Support » Custom Laser Cutting Guide »

3. Limitations and issues to consider

|

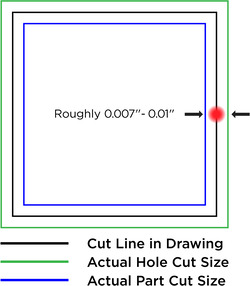

The kerf of our laser is roughly 0.007" – 0.01" which causes parts to be slightly smaller and have larger holes than how they are drawn. |

|---|

|

An example of melting along sharp angles for various thicknesses of acrylic (1.5 mm to 12 mm). |

|---|

There are some limitations to the laser-cutting and UV printing processes that are important to keep in mind:

Laser cutting geometry limitations

- We can only cut two-dimensionally – no 3D designs, or beveled edges.

- We can adjust machine settings to control the approximate engraving depths, but we cannot promise precise depths and advise against excessive engravings to avoid parts from warping.

- All laser-cut dimensions will vary slightly due to the laser’s kerf (beam width). While we typically expect a kerf width of ~0.007″ – 0.010″ (~0.18 mm – 0.25 mm), we do not guarantee any particular tolerance as there are many factors that affect the exact kerf size (material type, material thickness, material flatness, size and shape of your part and overall layout, and more).

- The laser’s beam is cone-shaped which causes the parts to have a slight (~1° – 2°) taper. The kerf width is smaller on the front than it is on the back of the material.

- The laser’s beam is not perfectly circular, which means squares will not be perfectly square, and circles are not perfectly circular (for parts that need to be perfectly circular, we suggest cutting smaller holes and cleaning them up with a drill).

- We highly recommend having no areas that are narrower than the thickness of the material you are using. Having cut lines too close together can sometimes cause the material between the cuts to break, melt, warp, or become brittle due to the heat from the laser. This includes parts with sharp angles that narrow into a sharp tip.

- Most sheet material thicknesses can vary slightly, and different materials have different thickness tolerances. We cannot promise anything beyond what the material manufacturers do, nor do we offer material pre-screening.

Material and handling limitations

- Laser cutting causes noticeable discoloration or charing along the edges of some materials such as wood, paper, rubbers, and fabrics.

- Some materials (e.g. acrylic) come with a protective film or paper masking layer applied to the surface while other materials do not (e.g., ABS, Delrin, styrene, MDF, plywood). We typically cut and ship the materials as they are when we receive them, but we can add masking upon request. (We charge more to mask materials.)

- Parts cut from materials with masking will ship with the masking still on. (We have a video that shows an easy way to unmask acrylic.)

- Parts cut from materials without masking may have burn markings from the cutting process.

- Other than UV printing, we do not offer any post-cutting services such as deburring, tumbling, polishing, bending, welding, anodizing, or coating. We ship parts as cut.

- Blemishes and light scratches may affect the surfaces of materials like metals and some plastics we receive unmasked.

- Laser cutting metals may cause slight discoloration, dross formation, and burring. Typically, burring is minimal for metals under 1/8″ thick, but is more severe for thicker materials.

- The material sits on a metal grid during cutting. When the laser cuts through the material, it hits the grid and bounces back and hits the bottom of the material, causing a small dent or mark. The backs of the parts will usually have small dents along the cut edges of the part wherever the laser, grid, and material meet.

- For more material-specific information, please see Section 5.

UV printing limitations

- While we can print onto many common laser cutting materials, we cannot print onto all of the materials we can laser cut.

- To check what materials we can and cannot print onto, please see Section 5.

- Our inks work best on rigid materials, and the prints do not hold up well to being bent or stretched.

- Ink adhesion strength depends on the material, whether primer is used, and the size/geometry of the artwork.

- We typically expect the alignment between printed artwork and laser cut geometry to be around 0.010″ (0.25 mm), but we do not guarantee any particular tolerance.

- For designs where it is important for artwork to go all the way to the part edge, we recommend including at least a 0.020″ (0.5 mm) bleed past the cut lines, but please note that this might result in some ink getting along the side edges of the part.

- We decide whether to print before or after laser cutting on a case-by-case basis. If you have specific needs or concerns, please mention them when you submit your quote request.