This is a merged information page for Item #2455.

View normal product page.

Pololu item #:

2455

Brand:

Pololu

Status:

Active and Preferred

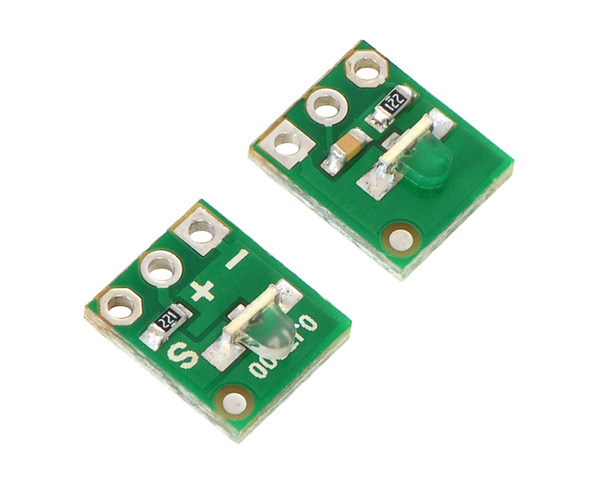

The QTR-L-1RC reflectance sensor incorporates a right-angle infrared LED and a right-angle phototransistor in an inexpensive, tiny 0.35″ × 0.3″ module that can be mounted almost anywhere and is great for edge detection and line following. The output is designed to be measured by a digital I/O line. This sensor is sold in packs of two units.

Compare all products in Older QTR Sensors or

Compare all products in Older QTR Sensors or  Single-Channel QTR Reflectance Sensors.

Single-Channel QTR Reflectance Sensors.

|

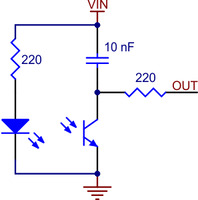

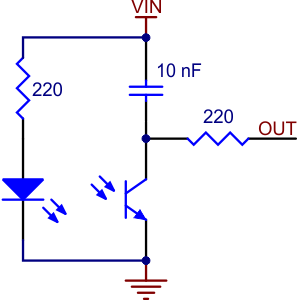

QTR-1RC and QTR-L-1RC reflectance sensor schematic diagram. |

|---|

|

QTR-L-1RC reflectance sensor on a quarter next to a QTR-1A reflectance sensor. |

|---|

|

QTR-L-1RC reflectance sensor emitter and detector sides with labeled pinout. |

|---|

|

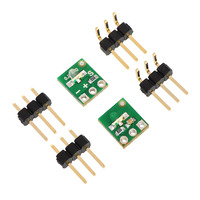

QTR-L-1A or QTR-L-1RC reflectance sensor (2-pack) with included header pins. |

|---|

|

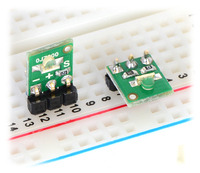

QTR-L-1A and QTR-L-1RC reflectance sensors plugged into a breadboard in two possible orientations. |

|---|

Note: The QTR-L-1RC reflectance sensor requires a digital I/O line to take readings. The similar QTR-L-1A reflectance sensor is available with an analog output.

|

The Pololu QTR-L-1RC reflectance sensor carries a right-angle infrared LED and a right-angle phototransistor, both pointing toward the front edge of the board. To use the sensor, you must first charge the output node by applying a voltage to the OUT pin. You can then read the reflectance by withdrawing that externally applied voltage on the OUT pin and timing how long it takes the output voltage to decay due to the integrated phototransistor. Shorter decay time is an indication of greater reflection. This measurement approach has several advantages, especially when multiple units are used:

The LED current-limiting resistor is set to deliver approximately 17 mA to the LED when VIN is 5 V. The current requirement can be met by some microcontroller I/O lines, allowing the sensor to be powered up and down through an I/O line to conserve power.

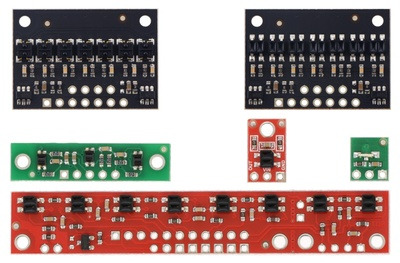

This sensor was designed to be used with the board perpendicular to the surface being sensed, and narrow-angle lenses built into the infrared LED and phototransistor packages allow it to be effective to a range of about 1″ (25 mm). Because of its small size, multiple units can easily be arranged to fit various applications such as line sensing and proximity/edge detection. The QTR-L-1RC is sold in packs of two units.

For a similar sensor that can be used with the board parallel to the surface, but with shorter range, please see the QTR-1RC reflectance sensor. We also offer arrays of three and eight sensors: the QTR-3RC reflectance sensor array and the QTR-8RC reflectance sensor array.

|

QTR sensor size comparison. Top row: QTRX-HD-07, QTR-HD-07; middle row: QTR-3, QTR-1, QTR-L-1; bottom row: QTR-8. |

|---|

|

Like the Parallax QTI, the QTR-L-1RC module has sensor outputs that require a digital I/O line capable of driving the output line high and then measuring the time for the output voltage to decay. The typical sequence for reading a sensor is:

These steps can typically be executed in parallel on multiple I/O lines.

With a strong reflectance, the decay time can be as low as several dozen microseconds; with no reflectance, the decay time can be up to a few milliseconds. The exact time of the decay depends on your microcontroller’s I/O line characteristics. Meaningful results can be available within 1 ms in typical cases (i.e. when not trying to measure subtle differences in low-reflectance scenarios), allowing up to 1 kHz sampling. The following table shows some typical decay times (from 5 V down to a 2 V threshold) of the sensor over different surfaces and at different distances:

| White surface | 3/4″ black electrical tape | |

|---|---|---|

| 0.25″ distance | 100 μs | 320 μs |

| 1″ distance | 160 μs | 260 μs |

Ambient light, especially sunlight, can affect the sensor readings significantly. If the decay time of the QTR-L-1RC is consistently low, you might need to add shielding around the sensor or mount it in a different location to reduce interference from outside light sources.

Our Pololu AVR library provides functions that make it easy to use these sensors with our Orangutan robot controllers; please see the QTR Reflectance Sensors section of our library command reference for more information. We also have a Arduino library for these sensors.

Each pack of two reflectance sensors includes sets of straight male header strips and right-angle male header strips, which allow you to mount them in the orientation of your choice. You can also solder wires, such as ribbon cable, directly to the pads for the most compact installation.

|

|

With only five components, the operation of this sensor is relatively basic. The emitter side is just an IR LED with an appropriate current-limiting resistor. The light from the emitter leaves the sensor, reflects off a nearby surface, and returns to the detector.

The detector side is a resistor-capacitor (RC) circuit, where the resistance comes from the phototransistor and is a measure of the incident infrared light, and the decay time is proportional to the resistance. The first step of the sensor-reading process—driving the sensor output high—discharges the integrated 10 nF capacitor and puts both sides at the same voltage (VIN). Alternatively, you can think of this as “charging the output node”, and it is functionally equivalent to charging a capacitor with one side connected to ground. Once you are no longer supplying an external voltage to the output pin, the capacitor can slowly charge through the phototransistor, with the rate of charging being a function of the phototransistor’s resistance (which is in turn a function of the incident IR). As the capacitor charges, the voltage on the output side drops, eventually reaching zero when the capacitor is fully charged. Alternatively, you can think of this as “discharging the output node”, and it is functionally equivalent to discharging a capacitor with one side connected to ground.

The 220 Ω resistor on the OUT line serves to limit the current flow, making it possible for a microcontroller output to safely charge the output node prior to each reading. It has very little effect on the sensor output.

|

|

| Other PCB markings: | 0J7200 |

|---|

Information about using the Pololu QTR reflectance sensors, including differences between A-type and RC-type sensors and sample oscilloscope screen captures of sensor outputs.

Information about installing and using the C/C++ libraries provided for use with Pololu products.

A reference to commands provided in the Pololu C/C++ and Arduino libraries for the AVR.

Step-by-step instructions for building your own line-following courses.

This DXF drawing shows the locations of all of the board’s holes.

Un guide utiliser et exploiter un senseur QTR (détecteur de ligne) (version 0.1). Note: This French translation of our QTR sensor documentation was made by our distributor MCHobby.

Matthew Phillipps ported our Arduino Library for the Pololu QTR Reflectance Sensors to the mbed platform. The Arduino library is designed to work with Pololu QTR reflectance sensors, so the mbed library should too, but Matthew points out he only tested it with the analog sensors. This library was not written and is not maintained by Pololu.

This library for Arduino makes it easy to interface with Pololu QTR Reflectance Sensors.

No FAQs available.

No blog posts to show.