Pololu Blog » Engage Your Brain »

Three and a half months to plug in our machines legally

This post is an account of the difficulties I have had for the past four months in getting permits to run our equipment at our new location, which we moved to in December of 2011. I am writing this partly as notes for myself and others at Pololu, but the main point of sharing this is to warn and commiserate with other businesses having to deal with such problems and to give other readers some awareness of the real-world ramifications of the regulations much of the public seems all too eager to embrace. I still have a hard time believing we really had to go through all of the hassle and expense, so I am also hoping that some readers might point me to some resources so that I can avoid this in the future. I realize there is speculation and hearsay in my report, but I want to emphasize that my impressions are based on many vendors, contractors, public employees, and manufacturers: in all, I spoke to dozens of people about our experience. I will try to be as specific as practical without unnecessarily exposing individuals who were trying to be helpful to undue scrutiny.

Scope of the installation

Our manufacturing consists primarily of laser cutting and electronics assembly. Our assembly equipment is on the entry-level side as far as electronics manufacturing goes, so most of the machines run on 120V available from regular wall outlets; the main exceptions are the reflow ovens, which typically use 3-phase power and need some kind of exhaust to get rid of the flux fumes. At our previous location on 3095 E. Patrick Ln., we had a single roof-mounted exhaust blower for one oven and three laser cutters. The picture below shows the main exhaust duct going to the ceiling, a branch going to the left to the assembly room, and a pair of ducts going to our laser exhaust filter, which is the white box at the bottom:

|

Warehouse exhaust ducts at 3095 E. Patrick. |

|---|

On the other side of the wall on the left, the exhaust duct connected to the reflow oven:

|

Reflow oven exhaust duct at 3095 E. Patrick. |

|---|

That work was all permitted, as far as I knew (more on that later), when we moved into that location in late 2009. The non-electrical part, including getting the crane out there to hoist the exhaust blower on the roof, took about two days and cost $2,300. (The electrical portion cost almost $9k, but there was a lot of other work involved.)

As I mentioned in my previous post, one of the features of our new location is better power, and we took advantage of that right away by getting a higher-power laser cutter and a bigger oven. To accommodate the extra equipment and the larger space, my plan was to install three exhaust blowers: two in the warehouse, where we now have four laser cutters, and one in the electronics manufacturing room, where we can have up to three reflow ovens. The completed setup looks like this (the third oven, on the right, is not connected; the duct sticks out a few inches from the ceiling to the right of the door):

|

Reflow oven exhaust ducts at 920 Pilot. |

|---|

The complete warehouse exhaust ducts for the laser cutters look like this:

|

Warehouse exhaust ducts at 920 Pilot. |

|---|

Target schedule

Our building leases gave us these restrictions: we could access our new space in November to start setting it up, we could start operating out of it in December, and we had the old location through the end of the year. My initial plan was to have the electrical work and duct work completed by early December so that we could have some machines up and running in the new location before taking down any machines at the old location. The new machines started arriving in November, and before Thanksgiving, we had the details of the layout figured out, HVAC guys and electricians selected, and landlord approval for the work. I was getting a little concerned because of the holidays slowing things down, but based on earlier experience and the contractors’ estimates, it seemed like basic work could be completed in the first full week of December, with everything getting wrapped up the week after that, leaving us two weeks to get the machines moved from the old location.

The contractors I was getting quotes from had varying degrees of concern about permits taking a longer time lately, but they all indicated the schedule was doable and that they could work on it in parallel, taking care of the paperwork while getting materials to the site and doing things like the sheet metal work for the ducts.

Besides completing the work in time to move our equipment, the other major scheduling concern had to do with installations of the new machines, which for tax purposes had to get completed in 2011. This was less of an issue with machines we could get up and running ourselves, but the new reflow oven in particular was a concern. One of the reasons I went with Heller was their assurance that I could have a 480V version delivered in the time frame I needed, and they could do that because they already had a 208V unit that they could convert to 480V. That modification would get done by the technician that installed the machine, and he would require power to be available at the machine to do his job.

Permit denied

The first indication that obtaining a permit would not be as trivial as in the past was when the HVAC contractor started coming back with more questions about the details of the machines we were connecting. In the past, general descriptions had been enough, but now we were being asked for more specifics and manufacturers and model numbers. I mentioned we had not had to provide that before, but I figured that there was nothing to hide and that perhaps providing the extra info would move things along, so I did not really think too much of it.

The project took a sudden turn into uncharted territory for me when the main electrician called, saying the Building Department was not even accepting his application for a permit (as opposed to accepting the application and then denying a permit). I do not know the workings of the permit process—I do not even know if I should refer to an electrician as a contractor or what to call his company without sounding like I’m talking about the electrical utility company—so I probably have some of the details wrong here, but the gist of it was that the electricians had hit a dead end of a sort they had not encountered before. The main contact I was talking to was basically saying he was at his wits’ end and was asking me to call some manager at the Building Department. I explained that I had no idea how this permit stuff works and that I had little hope of instigating any progress if he did not know what to do.

But, with no other immediate option, I called, figuring I could at least find out if the county viewed my electrical contractor as particularly incompetent. Apparently, some combination of the mechanical and electrical permits being applied for separately, combined with the amount of power and volume of exhaust, had raised some flags. I vaguely remember the guy saying something about being concerned about unsafe wood or cabinetry shops. I assured him that there was no sawdust involved in our operation and tried to explain what we do. He asked me and my contractors to meet with him the next morning, when we could make sure any concerns the inspectors raised could get addressed at once to expedite the process.

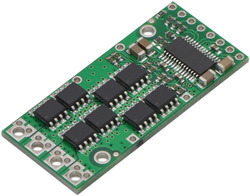

|

The next morning, I went to the Clark County Building Department main office as prepared as I could be: I had manuals for the machines, pictures of our old setup, including the pictures above, sample assembled boards to show the kinds of things we manufacture, and a plaque we received when we completed OSHA’s SHARP, a proactive safety consultation for small businesses. I was getting mixed advice from the contractors, but I was unsettled by the parts that sounded like other advice I generally hear about when dealing with the government: say as little as possible. My thought was that if I could establish that we weren’t doing anything shady and that we had been doing this kind of thing for years with the appropriate permits and government blessings, they might just need to double check some specifications about the machines, which would be covered by the manuals, and we’d be set. And, for the most part, that’s how it went. The manager seemed to agree that this was a small project that should be easy to get approved, and he understood that we had a tight schedule; he did not personally look over and approve permit applications, but he would make sure he was on top of the guys actually doing that.

One issue that the HVAC contractor was having even before the meeting had to do with UL labels on the machines. Apparently, the person reviewing the mechanical permit wanted confirmation that the machines had these labels, and the contractor made several trips to our facilities (old machines at old place, new machines at new place) to look for some kind of acceptable label. Unfortunately, none of the machines had UL or equivalent listing. I told the manager that these kinds of machines were being used all over the US and even in several places in Clark County. He sounded like we would have to work on getting that straightened out, but worst case, we could probably get some kind of provisional permit that would let the contractors start doing the work but would not allow us to actually operate the equipment.

I left the meeting optimistic that at least the work could get done but concerned about how to resolve the UL listing issue. The contractors had not wanted me to say outright that the machines weren’t UL listed, so the discussion on that point was hypothetical—how would we proceed if it turned out the machines weren’t listed, and so on. Basically, the answer seemed to be, talk to the manufacturers, who should know what to do. I had already started contacting them, though the questions had been about whether or not they had their equipment listed as opposed to figuring out what to do next.

More dead ends

I think it was still that same day that we got notified of the permits being denied, without even any provision for allowing some of the work to proceed. I talked to the manager again, who said he was not going to overrule a technical decision of his examiner: unless the machines were listed, there would be no permit. I told him the manufacturers did not know what I was talking about, and I pushed him for some kind of substantiation of how to proceed. These machines might be rare in Clark County, but it was inconceivable to me that their answer would just be, “You can’t use them, period.” This manager at the Building Department was always very polite and seemed kind and sympathetic to the frustrating absurdity of the situation: these machines were being used around town and all over the country, but I, trying to do things legitimately, was being prohibited from using them. He told me he would look into how I could possibly proceed.

He soon emailed me what amounted to a screenshot of OSHA’s NRTL page. While I was unclear on how that information would help me, the one hope it gave me was that I was now dealing with federal laws and directives, not some local ordinance. Now, the manufacturers would not be able to give me some run-around about not knowing the local laws, and there would likely be a lot more resources I could turn to.

|

Except that there weren’t. At least not ones that I could find, which is part of the reason I am posting about my experience. With the exception of one manufacturer, Heller, they still did not have any advice. The rep from Heller said that there was a UL-listed version of the oven available, which cost around $3k extra, and that they could exchange it for me at no extra cost. Still, that would have taken several months and involved re-crating and re-shipping a three thousand pound machine that was quite a hassle just getting unpackaged. I questioned their not having mentioned that option being available to me earlier, but they said it just didn’t occur to them since the vast majority of their customers get the normal version like I did. But even if I had exchanged ovens, I would still have been left with all of the other equipment, whose manufacturers and representatives were completely useless on this problem.

I also started contacting the Nationally Recognized Testing Labs (NRTLs) on that OSHA list. The list is actually pretty short, but if you click on those listings, you’ll see that the organizations tend to have many locations, followed by possibly hundreds of different standards to which they can certify a product. With neither the county nor the manufacturers giving me any guidance on what standards were applicable, it took days of calling around before getting to dead ends along the lines of, “we do not do field listings of that kind of machine”.

It was well into December, and I was starting to panic. I had hoped our old landlord would let us do a week or two extension, but they turned us down: if we were not out by the end of the year, we would be in violation of our lease and have to pay for all of January at some deadbeat rate that would have cost us almost $25k. With the holidays approaching, it would get more difficult to resolve the NRTL listing issue, and worst of all, I did not even have a specific next step to take. So I called Mr. Building Department Manager again, giving him the sob story of this potentially destroying a company with dozens of employees and imploring him to somehow direct me to some next step or a person who had some discretion and authority to help us out.

He had already been talking to his boss, Mr. Director, about our situation, and the only thing Mr. Manager could suggest was that I try talking to Mr. Director directly. Now, I do not know about the titles and hierarchies involved in the county organizational chart, and there are various modifiers like “deputy” that I am leaving out, but this guy was high enough up the chain of command that his name shows up on various Department letterheads, and he has his own secretary to keep people like me from bugging him too easily. She did a good enough job of it that after a day or two, I decided to go stake out his office in person.

Mr. Director’s office was in a different wing than Mr. Manager’s, but not having an appointment, the basic protocol of taking a ticket and waiting to be called on was still in play. After being called and variously explaining my situation and that I just wanted a few minutes of his time or to set up an appointment, the front office staff finally relented and let me talk to his secretary. Mr. Director was in a meeting, she said, but as she had told me on the phone, he would be in touch with me if appropriate. After pushing for something more definite or for just grabbing him after his meeting, she said I could try waiting. After maybe an hour, Mr. Manager appeared, apparently summoned by the secretary. We both knew he was the one that told me my only move was to get an audience with Mr. Director, so he just kindly confirmed that was the situation. I think he might have said something more to the secretary, though, because another half an hour or so later, I finally got to meet Mr. Director!

“I can’t remember everything you told me.”

At least it was worth it. Mr. Director, also very nice and polite, understood my situation and deadlines and indicated that I should go ahead without the permits. He did not say that, of course. But I am sure I understood him correctly. All of the words I am attributing to others here are just summaries, but I remember one thing quite specifically: when I asked him how I could proceed given that I had effectively notified him that I was about to defy the regulations, he said, “I can’t remember everything you told me.”

Despite the paranoid part of me wondering if I was getting set up, it was quite a relief to hear that from Mr. Director. The contractors had already been acting as if it would play out this way. Almost every contractor I had giving me bids recommended not getting a permit, and I heard from various vendors that it was standard operating procedure, even for major companies, to do the work first, get the permit later. With less than three weeks left in the year, there was no other answer. And though I understood that the conversation, which he could easily deny, gave me no formal or official protection, I was very grateful to him for making things clear.

I still pushed Mr. Director about a legitimate long-term solution, how to actually get the permits, and he helped me in an off-the-record way with that problem, too: he took me to some inspector, whom he told to give me a name and direct contact info for an NRTL representative that could help me. The total meeting time with Mr. Director was about 5 minutes. With the new information he gave me, I was able to proceed in parallel on getting the actual work done and on getting the NRTL listing. It took a little extra pushing to get installers to come out the week between Christmas and New Year’s, but we got the work done, the new machines installed, and our operation moved by the end of the year.

Getting the NRTL field listings

The direct contact the Clark County inspector had given me was for someone at Intertek, which according to Wikipedia is “the largest tester of consumer goods in the world”. They have a listing mark with “ETL” in a circle, which I had seen on our 3D printer when looking for listing labels on our machines. Working directly with the right person, who was familiar with Clark County, was much easier than trying to get somewhere starting from their main web page (though I am not sure if Intertek was one of the NRTLs I had gotten to a dead end with earlier). It was also nice to have a definite course of action, as opposed to most of my earlier interactions with the county and the machine manufacturers, which generally did not lead anywhere. Basically, I had to send the sales lady at Intertek a list of machines and their basic specs, and she gave me two quotes: one for their inspector to make one trip out here, and another quote for making two trips.

|

This brings me to one of the most frustrating aspects of this experience: I had no indication of how the inspection would go and what I was paying for. Was I paying for an inspector to fly out, look at our machines, and tell me, “These machines aren’t safe, so we won’t list them”? The idea behind the two-trip quote was that the inspector would come out, find some problems, we would then fix them, and the inspector would come back and verify that we had sufficiently addressed the issues. But what if the necessary changes required substantial redesigns of the machines? (Why would the Heller oven cost an extra $3k for the UL-approved version, and why would they bother with having two versions, if the required changes were minimal?)

I asked the Intertek sales lady about it. I understood that they could not know ahead of time what the state of our machines were, but if this is what they do all the time, surely they could tell me if they had approved a Heller 1707 Mark III oven before or what kind of modifications were required. But she wouldn’t tell me. So I decided to have them do one trip to inspect every non-trivial piece of equipment we have, even if it wasn’t really relevant to the Clark County building permits. At the very least, we could learn what kinds of things they checked, and I could hope to come away with some approved machines that I could show Clark County.

As I mentioned before, the 3D printer from Dimension Printing was the only special machine we had that was listed (more common machines, like printers, ultrasonic cleaners, the forklift charger, and small compressors were listed). So we had 16 machines inspected:

- Two laser cutters from Epilog Laser (24TT and 36EXT)

- Laser cutter from Beam Dynamics/Coherent (METABEAM 400)

- Laser cutter from Full Spectrum Laser (FSL 48×32-80W)

- Reflow oven from Heller (1707 Mark III)

- Reflow oven from Manncorp (R-500)

- Reflow oven from Dima (RO-0402)

- Three pick-and-place machines from Autotronik/Manncorp (MC-383, MC-391, and MC-392)

- Stencil printer from Autotronik/Manncorp (MC-1400)

- Two small conveyors we also got from Manncorp

- Chiller for large laser cutter from Polyscience

- 10 HP rotary screw compressor and dryer from Fiac/Werther (Silver D 10/300)

- Small chiller for Full Spectrum laser cutter, obtained through Full Spectrum

Getting all of this looked at in one trip cost a little under $10k; the two-trip alternative was over $15k. I had all the machine info to Intertek on January 3rd, the first business day of the year. There were a few delays because they wanted to see the machines fully operational (I won’t even go into that Catch-22), and with the way availability and scheduling worked out, the field inspector got out here the second week of February.

Field inspection

The inspector was here for four days. I did not interact with her that much, but I had one engineer with her the whole time to observe what she was checking and to address any issues. Unfortunately, thanks to a scam I’ll get to later, I cannot reveal what was on her checklist because she could not reveal it to us. The general order of inspections was from most critical equipment to least so that we could have a few days to address any important issues. Fortunately, everything went quite smoothly, with only minor modifications along the lines of adding warning labels being necessary. I asked her for her general impression of our equipment, and she said it was very nice; I guess it’s fairly routine for her to see really dangerous equipment.

|

I was most concerned with the Full Spectrum laser cutter and corresponding chiller since they are basically made and designed in China and cost substantially less than our other equipment. And, sure enough, it did have the most issues. Other than labeling, there were some issues with extra power outlets that are on the machine for convenience and that we were not using anyway; blocking them off and labeling them was all we had to do rectify the issue to the inspector’s satisfaction.

The most concrete safety-related thing I learned was about power cords. Most of our machines just run off 120V wall power, and they have power cords that look like regular computer power cords. However, while computer cords are allowed to be of a lower “SVT” rating, we have to use “SJT”-type cords, which apparently have thicker insulation. It’s possible some of our cords got swapped around during various moves, but the Epilog laser cutters were the only ones that had the appropriate cord type (this does not apply to the higher-power machines, which have special cords and plugs or are hard-wired to power). By the way, the power cords we ordered from Grainger, where I initially thought we would do an in-store purchase, arrived with Monoprice labels on them; Monoprice’s prices were less than half of Grainger’s.

The upshot was that within the first two days, we basically knew that we would get the labels on all 16 machines. All the machines passed grounding and insulation tests. We had to make only minor modifications that we could easily do ourselves. The inspector spent most of her last two days writing up her report, and she did indeed apply the coveted labels to all of our machines before she left.

Final report and back to the permits

I emailed the HVAC contractor that day to let him know the machines were all labeled. That somehow still was not enough for the county examiner, who I guess wanted to see the actual report. That took another three weeks. And then it took another week to get the permit. So, it was well into March before the contractors were technically even allowed to be starting the work. The contractors touched up some stuff to make sure it matched the permits and endured another few cycles and weeks of coordinating inspections and making trivial changes to satisfy the inspector. But finally, on March 21, we received final approval!

|

Lingering questions

This year’s IPC APEX EXPO, one of the electronics assembly industry’s biggest trade shows, was held at the end of February and beginning of March. Since this was after Intertek came out for the field evaluation but before I had the county permits, I attended with a different perspective than in years past. I was still trying to reconcile Clark County’s absolute insistence on the NRTL label, apparently backed up by OSHA, and the fact that none of my equipment manufacturers or their representatives seemed to know what to do. I have now spoken to dozens of people from various reputable manufacturers, and not one of them could tell me anything about getting an NRTL label. With the exception of the occasional exhaust filter or similar supporting equipment, I did not see NRTL labels on any of the machines. The closest I got was a few people vaguely recalling having heard of similar problems in some specific cities or counties in California.

|

On the other hand, TUV Rheinland and UL had booths at APEX. I did not see the UL booth, but I stopped by the TUV booth, which I normally would not have noticed among the much more exciting exhibits filled with big machines. The guy manning the booth said he had anecdotally heard of local governments ramping up enforcement of field listing laws. I came away with the impression that it would have cost about the same amount to have gone with TUV and that a starting point to fly someone out for a minimal visit would probably run around $2500. I pressed him on this issue of publicizing which machines had been field labeled by them in the past to give future customers some idea of whether or not a machine was likely to be problematic, and I got one slightly believable explanation of why they also do not do that: A large part of these NRTLs’ business is to do extensive product testing and for the resulting listing to cover all instances of a tested product; maintaining public lists of products that had passed much less stringent field testing would effectively dilute the meaning of the main listings and also possibly expose the test labs to liabilities from someone misconstruing the meaning of a product appearing on a less stringent list.

I left APEX still bothered by this disconnect between the manufacturers and the testing organizations. The manufacturers of the equipment we use have generally given us good support, and they had already made the sales, so they had nothing to gain by lying to me if they actually knew about these field listing requirements. The same applies to exhibitors at the show; and, if any of them did have general listings or specific knowledge of their machines passing field inspections, it would give them a competitive advantage to publicize that.

Contributing to my unease about how this permit process went down is that it played out in the general format of a corrupt kickback scheme: government official blocks a project with little justification, government official confidentially directs applicant to third party, applicant pays third party a bunch of money, and government official unblocks the project. I don’t really think anything that unethical happened in my case, and I think the only reason Clark County did not publicly direct me to Intertek right away was because they were trying not to endorse one company over another.

That still leaves me wondering why getting the permit was much harder this time than in the past and involved steps so many relevant parties were unfamiliar with. Did the laws or enforcement of them change significantly since 2009? Was there some project size threshold that I exceeded this time, putting us under a higher level of scrutiny? Did I just happen to get tripped up by an overzealous inspector who had the discretion to allow this to play out differently? Was there some preexisting conflict between the examiners and one of my contractors, or were the contractors just particularly incompetent?

In my early conversations with Mr. Manager, I asked him some of these questions. The main answer I got was that perhaps my earlier permit was not as valid as it could have been since the equipment getting connected was not specified; in this instance, they would not allow that to happen. No one at the Building Department said anything to call into question the competence of the contractors, and I think I gave them ample opportunity for that. I don’t really know how good the contractors were, but in the case of the electricians, I could at least judge some of the basic electrical theory they sometimes let slip out, and the company I went with was the best of the ones I had interacted with. The contractors were not ones I had used before, but they were referred by reputable sources like previous landlords. In general, my impression is that construction-related companies in Las Vegas have been hurting, and I hope that surviving the downturn is an indication of at least some basic competence. The actual work they did was fine, as far as I can tell.

A large part of my frustration came from not knowing what the laws were. It would have been nice if the county officials had directed me to something specific, but they did not seem to be bothered by having to actually know what the laws were: they knew I needed a label, and they gave me no way of confirming that. With all kinds of information available online, I had become accustomed to laws becoming more and more accessible, so the lack of references was especially conspicuous. And that brings me to the scam I mentioned earlier about the Intertek checklist we couldn’t see.

Secret laws

It turns out that the US has many secret laws you and I cannot just look up and read. Organizations like UL put a bunch of effort into developing various standards, and they then want to charge a lot money to use those standards. For the government, it’s convenient to just use those standards. Unfortunately, the result is that the private standards become required by law, but looking at those standards, and by extension the laws, still requires paying the organization that made them.

|

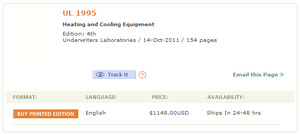

I don’t know how the standard creator’s monopoly plays into this, but the fees are very high and the licenses restrictive far beyond what I suspect is most people’s notion of fair use. One standard that applied to us cost over $400 for a PDF file; I did not find a good site I could link to directly for the PDF downloads, but Intertek directs to a site that only has printed versions such as UL 1450 for compressors for $1,032 and UL 1995 for heating and cooling equipment for $1,148. I have seen requirements for a copy per person that looks at it, and if I buy a copy for an employee and he leaves the company, I would have to pay again to let his replacement look at it. I do not know how enforceable these terms are, but the licenses also restrict derived work, such as the Intertek inspector’s checklist, and she cited that licensing restriction as the reason we could not even look at her checklist.

It’s startlingly un-American that in a world with more and more access to free information, something as fundamental to basic justice as showing fellow citizens the laws is illegal.

Ramifications for small businesses and manufacturers

Some might view this post as excessive whining about what amounts to dealing with the government. While I am sure that many businesses and individuals have much worse experiences, that doesn’t mean we shouldn’t try to spread awareness of specific problems. Perhaps some of the government employees I was working with at the Building Department could have given me more leeway than they did, but overall, they were very polite, professional, and even kind; I believe that for the most part, they were merely executing the orders and policies set in place by higher officials and the general public.

|

With the recent recession and general weakness of the US economy, there has been a lot of public hand wringing about American competitiveness in general and about the future of American manufacturing in particular. Having a strong local manufacturing base has significant implications for innovation, and while that might be most evident with large manufacturers and the latest technology, I think the general principle applies to small manufacturers like Pololu as well. Politicians often want to help manufacturers by adding more regulations and more special cases when the problem is the government getting in the way in the first place. A tax break on new equipment cannot help us if the local government does not let us install it.

In this case, the permitting process ended up just costing me a bunch of time and an extra ten grand, which isn’t going to break the company. But the reason I can even say “just” about that high of a cost is that the alternative of shutting down production for three months until we had the necessary permits could have done huge damage to the company, and I still do not know of a legal way to avoid that drastic scenario. The field labels we have on our machines apply only to their current location; if we move, we need to get an NRTL out again to inspect them. My hope is that in a future move, the county inspectors would be reasonable enough to use the existing NRTL labels to permit work to be done at a new location before the equipment gets moved there, but the inspectors should not have to bend the rules to allow that.

Similarly, a small business (or any entity) should not have to make the decision between possible destruction and breaking the law when it is doing nothing wrong. A just society should not put basic existence in conflict with conforming to the law, and we should not accept a legal framework in which everyone is a criminal. Yet the reality, as with traffic laws and speeding, is that everyone is constantly breaking the law. This in turn opens the door to actual crimes, like extortion and blackmail. While such problems affect everyone, small businesses in particular are less likely to have the resources to defend themselves if the government decides to come after them.

The current regulatory framework also hurts small businesses that make machines subject to the NRTL listing requirements. Spending $2,500 for a field listing trip is probably not going to hurt a $200,000 machine sale, but it is much more likely to impact a 3D printer that costs under $2,000, such as the offerings from MakerBot Industries. I suspect these do not have the general listing like our $40k 3D printer and all kinds of consumer products, so if we at Pololu wanted to get a MakerBot, we would be facing the choice of operating the machine illegally, as I suspect most organizations using MakerBots do, or paying more than the cost of the machine to make it legal. This unpalatable choice at least partially contributes to our tending toward the third route of just not getting a MakerBot, which, assuming it’s a useful machine, hurts both Pololu and MakerBot.

Safety

This post would be incomplete without some mention of safety, which I suspect starts out as the primary motivator of America’s burdensome regulatory environment. With every new disaster, whether real or a merely a circumstance perceived as such, someone with corresponding interests calls for more laws and regulations. When the calls come from those sincerely wanting to improve safety, I think they miss three important points:

- Safety should not trump all other considerations.

- Organizations desire safety independent of government requirements for it.

- Government regulations frequently reduce safety.

“Safety first!” is easy to say, but unless you spend your entire life in your house wearing a helmet, you probably do not actually put safety first. As with most engineering problems (and life in general), running a viable organization requires trade-offs and finding an optimal balance among competing interests; therefore, it will always be easy to point to any safety-related policy or decision and demonstrate that things could be safer. Part of life is assessing risks and potential rewards, including enjoyment and happiness gained from doing something dangerous; free people should be allowed to make those choices for themselves. Ben Franklin’s quote about those who give up liberty for safety deserving neither, which I hear often in the context of national security policy discussions, applies just as well to everyday safety issues.

Because nothing is ever as safe as it could be and because businesses have to prioritize all kinds of things over minimal safety improvements, it’s easy to vilify them as greedy or uncaring. But the reality is that most businesses care about themselves without the government forcing them to. A landlord will want to make sure his tenant is not doing anything that will make it overly likely for the building to burn down. If it’s a small business, it’s quite likely that an owner or someone very important to him is constantly involved with the machinery, and they do not want to get crushed or electrocuted. Manufacturers want their products to be safe enough whether required by law or not, just like they want them to be of good enough quality and a good enough price. Examples of companies really not caring about safety are actually rare and contrived, and those who do not care enough will eventually get weeded out.

Finally, it’s important to be aware that government intervention frequently reduces actual safety. From a theoretical standpoint, it should be clear that the lack of transparency in the laws reduces safety. Would you take a new company safety initiative seriously if everyone was actively discouraged from knowing the safety policies? But even in everyday, practical ways, the government actively undermines improvement in safety.

I have two immediate examples. The first assumes that the building inspectors are actually useful (which I think they can be); in that case, the difficulty in obtaining a permit prevents many projects from getting inspected at all. My contractors could have done something really unsafe, and the building could have burned down before the county ever issued a permit. If they had some better approach, they could have at least permitted and inspected the contractors’ work while leaving the machine inspections to the NRTLs.

A more damning example has to do with our fire alarm system, which has one actual noise-making alarm that is not loud enough to cover the entire building. There is no doubt that adding some more sirens would be technically simple and would substantially improve the effectiveness of the alarm and therefore probably improve safety. But, you guessed it: we are not allowed to do that. (Having more than one alarm would put the building in some other class, which would then require all kinds of other things in the building to be overhauled, or something like that. One fire inspector suggested maybe we could put some baby monitors around the alarm.)

A last point I’ll mention is that government intervention reduces safety in the standard way any nanny state weakens its citizens: it creates a false sense of safety and makes people less vigilant and aware of their own circumstances and choices. Safety becomes something that is out of their control rather than something they should constantly be monitoring.

*****

Well, if you read this far, it’s probably because some of what I wrote about is relevant to your life. I hope there is something useful here. I would appreciate any comments you have on the topics I raised, whether it’s just bitching about similar hassles you’ve experienced or if you have specific advice on how I should handle permitting issues better in the future.

17 comments

I don't feel like you're whining at all. It's no wonder that SMBs act (or simply don't start) the way that they do. Your frustration seems more than justified and just reinforces the "rules are for suckers" mentality.

Glad to see that you didn't end up having to hand out fast-food applications to employees as part of their outplacement assistance package.

Thank you very much for the informative and well-composed post.

Unfortunately my side project will also have interaction with the city for various permits over the next few months :-/

If we had to come up with $10k just for some permits, I don't know how we'd do it as just a starting non-profit community hackerspace!

Glad you guys made it through it in the end, it had to be a very frustrating journey.

FWIW, Carl Malamud has done wonderful things with some civic codes over at https://public.resource.org/ .

I worked for a local government and each of our inspectors had their own list of what they looked for. Each time a facility was reinspected or set of plans was reviewed, the owner was given a completely differnt list of what the inspector was looking for.

When we had a new building built, I kept pointing out the electrical code violations to the inspector, as I was verifying data-com cabling, and his response was that he never went on a ladder of got down on his knees to inspect something. So the electrical issues I pointed out, he would have never found and some were big fire or life/safety issues in the building he was going to move into for the new building inspection offices. Have a great Day.

I agree that the lack of transparency is frustrating. I'm wondering what requirements your insurance company needed with regards to these equipments. Perhaps they could have pointed you to what's needed sooner.

Thanks for that perspective. I am generally in favor of leaving room for discretion, but that leads to more room for abuse because of the government's monopoly. If we instead had private inspections (which the county basically deferred to, anyway), there would be a little more room for alternatives if one particular inspector were being unreasonable.

- Jan

I am not suggesting that "qualified and accountable" people should not be involved. However, I think that government should not have a monopoly on safety standards and that the existing government monopoly leads to sub-optimal results (just look at the post above yours for an example). For instance, we could have facilities rated by some private company, and employees could choose whether to work in a place that was not rated or had a lower rating than they were comfortable with. Your insurance example shows yet another way the private market incentivizes safety. (And doesn't your suggestion of going to the insurance company indicate that you think the private company might have been more effective than the government?)

- Jan

I am sorry for what you have went thru, and my hat off for your persistence. And thank you for sharing your story!

Electrical code enforcement for commercial enterprises can be exasperating, but, I think the issue you got snagged by is that the licensing of Electrical Contractors has changed since you had your prior building checked out.

As I understand it, Electrical Contractors are required to have a Master Electrician, and the Master's license is the one at risk if something goes wrong. This tends to make electricians a little more concerned about the rules then they used to be, where they were just risking a ding on the company's contractor license, it also means Electrical Contractors, who are not actually Master Electricians are at the mercy of their Master Electricans (how I learned this is a buddy was working a shop where the Master left, and they couldn't work until the owner either passed certification, or hired a new Master)

Codes come from the time when unsafe businesses burned down entire blocks. This still happens in places like China. If all US businesses had the integrity of pololu.com then all these rules wouldn't be needed for public safety. But history shows it only takes one corrupt utility to poison an entire city. ..

Thanks for sharing!

I don't really understand your first paragraph. Has someone like UL lobbied for the status quo? (And even if they did, I would object to the implication that it is their fault, as opposed to that of a government that will not disclose its own rules.)

I think the rest of your comment is predicated on some common assumptions that I suspect are not valid, so I'll just mention a few of them for each sentence:

"Codes come from the time when unsafe businesses burned down entire blocks."

* Safety is not binary.

* Safety was improving before and without government intervention.

* New codes are constantly being added.

* Some codes (e.g. that fire alarm thing) specifically prevent us from being safer.

"This still happens in places like China."

* Fires and other accidents still happen here in the US.

* Regading "entire blocks", are you referring to some specific recent incidents in China?

"If all US businesses had the integrity of pololu.com then all these rules wouldn't be needed for public safety."

* I appreciate your trust in our integrity, but I don't think that's a significant factor in our trying to do things well.

* Our "integrity" mostly comes from caring about our stuff, which I think most owners do.

* If you agree that the vast majority of businesses are safe enough out of their own self-interest, how much do you want to shackle them because of a few bad apples?

"But history shows it only takes one corrupt utility to poison an entire city."

* Can you point to specifics?

* Utilities in the US are so intertwined with government that I suspect instances of examples of bad behavior are more an indictment of government than of private business.

* Like safety, "poison" is not binary and tends to be used unfairly to incite emotional responses. There is a continuum to the tradeoffs between benefits a community gets from services provided by the utility and negative side effects like pollution.

* Utilities are a more difficult case, and it's somewhat unfair to bring that up in a discussion like this about codes. I'm fine with a lot of these rules existing and the processes for them as long as they apply only to public entities since the public is the owner or payer for those organizations. But private organizations should have way more latitude in their own policies.

More generally, the underlying premise of your post is that the codes are for some "public safety" kind of thing. But most of them, at least the ones I am writing about here, are about protecting individuals, who should be free to make decisions for themselves. Why should we be subject to rules intended to prevent "entire blocks" from burning down if there are no other buildings around us?

Lots of people want some kind of "regulation". I'm not sure if that's valid, but I think it's definitely invalid to assume that some detached bureaucrat will do a better job of it than a private owner.

- Jan

These issues with the hidden rules extend far beyond electronics, too; the standards for building code are hidden behind paywalls, so if you need to know specific information to do anything safely not outlined in the code book, you're screwed.