Support » Pololu Simple Motor Controller User’s Guide » 4. Connecting Your Motor Controller »

4.1. Connecting Power and a Motor

Warning: Take proper safety precautions when using high-power electronics. Make sure you know what you are doing when using high voltages or currents! During normal operation, this product can get hot enough to burn you. Take care when handling this product or other components connected to it.

The first step in using your Simple Motor Controller is connecting power and a motor. With those connections in place, you can immediately start testing with the Simple Motor Control Center. The following section explains the power system in detail.

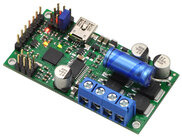

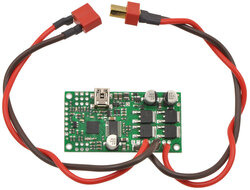

|

Simple Motor Controller 18v7 power and motor connections. |

|---|

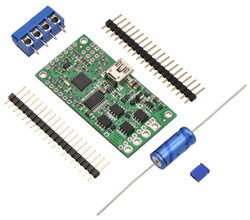

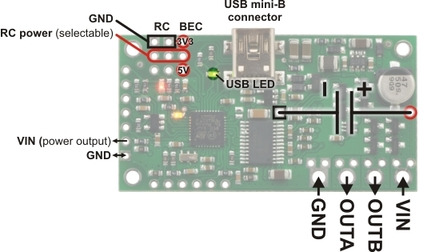

|

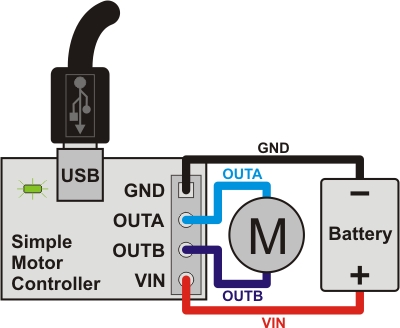

Simple High-Power Motor Controller 18v15 or 24v12 power and motor connections. |

|---|

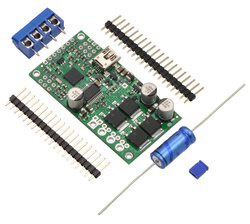

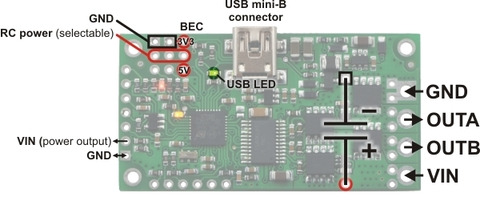

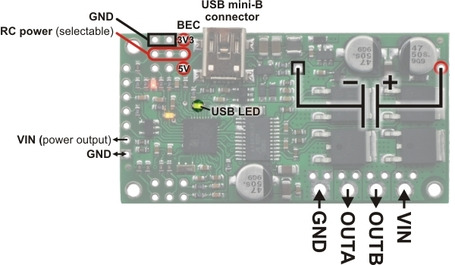

|

Simple High-Power Motor Controller 18v25 or 24v23 power and motor connections. |

|---|

Power Considerations

The Pololu Simple Motor Controllers can be powered either from USB using a USB A to mini-B cable or from a power supply, such as a battery pack, connected to the large VIN and GND pads. When the VIN supply is not present, the controller can use USB power to perform all of its functions except for driving the motor. The controller automatically selects VIN as the power source when it is present, even when USB is connected. It is OK to have both USB and VIN power simultaneously connected.

Power for the motor must be supplied to the controller through the large VIN and GND pads. The smaller VIN and GND pads on the left side of the board in the diagrams above are not suitable for high currents and should not be used to power the motor controller. These smaller power pins provide a convenient way to pass the input voltage on to other parts in your system, but they should not be used to power anything that will draw more than 500 mA.

All Simple Motor Controller versions can operate from VIN supplies as low as 5.5 V, but the maximum continuous output current will be lower for voltages under 7 V. The maximum power ratings for the Simple Motor Controllers are shown below:

| Simple Motor Controller | 18v7 | 18v15 | 24v12 | 18v25 | 24v23 |

|---|---|---|---|---|---|

| Absolute max voltage | 30 V | 30 V | 40 V | 30 V | 40 V |

| Recommended max voltage | 24 V | 24 V | 34 V | 24 V | 34 V |

| Max continuous current w/o heat sink | 7 A | 15 A | 12 A | 25 A | 23 A |

It is very important that you select a power source that does not exceed the absolute maximum voltage rating for your Simple Motor Controller. Ripple voltage on the supply line can raise the maximum voltage to more than the average or intended voltage, so we recommend you to select a voltage that leaves at least a 6 V margin for noise. It is also important to note that batteries can be much higher than their nominal voltage when fully charged, so we do not recommend using the 18v7, 18v15, or 18v25 versions with 24 V batteries unless appropriate measures are taken to limit the peak voltage.

For 24 V applications, we recommend the 24v12 or 24v23 versions. We strongly recommend against using the 18v7, 18v15, or 18v25 with 24 V batteries, which can significantly exceed 24 V when fully charged and are dangerously close to the maximum voltage limits of these lower-voltage controllers. Using a 24 V battery with an 18vX Simple Motor Controller makes the device much more susceptible to damage from power supply noise or LC voltage spikes.

Finally, make sure you select a power source that is capable of delivering the current your motor will require (e.g. alkaline cells are typically poor choices for high-current applications), and place a large capacitor across power and ground near the motor controller to limit electrical noise (such a capacitor is pre-installed on fully-assembled 18v7, 18v15, and 24v12 controller versions).

The Simple Motor Controllers feature a configurable low-voltage shutoff that can help you avoid damaging batteries that are sensitive to over-discharging, such as Li-Po packs. See Section 5 for more information.

Motor Considerations

|

The two terminals of your brushed, DC motor connect to the OUTA and OUTB pins. When selecting a motor for your controller (or a controller version for your motor), it is important to consider how the motor will be used in your system. If the motor is likely to be stalled for prolonged periods of time or under heavy load, or if the motor will be rapidly changing direction without acceleration limiting enabled, you should be taking into account the stall current of the motor at the voltage it will be running and selecting a controller that can deliver a continuous current that exceeds the stall current.

It is not unusual for the stall current of a motor to be an order of magnitude (10×) higher than its free-run current. When a motor is supplied with full power from rest, it briefly draws the full stall current, and it draws nearly twice the stall current if abruptly switched from full speed in one direction to full speed in the other direction.

Occasionally, electrical noise from a motor can interfere with the rest of the system. This can depend on a number of factors, including the power supply, system wiring, and the quality of the motor. If you notice parts of your system behaving strangely when the motor is active (e.g. corrupted serial data, bad RC pulses, noisy analog voltage readings, or the motor controller randomly resetting), consider taking the following steps to decrease the impact of motor-induced electrical noise on the rest of your system:

- Solder a 0.1 µF ceramic capacitor across the terminals of your motor, or solder one capacitor from each terminal to the motor case. For the greatest noise suppression, you can use three capacitors (one across the terminals and one from each terminal to the case).

- Make your motor leads as thick and as short as possible, and twist them around each other. It is also beneficial to do this with your power supply leads.

- Route your motor and power leads away from your logic connections if possible.

- Place decoupling capacitors (also known as “bypass capacitors”) across power and ground near any electronics you want to isolate from noise.

Power and Motor Connectors

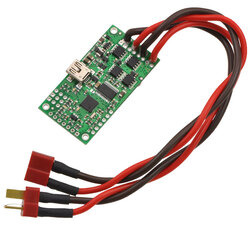

|

|

|

The fully-assembled 18v7, 18v15, and 24v12 Simple Motor Controller versions ship with terminal blocks soldered into the large VIN, OUTA, OUTB, and GND pads and a power capacitor pre-installed, as shown in the pictures above. These terminal blocks make it easy to connect and disconnect power supplies, but they are only rated for 15 A.

All other versions ship with terminal blocks and a power capacitor included but not installed, which provides flexibility in making connections. These versions offer two options for connecting to the high-power signals (VIN, OUTA, OUTB, GND): large holes on 0.2" centers, which are compatible with the included terminal blocks, and pairs of 0.1"-spaced holes, which are compatible with the included 0.1" male header strip and can be used with perfboards, breadboards, and 0.1" connectors. For high-power applications that exceed the 15 A rating of the terminal blocks, we recommend soldering thick wires directly to a connector-free version of the board and using higher-current connectors (see the custom-connector pictures above). Another benefit of the connector-free version is flexibility in placement of the power capacitor (e.g. on the other side of the board) to accommodate compact installations or to make room for a heat sink. The power capacitor has a significant effect on performance; the included capacitor is the minimum size recommended, and bigger ones can be added if there is space. A bigger capacitor might be required if the power supply is poor or far (more than about a foot) from the controller. The pin-out diagrams above show where you can connect the included (or your own larger) power capacitor.

Logic Power

The Simple Motor Controllers use 3.3 V logic, but all of the controllers’ digital inputs are 5V-tolerant, so it can interface directly with 5V systems. The only pins on the board that cannot tolerate 5V are the two analog input channels, A1 and A2. The simple motor controllers incorporate both a 5V regulator and a 3.3V regulator, but the 5V regulator is only used when power is supplied to VIN. Otherwise, the USB 5V bus voltage replaces the output of the 5V regulator. The 5V and 3.3V power buses are available via the RC BEC jumper pads (see the upper-right corners of the power connection diagrams above), and a shorting block can be used to connect the RC power row to the desired voltage rail, thereby powering a connected RC receiver with 3.3 or 5 V. These pins can also be used to supply approximately 150 mA to other components in your system.

Trying Out the Controller with USB

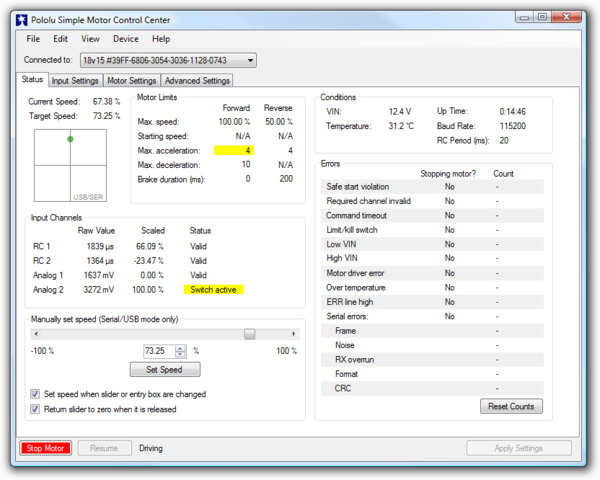

Once you have a connected a power supply and a motor, you can use the Simple Motor Control Center to make the motor move and test how various settings affect the behavior of the motor (see Section 5 for more information on configuring the Simple Motor Controller). The Simple Motor Controller defaults to “Serial/USB” input mode, which lets you control the motor speed with the slider bar under the status tab. If you have already changed the input mode of the device to something else, you can restore it by going to the Input Settings tab, selecting Serial/USB as the Input Mode, and clicking the Apply Settings button in the lower right corner.

|

Status tab in the Pololu Simple Motor Control Center. |

|---|

Before you can move the motor, you will probably need to click the green Resume button in the lower left corner to clear the safe-start violation. If the Resume button is grayed out, there are errors that are preventing the motor from moving. See Section 3.4 for information on how to identify and fix errors.

Safe Start is an optional feature, enabled by default, that makes it less likely that the motor will start moving unexpectedly.