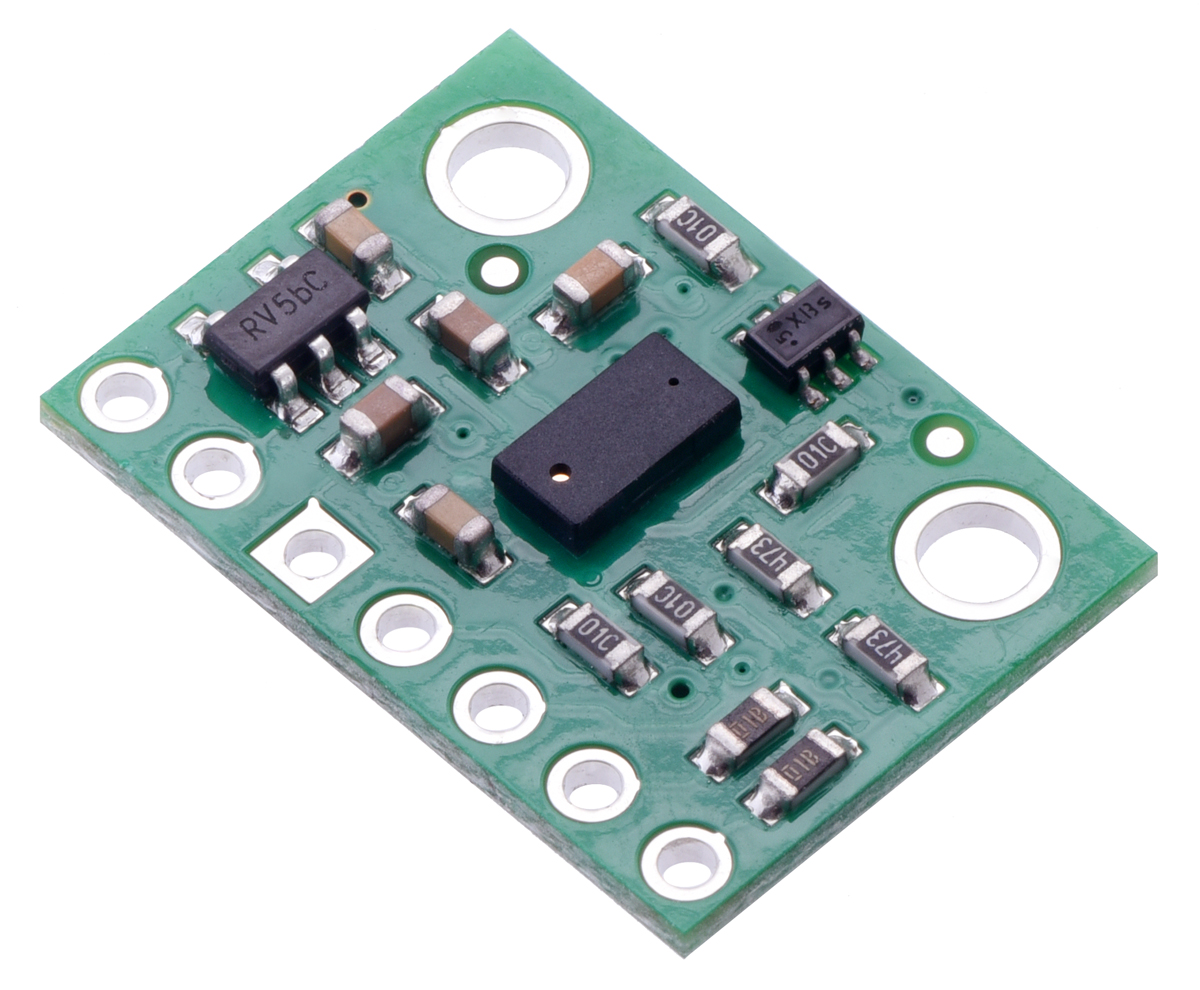

VL53L0X Time-of-Flight Distance Sensor Carrier with Voltage Regulator, 200cm Max |

And to help everyone share in our excitement, we’re offering the new, low, 100-piece pricing at single-unit quantities to the first 100 customers using coupon codes 2489PRICECUT and 2490PRICECUT (Click to add both coupon codes to your cart).

2 comments

- Jan