Pololu Blog » User Profile: Jan » Posts by Jan »

Posts by Jan (Page 5)

You are currently viewing a selection of posts from the Pololu Blog. You can also view all the posts.

Popular tags: community projects new products raspberry pi arduino more…

Purchasing electronics components in America

|

I am a little proud (but mostly embarrassed) that I still do basically all of the electronics component purchasing for Pololu. Today I am writing about buying components because their prices have a huge impact on the end price of our products, especially when we work to cut down other costs as I have been discussing lately. Buying parts when trying to compete globally is more frustrating than you might think, and I hope that writing this will help trigger some conversations that will help us do better and also encourage component manufacturers and distributors to better support small electronics manufacturers in the United States.

I buy almost all of the electronic components that go into our products from suppliers in the United States. That includes integrated circuits, discrete semiconductor products like transistors and diodes, resistors, capacitors, inductors, and so on. The only parts I do not buy in America are components like connectors and electromechanical devices like switches and buzzers. This post is mostly about buying components in the US from US suppliers, but I will briefly touch on the non-US components to provide some background and comparison.

|

There are two main reasons for those non-US components: they are much cheaper than similar parts in the US and we can evaluate that they are good enough. That second reason is important because counterfeits and fake parts are a big problem in the electronics industry. We can look at something like a 0.1" male header or an electromagnetic buzzer and see basically what it is. Once we can be confident that a component or supplier is good enough for the level of performance and reliability we need from our products, we can look at prices to see whether it’s worth the extra hassle (and that amount of hassle keeps going down) to get the components overseas, which pretty much means China (and Taiwan, in case that distinction is meaningful). And that price difference can be huge. When I started getting connectors directly from Taiwan over ten years ago, the price difference was approaching a factor of ten, meaning that for around a thousand dollars I could buy what would cost me ten thousand domestically. Some of the price differences seem to be getting smaller, but the components still seem to be easily three to five times cheaper in China. Early on (around 2005), local salespeople would ask me what prices I was getting in China, thinking they had some better deal or connection than I knew of; nowadays, they don’t even ask or try to compete.

With all the other component types, even for the most basic parts like resistors and capacitors, we are not really qualified to evaluate them, and I would not want to be responsible for doing quality control for millions of units even if we could analyze one particular instance of a resistor or capacitor and conclude that it is good enough. So, I only buy components from reputable brands through their authorized distributors, which means I buy basically all our components through American companies (with one exception I’ll get to soon that almost doesn’t feel like an exception, anyway). Those companies also tend to be the biggest electronic parts distributors in the world.

I still buy some components from the catalog-type sources that are probably familiar even to most students and hobbyists, like Digi-Key, Mouser, and Newark. Once upon a time, these companies printed large catalogs that were the best way to find out what kinds of components even existed (especially when I was growing up in Hawaii). Digi-Key stopped printing catalogs a few years ago; Newark apparently still does. In any case, these kinds of sources now have good online resources for finding parts, they tend to have a lot of parts in stock, and they are set up for small quantities, which is why they are great resources for individuals, too. Usually, it’s very easy to buy components from these sources, and I rarely interact with anyone when I do since I usually just place the orders through the web sites at their listed prices.

|

However, the prices usually are not the best at those most convenient sources, especially when my minimum quantities tend to be full reels with thousands of parts rather than a few individual parts. So for most of my electronics purchasing, I go with big distributors like Arrow, Avnet, and Future Electronics. These companies have local offices (though for Las Vegas, “local” tends to mean in Phoenix, Arizona or somewhere in Southern California) that have salespeople that I can talk to that can help me get lower prices. Future Electronics, being a Canadian company, is the exception that I mentioned earlier; but, working with them is basically the same as working with Avnet or Arrow since they have the local staff and things like a distribution center near Memphis, Tennessee (here is a video about it).

Back when I was a student and before I started Pololu, I thought electronics distributors just bought components from manufacturers and then sold them with some markup on their cost. I think some of that did happen and still happens today, but it’s less common and less practical now because there are so many different, specialized components that they cannot all just be sitting in stock somewhere, waiting for the unlikely scenario that someone would come along and buy them. When I buy from distributors like Digi-Key and Mouser, I am almost always buying something they have in stock; when I buy from Arrow and Future, it’s almost never something they have in stock (or it’s something they have in stock because they had good reason to expect me to order).

But there was a much bigger misconception in my naive view than just the timing of when a distributor bought some parts relative to when the end customer ordered them. The major thing I learned in the early years of running Pololu is that component manufacturers charge the distributors different prices for the same components, based on the end customer! In some ways, that’s frustrating because it means I have to do a lot more work to get a good price. I have to convince each distributor and each manufacturer to give me a good price, and sometimes I have to do that with each component. It can also be a good thing in that if I do establish a good relationship with some manufacturer and distributor, the hassle per part goes down over time as they get to know our business and what factors are important to us. And some of them probably do give me a globally competitive price sometimes.

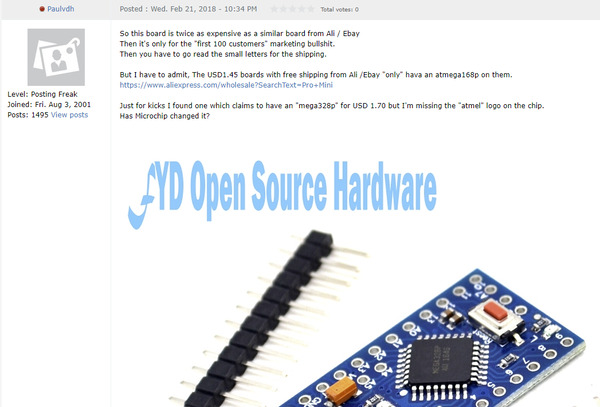

The difficulty, and what prompted me to write this post, is with those manufacturers that do not. (That or counterfeits, which is sometimes the explanation or excuse I get back from manufacturer’s representatives.) Well, the really specific thing that led me to write this post is the AVR Freaks thread about my last post, in which I introduced our new A-Star 328PB Micro:

|

AVR Freaks post about A-Star 328PB Micro announcement, the motivation for this blog post. |

|---|

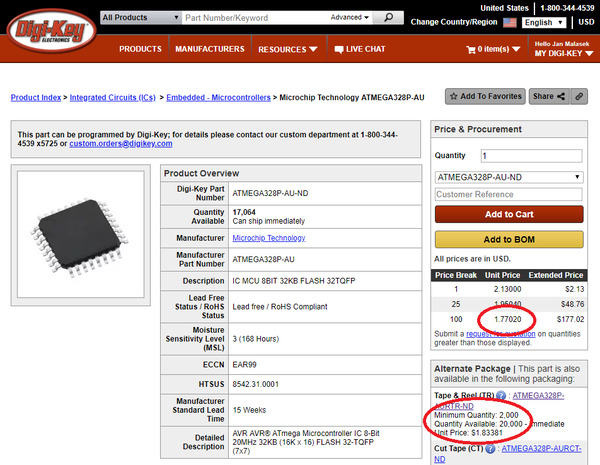

The poster mentions a board similar to Pololu’s with an ATmega328P for $1.70 (and wonders about the chip authenticity). I went to look at the part price on Digi-Key, and this is what I saw:

|

Screenshot of Digi-Key price for ATmega328P with prices highlighted, retrieved 25 February 2018. |

|---|

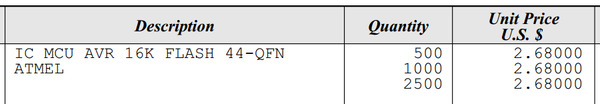

I have highlighted the relevant fields, which are the lowest prices: $1.77 each at 100 pieces, and alternately, on a reel of 2000 pieces for $1.83. 100 pieces is kind of low for a highest price break. A long time ago, I tried out the higher volume quote request option that is suggested under the 100-piece price, and after some back-and-forth, Digi-Key gave me an official volume quote for higher quantities with the exact same price as at the 100-piece break:

|

Excerpt from quantity price quote from Digi-Key (from around 2010) |

|---|

I tried it a few more times with some other parts, but it was basically the same result every time, so I have not tried special pricing with Digi-Key since. That was close to ten years ago, so maybe it’s different now, and maybe it would be different if I had asked for 10k or 100k pieces.

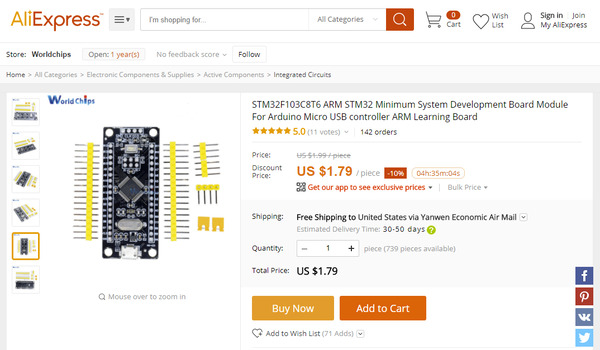

Back to the original point: you can get the whole assembled board from China, in single-piece quantities, for less than the price of just the one component, even in volume quantities. And this Atmel/Microchip example is far from atypical or anywhere near the worst case. Here is an AliExpress listing for a small development board for the STM32F103C8T6 microcontroller:

|

AliExpress listing for an STM32F103 development board for $1.79 including shipping, captured 25 February 2018. |

|---|

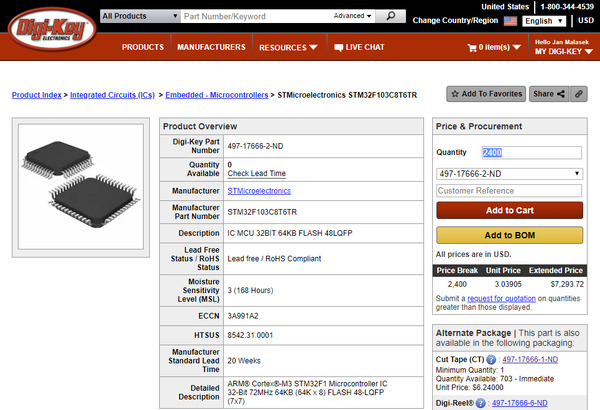

In this case, Digi-Key has prices listed for higher quantities than in the earlier example, and the 2400-piece reel has the best unit price of $3.04:

|

Screenshot of Digi-Key price for STM32F103C8T6, retrieved 25 February 2018. |

|---|

I have been working on pricing for similar STM32 parts, and even at twenty thousand pieces (not through Digi-Key), they are not getting to the prices of just one of these complete boards, with double-sided assembly and a bunch of additional components (and free shipping!—though that is some separate scam that I do not blame the electronics component manufacturers and distributors for). Something clearly doesn’t add up, right?

|

As I mentioned earlier, some manufacturers will say the parts in the cheap boards from China are counterfeits. I believe that is the explanation in some cases, and we have our share of frustrations with knock-offs and counterfeits of our own products. But I had one experience around five years ago that makes me very skeptical that that is anywhere near the whole story. One of our more successful early products, at least by number of units sold, was a basic carrier for Allegro’s A4988 stepper motor driver. I remember being frustrated because Allegro seemed to have some deal in place with Digi-Key that gave them the best prices (and unlike the examples above, Digi-Key did have volume breaks up to many tens of thousands on that part). Digi-Key has been getting better on prices, but still, paying “Digi-Key prices” seemed like an insult when I was buying tens of thousands of these parts at a time.

It became more of a problem when the knock-offs of our boards started appearing on eBay and other sites for basically the same prices as just our component costs. I kept trying to get my suppliers to help me with my prices until I got the parts from Asia via Future Electronics. They assured me these were genuine parts through their global partners or subsidiaries, and they could do that for me because they were not authorized distributors for Allegro in the United States. So, that alone was a good indication that these parts were out there, through reputable sources, at lower prices than I could get in the US. But the conclusion to this story gets better: someone who could do something about it at Allegro finally got word that I was getting these parts elsewhere (they noticed the sales abruptly went away, and they wanted to see my invoices from other vendors) and reduced my authorized price, through Arrow, to almost half of what it had been.

This was over the course of maybe two years, and while it did help and we lowered our prices, I believe we missed out on a lot of potential sales because it took so long to get the prices down. The sad thing is that there are probably many more missed opportunities, not even just for Pololu, because of how components get priced in the US. The manufacturers seem more willing to cut prices after demand is proven and they start losing sales rather than up front to make the sales happen in the first place. And to be clear, I am not talking about small quantities like broken reels and cut tape that require extra handling and processing. I also understand that these modern 32-bit microcontrollers like the STM32 are such amazing achievements that it seems really unappreciative to complain about one costing $2. It’s just that when the same parts are costing one dollar somewhere else, we need to figure out how to get that price if we want to be globally competitive with our products.

Since I know many of you are also interested in open-source hardware, I should mention the ramifications component pricing has for openness with our designs. One of the factors that goes into how much information we release is how good I think our component price is. It’s easier to share key components that we use if I think we can keep making our products competitively.

Back to some of the comments that led me to start writing on this topic. I hope I have shown you a different kind of behind-the-scenes view than just the machines that go into making our products. Some of that “twice as expensive as a similar board from Ali / Ebay” goes all the way down to the basic component level. I hope you can see that I am working on addressing that. I would be interested in what other small manufacturers in America (and in other countries besides China) do. Should I just start sourcing more components from China? Should I be using smaller distributors in the US? (I am skeptical that would make a big difference because of my understanding that manufacturers are basically setting the prices). Or is there something else I’m completely missing? I know some of you who read my posts work for the electronics manufacturers and distributors; can you help push for getting better component pricing in the US? For all of you who like making electronics, wouldn’t it be nice to have the option (or for your kids to have the option) to do that without having to live in China or being limited to industries like aerospace and military where components costs might not matter as much?

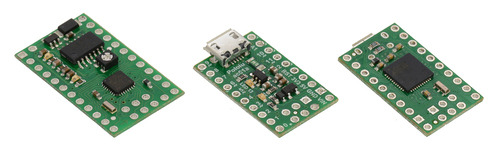

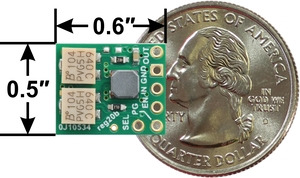

New product: A-Star 328PB Micro

Today we are releasing our newest A-Star programmable controller, the A-Star 328PB Micro. It is basically our version of the ubiquitous Arduino Pro Mini type products, but with the newer ATmega328PB microcontroller. The board itself is pretty straightforward (though the updated AVR is exciting), so the main thing I want to share in this post is our history with the Atmel ATmega328PB microcontrollers (this was before Microchip acquired Atmel) and how this product would not have existed without our lower-cost manufacturing initiative that I have been discussing.

We have been using the ATmega8, and then the ATmega48, ATmega168, and ATmega328P, since 2004 in many of our user-programmable products because of their versatility and excellent free compiler support (which also made Arduino possible). We first heard about the ATmega328PB in early 2014. The product kept being delayed, and I did not get a quote for them until October 2015. I ordered a reel right away; it arrived in March 2016. Over those two years, we put our AVR-related efforts into the ATmega32U4, releasing several A-Star 32U4 programmable controllers and using it on robots like the Zumo 32U4. The ATmega32U4 was a superior part with native USB and more I/O lines, making it a better fit for many of our applications. By the time we finally got the ATmega328PB parts, we had the A-Star 32U4 Micro available for just $12.75, making it less exciting to put effort into a lower-performance product that might end up costing almost the same amount.

|

Original ATmega168-based Baby Orangutan robot controller from 2005 (left) next to A-Star 32U4 Micro boards. |

|---|

The new manufacturing equipment I ordered in the fall of 2017, along with the availability of our latest AVR programmer, brought attention back to the feasibility of a basic ATmega328PB carrier. I was hesitant to put effort into a product where we could not offer something substantially more compelling than what was already available. Despite the ATmega328PB being out in the wild for almost two years, it still had not really made it into many Arduino products, so I thought that perhaps we could offer something there. But more importantly, I wanted to see how low we could price it. I was aware of Arduino Pro Mini clones available on eBay and the AliExpress-type sites for under $3. Most official Arduino Pro Mini type products cost more like $10. For this project to be worthwhile, I wanted to get under $5.

It turns out we had to squeeze quite a bit just to get to the upper limit of that “under $5” goal, and so we are releasing this product at a unit retail price of $4.95. It’s not the under-$3 you can find for the absolute cheapest clones, but if you get the A-Star 328PB Micro from us, you are getting a well-supported, well-made product (each unit is 100% automatically visually inspected and 100% functionally tested) and supporting a company that is doing more than just copying products that are already out there.

It is my hope that by being able to offer the A-Star 328PB Micro for under $5, we are offering something meaningful, giving you a new option for general-purpose controllers at the price of a cheap lunch. I am interested to hear what you think. Is the 328PB interesting when you can get USB for not much more? Is the price low enough for you to buy from us instead of getting it from China?

We are offering the A-Star 328PB Micro in four voltage and frequency combinations:

- 5 V, 16 MHz (blue power LED)

- 5 V, 20 MHz (red power LED) Note: See item-specific page for speed warning.

- 3.3 V, 8 MHz (green power LED)

- 3.3 V, 12 MHz (yellow power LED)

|

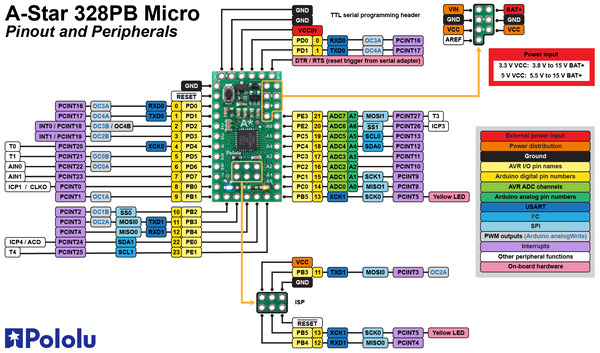

A-Star 328PB Micro pinout diagram. |

|---|

The A-Star 328PB Micro provides access to all 24 I/O lines of the microcontroller and ships with an Arduino-compatible serial bootloader; you can also use an AVR in-system programmer (ISP) for access to the entire chip. We recommend our USB AVR Programmer v2, which supports both programming interfaces and can be configured to run at either 3.3 V or 5 V.

Last but not least, we are continuing our plan of offering new products at the highest quantity price break at single unit quantities as an introductory celebration. That means that for the first 100 customers, you can get an A-Star 328PB Micro for just $3.87! (Must use coupon code AS328PBINTRO; click to add the coupon code to your cart.)

While we assemble (and design and document and ship and support) the boards here in Las Vegas, we still get the bare PC boards from China, where they are currently on holiday celebrating Chinese New Year. That is constraining how many units we can make at the moment, so we are limiting shipments to 5 units per customer. However, the introductory coupon has no quantity limit, and you can order more than five at that price if you would like. Backordered units are likely to ship within a few weeks.

TI launches Robotics System Learning Kit (TI-RSLK) based on Pololu Romi platform

|

| Image from TI Robotics System Learning Kit introductory video courtesy of university.ti.com. |

|---|

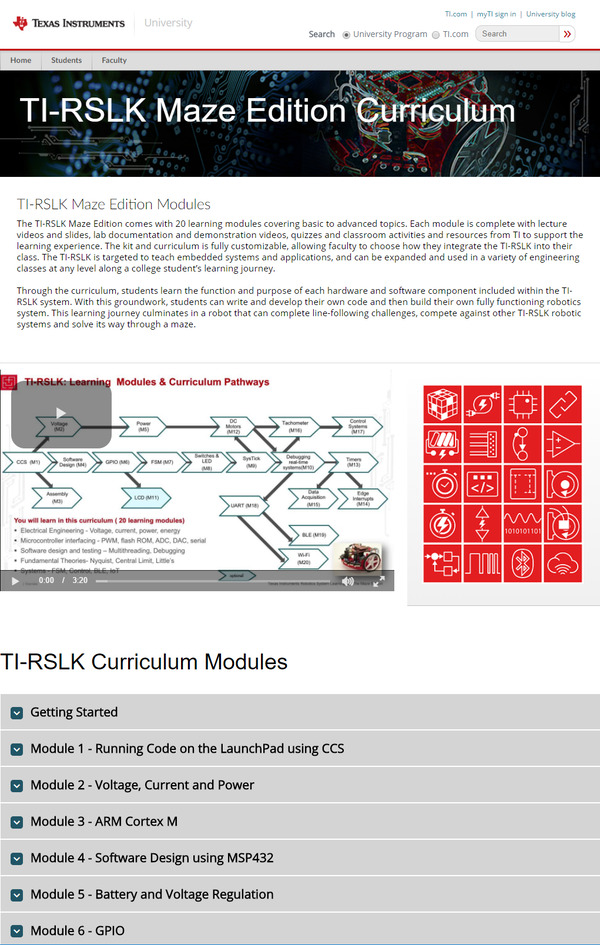

Texas Instruments just launched their new Robotics System Learning Kit (TI-RSLK), a complete robotics kit and curriculum aimed at university students and based on our Romi platform. Twenty modules with lecture notes, lab activities, and over a hundred videos are all publicly available now.

|

Image from TI Robotics System Learning Kit curriculum overview web page courtesy of university.ti.com. |

|---|

Several kits specifically for the course will be available soon through element14.

We are just starting to go through the ton of content ourselves since we were not directly involved in creating any of the course materials (except to the extent that TI used documentation from our products). We are excited about robotics and engineering education, and I am very interested to hear what you think of what TI is offering. Let me know, and I can pass your comments back to our contacts at TI, who of course are interested in the feedback, too.

|

Image from TI Robotics System Learning Kit introductory video courtesy of university.ti.com. |

|---|

The versatile Romi chassis is available in a variety of colors as just a mechanical kit for those who want to do all of their own electronics development. We also offer a growing selection of supporting electronics that include the Motor Driver and Power Distribution Board that TI is using in the TI-RSLK (along with their own microcontroller and LaunchPad modular development system). The more integrated Romi 32U4 Control Board includes an Arduino-compatible ATmega32U4 microcontroller and is ready for expansion with a Raspberry Pi or compatible embedded computer module.

How I picked our new machines (and what they mean for you!)

|

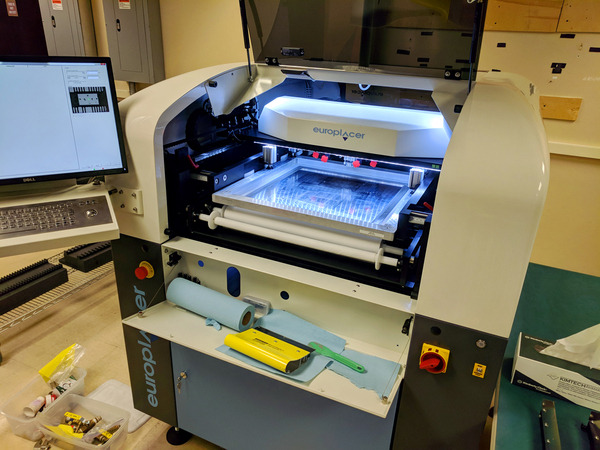

The new equipment I have been sharing for the past two weeks (here and here) represents our biggest manufacturing capacity increase in five years. Today I will go into more detail about the pick and place machine and stencil printer we got, along with what it means for our customers.

Assembling a circuit board with surface-mounted components involves three main steps: printing solder paste on a bare circuit board, placing the components on the board, and then sending the board through an oven, which melts the solder paste, soldering the components to the board. You can see the steps in this video we made a while ago about how the A-Star 32U4 Micro gets made:

Pick and place machine

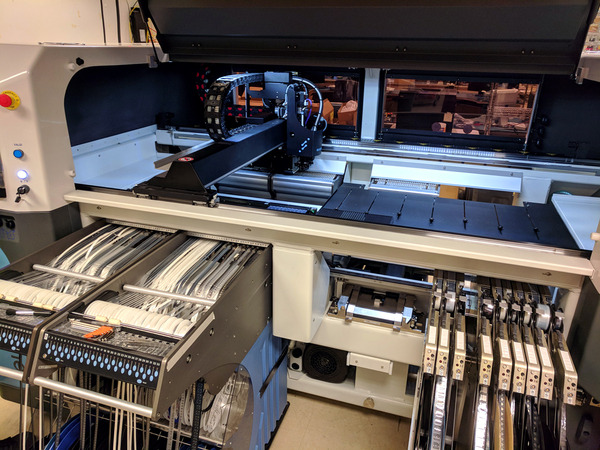

At the end of 2012, we got two very different pick and place machines, an SM421F from Samsung (which has since sold their electronics assembly equipment business to Hanwha) and an iineo from Europlacer. Both machines are very versatile, designed to place everything from the smallest components to large and tall parts, and we have run all of our products on both machines. I got both machines back then because each manufacturer made a compelling case, and I wanted to try both. The new machine we installed this month is another Europlacer machine. So… does that mean it’s better?

First off, the Europlacer machine is much bigger and more expensive than the Samsung/Hanwha machines, so the real comparison for this round of new equipment was two Hanwha machines vs. one from Europlacer. Each SM482 Plus has 120 feeder slots, so two of those machines have very similar feeder capacity to the 264 slots of the iineo+. The pair of Hanwha machines is also similar to the Europlacer option in terms of combined size and price. I should also say that we have had a great experience with both machines and vendors, and I do not regret having bought either of those machines in 2012. The Hanwha machine route had one major advantage: the machines, even individually, are faster than the Europlacer in the straight parts per hour component placement rate; with two of them, it should be no contest, with a combined advertised placement rate of around 60,000 components per hour vs. around 15,000 for the Europlacer machine. Having two smaller machines would also give us some more flexibility (we could operate them as two separate machines, running different products, as opposed to one big machine) and redundancy, so that we could keep at least some production running if one machine went down. The redundancy argument probably would have pushed me in the direction of the Hanwha, two-machine route, if we didn’t already have any other machines.

|

But we did already have a Europlacer machine, so getting a second one would give us that redundancy. And despite the sustained placement rate being four times lower, we expect the Europlacer to actually be the faster option for our purposes. That’s because our products tend to be relatively small and simple, but we have hundreds of different products (and I want it to be thousands soon), so we need to be able to run many different products a day efficiently. We might get some of that efficiency from the Europlacer software, though it’s not that clear to me that there really is that much difference between the machines (as opposed to operator familiarity). The interchangeable carts should also help eventually, though I do not expect that to make much of an impact until we have more of them, and so far we just have enough to basically fill each machine. What I think matters the most is the huge feeder count on a single machine, minimizing the amount of component changes that have to be made from one product to the next. It’s inevitable that the raw throughput will be lower when the placement head has to on average travel farther from the board being assembled to the part in the machine, but for our mix of quantities, it’s worth it.

|

132 feeder locations across four carts on the back side of the Europlacer iineo+ machine. There are 132 more on the other side! |

|---|

Stencil printer

For solder paste printing, I thought some more about a jet printer. The general idea is that the printer has the solder paste in a cartridge that moves all over the bare circuit board and squirts some on every pad, as opposed to squeegeeing a bead of solder paste through a stencil the way solder paste is more typically applied. I have been looking at MyData’s jet printers since they came out probably over ten years ago now, and the prospect of not needing stencils and being able to vary deposit thicknesses keeps being attractive, especially for our scenario where I want to be able to do just a few panels each of many different designs every day. But, at more than double the cost of a traditional stencil printer, the cost seems difficult to justify, especially since we cut our own stencils in-house. So, I ended up ordering another stencil printer from Europlacer since we are happy with the one we already have. MyData is now Mycronic, and you can see more about their jet printer at the Mycronic Jet Printer page.

|

The technician from Europlacer performing the installations was disappointed that we were pairing the nice new color-coordinated stencil printer with our Samsung pick and place machine. |

|---|

Commitment to better manufacturing and lower prices

What does all this mean for our customers? (Other than a higher likelihood of getting to see an awesome machine running when you come visit us.) Partly I am sharing this because I expect most of you like making things, like to see how things get made, and would love to have machines like this of your own. More importantly, I want to remind you of the effort we are going through to bring you better products at lower prices. Having more of this extremely flexible manufacturing capacity means we can keep churning out new prototypes quickly and then be able to manufacture the products at a globally competitive price. Over the coming months, we will be assessing our manufacturing costs and lowering prices on many of our popular products, and new products will have lower prices as soon as we introduce them.

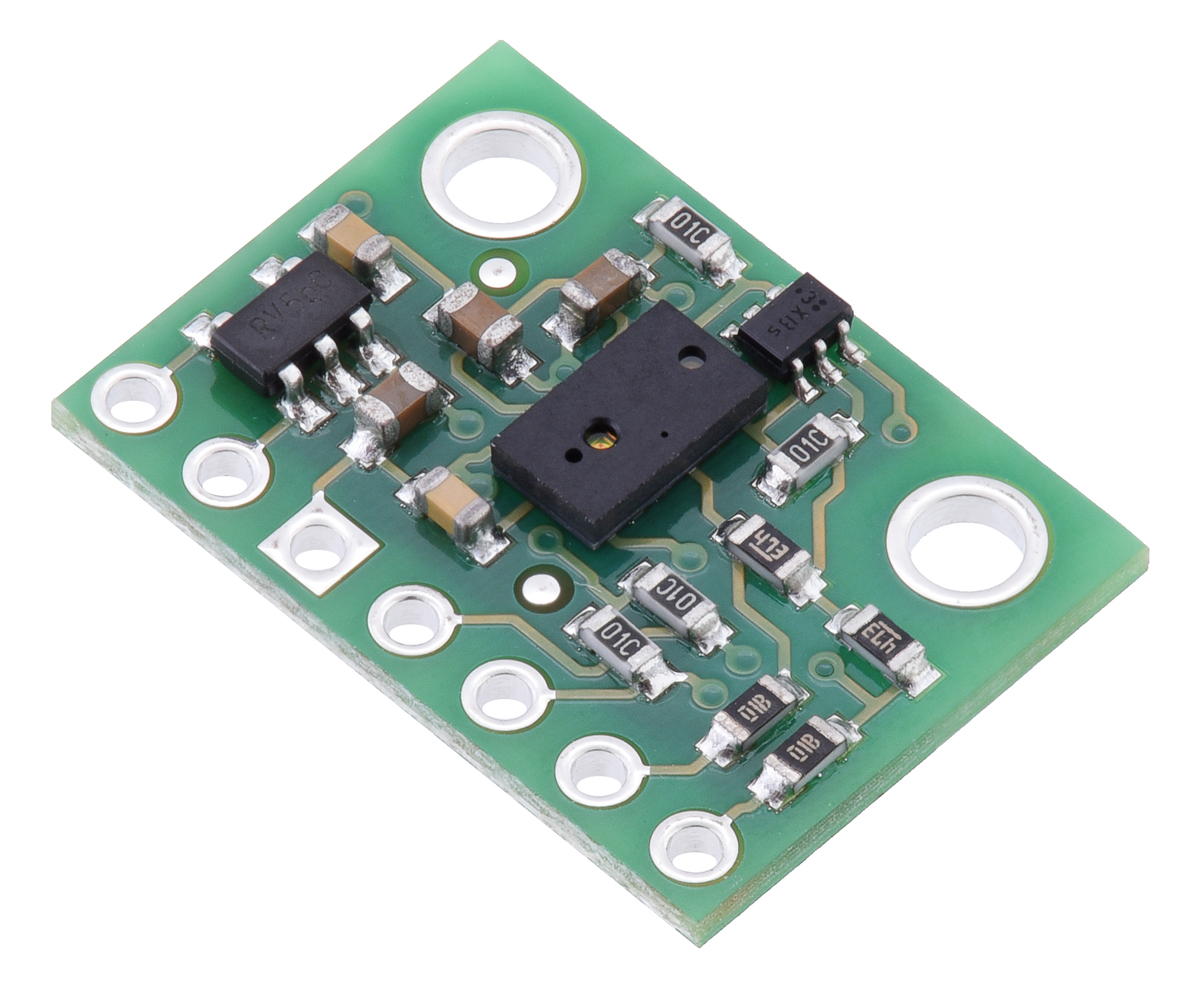

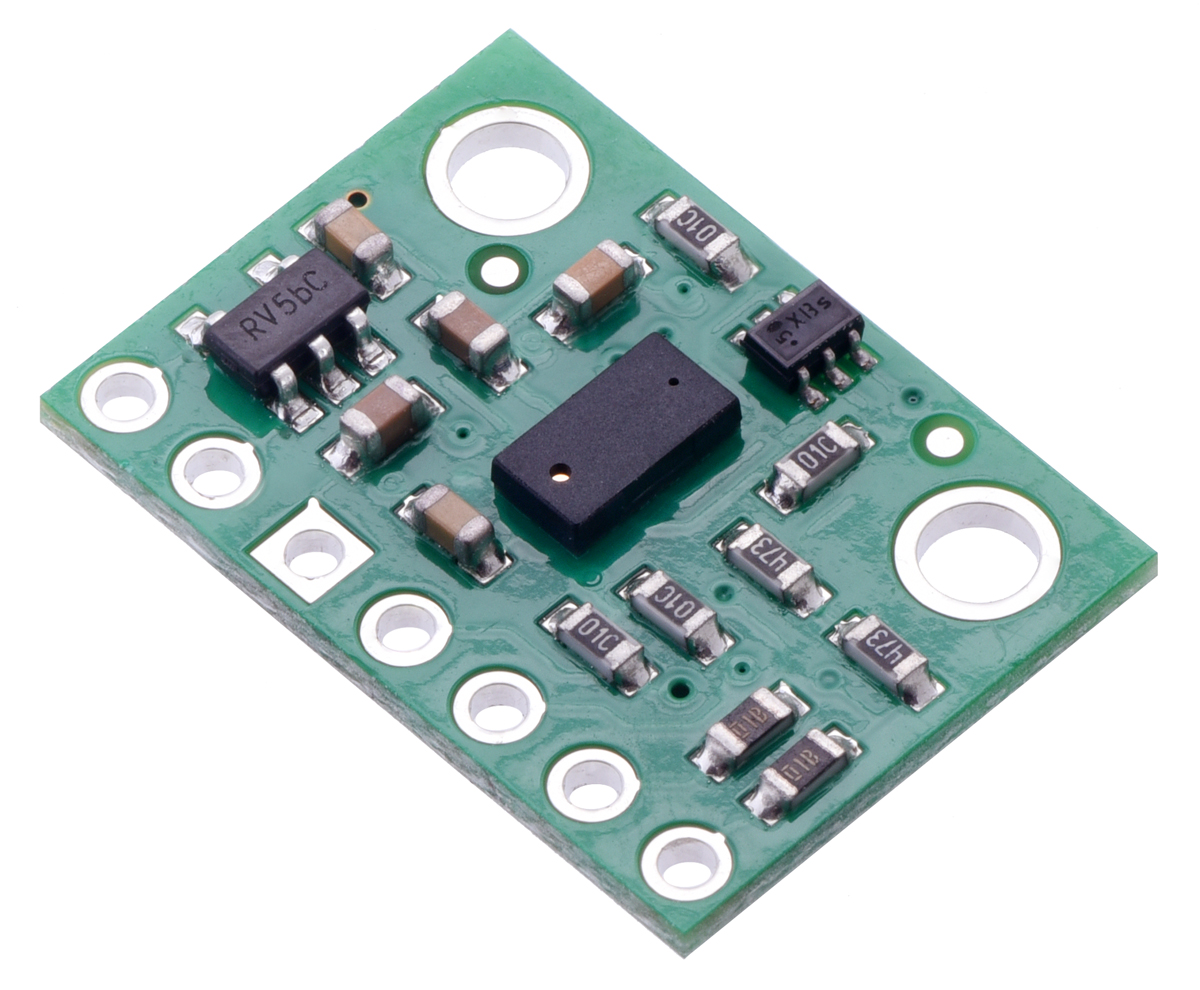

We are kicking that off with a substantial price cut on our popular time of flight distance sensors:

|

|

| VL6180X Time-of-Flight Distance Sensor Carrier with Voltage Regulator, 60cm max |

VL53L0X Time-of-Flight Distance Sensor Carrier with Voltage Regulator, 200cm Max |

And to help everyone share in our excitement, we’re offering the new, low, 100-piece pricing at single-unit quantities to the first 100 customers using coupon codes 2489PRICECUT and 2490PRICECUT (Click to add both coupon codes to your cart).

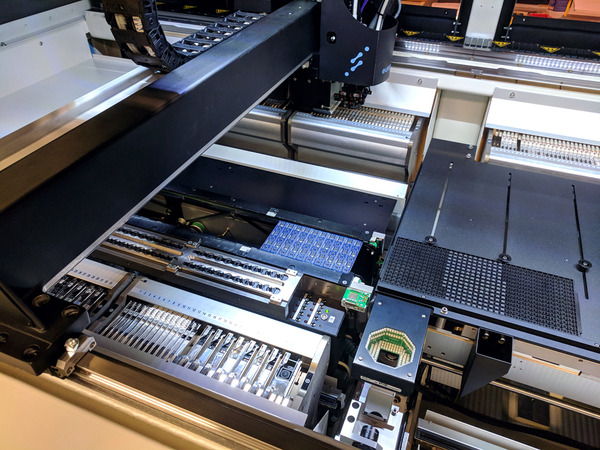

New equipment installation progress

Some more of our new equipment showed up yesterday, and installation has been progressing all week. Here are a few more pictures.

|

Stencil printer selfie! |

|---|

|

New Europlacer pick and place machine on the left, older one on the right. |

|---|

|

Stencil printer ready for first print. |

|---|

|

We like the Europlacer’s huge number of feeder slots. |

|---|

|

First production board on new Europlacer iineo+ pick and place machine, 7 February 2018. |

|---|

Europlacer’s iineo pick and place machine is one of the biggest and most versatile I know of, with space for up to 264 feeders (each feeder can hold a different component). For comparison, our Samsung pick and place machine, which itself has a decent feeder capacity compared to most machines, has 120 slots. We do not have any individual products that come close to requiring that many different components, but having such a huge feeder capacity means that we can run many different boards without having to change out a lot of parts. The feeders are also on carts that we can move around and between machines, which are also networked so that we can do things like set up new products on one machine and then run with the same setup on the other. I will write more soon about how this fits into our future plans, and about the other exciting new machine that is in the background of some of these pictures.

Picking and placing our new pick and place machine

We got a big delivery at Pololu yesterday. Here are some pictures for you to share in the excitement!

|

Seeing the truck pulling in with the crate on a flatbed trailer was a welcome sight after the difficulty last time, when we had to fish the crate lengthwise out of a covered trailer. |

|---|

|

|

Getting to uncrate the machine outside in short sleeves in January is just one of the perks of operating out of Las Vegas. |

|---|

|

|

|

|

Almost set for installation next week! |

|---|

I will post more about the machine and others we are installing once we have them up and running. For those of you wondering what it is, it is a pick and place machine, which is the kind of robot we use to build your robot parts. Here is a video of one of our existing machines in operation assembling a Zumo reflectance sensor array.

Free USA shipping on hundreds of Pololu metal gearmotors

Since my last post about free shipping in the USA, we expanded the program to include orders consisting of $40 or more in free add-on shipping items. And today, we added almost 300 different metal gearmotors to our selection of products that ship for free in the USA. (Don’t worry, we don’t pile up actual good production motors like we did in that picture; those were returned by an infamous, once-skyrocketing startup.)

New adjustable voltage regulators with multi-turn fine adjustment

|

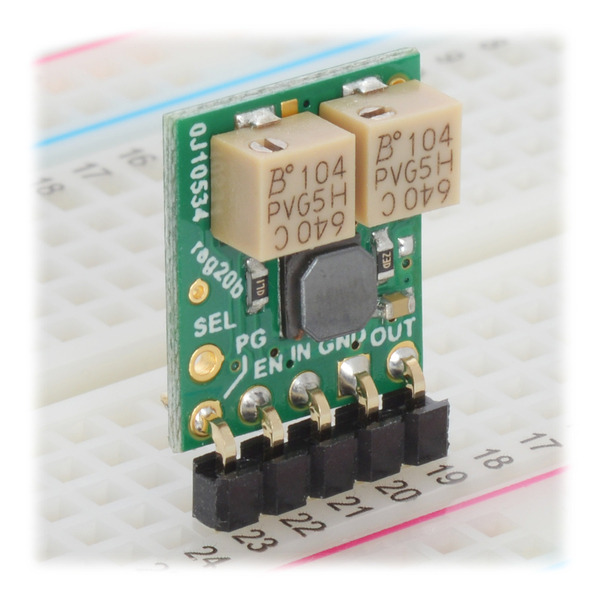

I am excited to announce our first voltage regulators with multi-turn trimmer potentiometers! I have wanted to add multi-turn pots to our products for a long time, but the problem has been that they are really expensive. They also tend to be quite big, at least compared to many of our boards, which we try to keep compact, and the smaller, surface-mounted ones are especially expensive. My latest round of looking for lower-cost options did not pan out, but I decided to just give it a try with the expensive parts.

The new S9V11x regulators that feature these potentiometers are buck-boost regulators that can output a voltage that is lower, the same, or higher than the input voltage. There are also versions with a multi-turn pot for adjusting the undervoltage cutoff threshold, so that if you use these with batteries, you can prevent overdischarging them. With twelve turns of adjustment available, it’s much easier to precisely set the voltages on the modules than with the single-turn potentiometers we have used on other adjustable regulators.

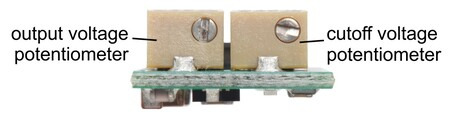

|

The output and cutoff multi-turn adjustment potentiometers on the S9V11x voltage regulators. |

|---|

While I have been talking mostly about the potentiometers, the main regulator is pretty magical, too, giving you quite a bit of power over a broad operating input range in a small size.

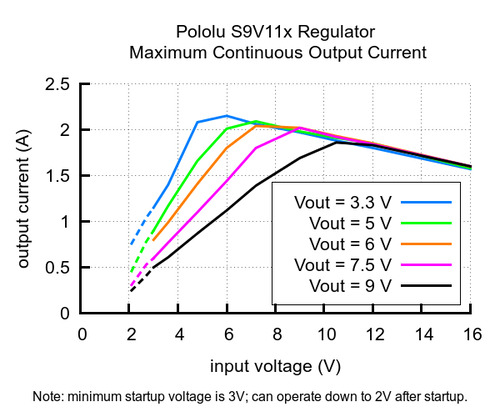

|

Typical maximum continuous output current of Step-Up/Step-Down Voltage Regulator S9V11x |

|---|

Our stock products are available in several combinations of adjustable and fixed output voltage and cutoff. If you have a higher-volume application, we can make them with fixed voltages wherever you need them. You could initially prototype your design with the adjustable version and then get fixed ones made once you know exactly what voltage you need.

| Regulator | Input (V) | Output (V) | Low-voltage cutoff | Size | Price | |

|---|---|---|---|---|---|---|

|

#2868 S9V11MACMA | 2* – 16 | 2.5 – 9 (fine-adjust) | fine-adjust | 0.50″ × 0.60″ × 0.25″ | $13.95 |

|

#2869 S9V11MA | 2.5 – 9 (fine-adjust) | – | $10.95 | ||

|

#2870 S9V11F5S6CMA | 5 (6 V selectable) | fine-adjust | $10.95 | ||

| #2871 S9V11F3S5CMA | 3.3 (5 V selectable) | fine-adjust | $10.95 | |||

|

#2872 S9V11F3S5 | 3.3 (5 V selectable) | – | 0.50″ × 0.60″ × 0.17″ | $7.95 | |

| #2873 S9V11F3S5C3 | 3.3 (5 V selectable) | 3 V (fixed) | $7.95 | |||

|

#2836 S9V11F5 | 5 | – | 0.30″ × 0.45″ × 0.17″ | $8.95 | |

| * The regulator has a minimum start-up voltage of 3 V, but it can operate down to 2 V after startup. It is disabled when the input voltage is below the low-voltage cutoff. | ||||||

I am very interested to see what people think of the multi-turn adjustment feature. If these new regulators sell decently or customers ask for it, we will add the multi-turn potentiometers to our other regulator offerings. Is the extra expense worth it? Or do you know of a good, low-cost, multi-turn potentiometer we could consider for future products like this?

Thanksgiving and preview of our upcoming Black Friday/Cyber Monday sale!

|

Some of my happiest memories of building Pololu, and therefore of my life, are of my friends Ben and Paul moving to Las Vegas to work on it with me. Ben was my best friend in high school, but we had not stayed in touch well after that. I met Paul at MIT, and he was involved with Pololu from the beginning, in 2000, and after he graduated, he visited Candice and me in Massachusetts and then in Las Vegas from time to time. Ben and I reconnected in late 2006, and he moved to Las Vegas shortly thereafter; Paul finally joined us (with his wife Fang) full time after the summer of 2007.

So we have been at this as a team for over ten years now. It’s long enough that it’s difficult to remember things being different. As I started writing this, I figured that our first Black Friday sale must have been in 2007, too. But apparently we did not have our first one until 2009 (though Ben pointed out, with a hint of resentment, that he might have been pushing for it sooner). I have happy memories of last-minute sale preparations and then staying up past midnight to watch the sales come in, wondering how long the doorbuster deals would last. Some years we were at home, instant-messaging each other; other years, we were at the office making sure everything worked as expected.

Even now, our Black Friday/Cyber Monday sale is probably the project Paul, Ben, and I work on together most intensely. There are of course others involved in getting ready for the sale, and there are lots of other projects the three of us all work on. But there’s a really hard deadline, which we typically do not have to deal with, which leads to late nights together. And preparing for the sale involves deciding which products we care about a lot and that we want to highlight, and since it’s our company, it’s our call on how much we want to push by offering products at or sometimes below cost, in the spirit of not only merchandising but also good fun. It’s a time to look back on the products we have released this year, and, as I am doing now, reminisce about Black Friday sales past.

|

(We do not recommend actually running a Balboa in the snow.) |

|---|

I am giving this background not only to share some of what I am thankful for, but to give our customers and newer employees some understanding of our perspective and what goes into these sales. It’s personal. It’s something fun for me, a kind of reversal of the excitement of looking for good deals as a shopper on Black Friday. When I used to be more directly involved in getting things made and shipped, I would usually go to stores in the evening, to see what deals might be left that other shoppers weren’t interested in. In the past few years, I’ve had the luxury of doing some brick and mortar Black Friday shopping in the morning, though usually I’m still shopping for things like vacuum cleaners for Pololu at stores like Home Depot.

We listen to what our customers say, and we try to put something in our deals for everyone. Of course, part of the point is to offer some extreme discounts, so we limit the quantities and the durations on those deals. But we still try to set the limits such that the doorbusters will last at least a few hours, so if you care and try a little, they should be available. If you’re one of those people who don’t like waking up early or sorting through special offers, I remind you that we work hard to offer good prices to begin with, and we are offering discounts site wide for the duration of the sale. And if you are a student or parent who really had your heart set on a Zumo or Balboa robot for Christmas but miss out on the doorbuster for some reason, and that extra discount makes the difference in being able to afford it, let us know. We want deserving people to have these robots, and we’ll try to help you out.

Now, on to details about the sale this year, since we will be making some big changes from years past. In a break from past years, when we had a single set of doorbuster coupons that went active on the first day of the sale and the same items were on sale for the duration of the sale (Wednesday before Thanksgiving through Cyber Monday), we will have different door busters for different days. We have also upgraded our coupon system so that we can control the time they are active, not just the day, so that we can make doorbusters go active at a time more appropriate for our customers in the United States.

Our new free shipping system should allow many of the sale items to ship for free or at a low cost, which should make it practical to make several orders over the course of the sale. We might combine some orders into single shipments to reduce our shipping expenses, but please note that because of the volume of orders we get during the sale, we will not be able to accommodate requests to combine orders to reduce shipping charges.

I hope you get to spend the holidays doing things that bring meaning to your life, with the people you love.

Oh, and if you were expecting to see a preview of the sale, it’s up on the Black Friday/Cyber Monday sale page now. Keep checking back throughout next week as we reveal more great deals!

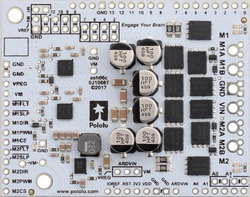

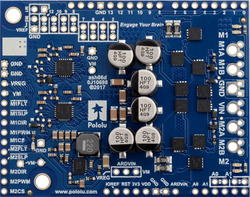

New product: Dual G2 High-Power Motor Drivers

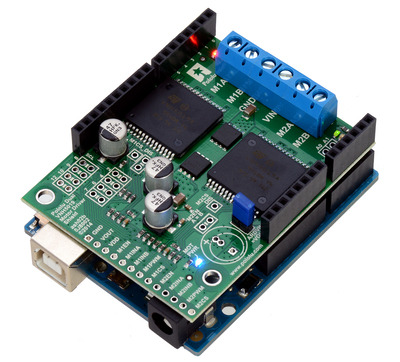

We sell a lot of motor drivers, which makes sense since you usually need motors to build robots, and motor drivers tend to be the kind of product you cannot really build yourself on a breadboard. One of our more popular products is the dual VNH5019 shield for the Arduino:

|

Pololu dual VNH5019 motor driver shield, assembled and connected to an Arduino Uno R3. |

|---|

That product is based on ST’s massive VNH5019 motor driver chip, which is a successor to the VNH3SP30 driver we initially started selling back in 2005:

|

Older version of the High-Current Motor Driver Carrier. |

|---|

When I first heard of the chip (at one of the first LVBots meetings), it seemed like someone must have misremembered the spec since it was inconceivable for a single integrated chip to deliver 30 amps. And to some extent, that was valid—you would have to do a lot of extra thermal management work to get 30 A out of that chip without it overheating. But the chip really could do in excess of 10 A, which was still amazing; the real limitation was in voltage, especially if you tried to use PWM at any moderate frequency. The VNH2SP30 was better about PWM frequency, letting us get to 20 kHz, but it had an upper operating limit of 16 V. The VNH5019 raised this to 24 V, getting us tantalizingly close to the 24V rail many would like to use. The problem is that 24 V is the limit, and we really need to be able to operate higher than that to account for the usual variations in nominally 24V power setups.

As far as I know, there is no integrated circuit that can deliver over ten amps at 24 V nominal (i.e. at least 30 V max); for that kind of power, you need to go to H-bridges with discrete MOSFETs. We have had those as stand-alone products for a while, too. But those still leave you with a lot of wiring to do if you want to drive two motors, which is typically the minimum for a mobile robot. The new product family we just released makes that easy by providing two high-power motor drivers in one Arduino shield-type package:

|

|

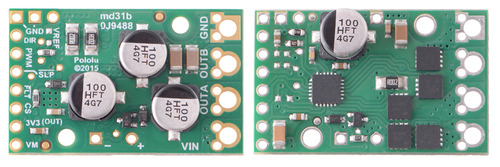

As you can see from the pictures, the main difference in these Dual G2 High-Power Motor Driver Shields is in the MOSFETs: the white boards have larger, 5×6mm MOSFETs, and the blue boards have smaller, 3×3mm MOSFETs. These correspond to the two versions of the individual drivers:

|

Pololu G2 High-Power Motor Driver 24v21 and 24v13. |

|---|

(The higher-power version on the left has the MOSFETs on the back side of the board.) We also offer each board with 30V and 40V MOSFETs, for four total options. The new dual motor drivers perform similarly to our single-channel G2 units, and like the single channel carriers, all of these dual drivers feature current sensing and an adjustable current limit that could be used to detect and protect against stall conditions. These are the individual performance points:

Dual G2 High- Power Motor Driver 18v22 Shield |

Dual G2 High- Power Motor Driver 18v18 Shield |

Dual G2 High- Power Motor Driver 24v18 Shield |

Dual G2 High- Power Motor Driver 24v14 Shield |

|

|---|---|---|---|---|

| Absolute max input voltage: |

30 V | 40 V | ||

| Max nominal battery voltage: |

18 V | 28 V | ||

| Max continuous current per channel: |

22 A | 18 A | 18 A | 14 A |

| Default active current- limiting threshold: |

60 A | 50 A | 40 A | |

| Current sense output: |

10 mV/A | 20 mV/A | ||

For drivers like these, power (heat) dissipation is generally the limiting factor. The copper area around the MOSFETs on both the white and blue versions of the drivers are about the same, so the lower-current blue units perform better then their smaller single channel G2 counter-parts, while the higher current white drivers do worse than the smaller single channel G2 carriers (which also use four layer PCBs for better performance). The power ratings we provide are the maximums without additional heat sinking or air flow and at room temperature. Please note that the boards will be extremely hot at those maximum currents, and the available current will be lower if the ambient temperature is higher.

Since many Arduino boards do not support higher input voltages, the new dual drivers also incorporate a 1A switching regulator so that a single higher-voltage supply can power the motors and Arduino. We have an Arduino library to help you get up and running quickly. And for those who want to use the board without an Arduino, all of the motor control connections are also brought out to a row of 0.1″ headers on one side of the board.

(And for those of you wanting to use this kind of driver with a Raspberry Pi, we have a Raspberry Pi HAT form-factor version coming soon!)