Pololu Blog » Engage Your Brain »

Big price reductions and new options for our popular stepper motor drivers

We recently substantially reduced prices on our stepper motor driver carriers, and I figured this announcement was a good time to give you an update on our perspective and capabilities.

|

The original A4983 Stepper Motor Driver Carrier. |

|---|

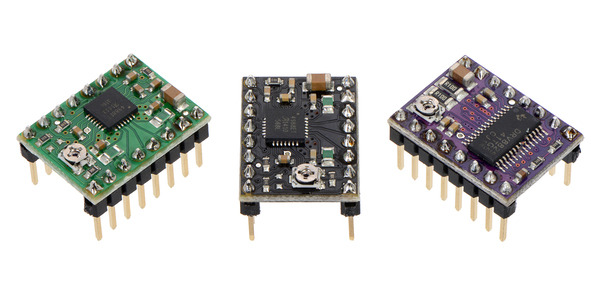

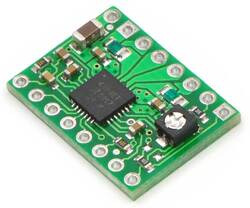

It has been over five years since I designed our original stepper motor driver carrier, which was for the A4983 from Allegro. While fairly straightforward, the implementation reflected several design philosophies that go into Pololu products, such as making the boards as small as practical and including the right extra components to make the main chip easily usable without unnecessarily limiting its features. One common internal discussion topic for new designs (and an occasional point of annoyed feedback from customers) is mounting holes, which some people argue for on just about every product. While we try to make carrier boards like these as generally usable as possible, we still try to have some idea of how they will be used and to make appropriate design decisions for those scenarios. In the case of these stepper motor drivers, the expectation was that these carriers would be used on breadboards or perfboards with standard 0.1″ grids, making mounting holes unnecessary as long as the electrical pins were spaced well. Adding the mounting holes would conflict with making the boards small, which would be a big benefit to anyone wanting to use multiple units within a larger design, as is common on multi-axis systems like CNC routers and 3D printers.

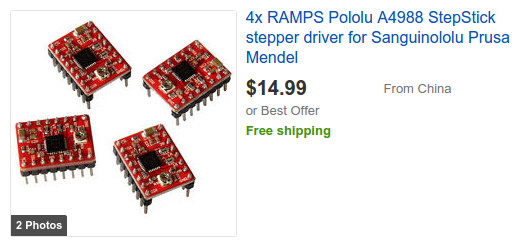

In what I see as validation of those design philosophies, the Pololu stepper driver carrier quickly became a standard (we’re the “P” in RAMPS). We have released several more stepper driver carriers that fit that same form factor, and many imitations have appeared, ranging from the more honest, open-source StepSticks to the less scrupulous knock-offs on eBay and various China-direct sources. Looking at pictures and descriptions of these units makes it clear that while there might be big variations in quality and support, the common theme among these copies is that they are cheap.

|

Typical eBay listing for Pololu stepper driver knock-offs (Pololu has never made a red stepper motor driver). |

|---|

The proliferation of these cheap motor drivers challenges us to consider our own values and priorities. I have been asked several times why we bother manufacturing boards ourselves rather than just outsourcing to contract manufacturers in China. For more expensive products or proprietary designs, it’s easier to have the general sense that our manufacturing costs are low enough and that any possible reduction in those costs are outweighed by considerations like production flexibility and better control of our products. But do we really want to compete with China in basic manufacturing of a product that is ultimately not that complicated and that has an open-source equivalent?

One of the challenges of manufacturing electronics on a small scale in Nevada is that a lot of the infrastructure supporting manufacturing in a place like Shenzhen is not here. That even extends to areas like attitudes toward component pricing. At least that is some of the story I get when I see products coming out of China with retail prices below what just the components would cost us. I spend a lot of my time ordering components, and though there is enough I have learned (and which was not covered at all in school) for a dedicated blog post, here is a short version of some of what is involved:

If I want to get better prices than what is publicly listed at sites like Mouser and Digi-Key (I have heard that the “ND” at the end of all their part names is for “no discount”, though I do not know if that’s true), I need to talk to someone who has the authority and the desire to haggle with me. Fortunately, that’s getting easier now that we’re spending millions of dollars a year. However, those people tend to be organized geographically, and someone responsible for sales in the southwestern United States is usually not interested in competing with prices in China. This leaves us with two options: (1) buy components through unauthorized channels, which I generally do not want to do for components like integrated circuits, or (2) convince the local manufacturer representatives and distributors that they should give us lower prices because we are trying to compete globally with products made in China. The main reason we are able to have this price cut that I am announcing here is that after hundreds of thousands of stepper drivers sold and years of talking to manufacturers like Allegro and TI, we have finally managed to negotiate substantial price reductions on these stepper drivers.

The main IC still represents most of our final product cost, but we have of course been working on reducing our costs of other components and of manufacturing. Some of those costs include individual packaging and the costs of keeping a lot of stock ready to ship, so we are trying a new approach of also offering the stepper drivers in bulk and without our usual same-day shipment commitment.

I am also happy to announce that we have also started to offer our stepper driver carriers with header pins already soldered on. Many of the cheap alternatives I mentioned earlier are offered this way, and we occasionally get requests for that. Through-hole soldering is something we have generally tried to limit since it is more difficult to automate. Also, my expectation is that soldering a few 0.1″ headers into a board is very quick and easy for most of our customers, so it’s not something we should be doing unless we can do it especially effectively. However, my long-term goal is to be improving our manufacturing capabilities, and these simple headers are an easy, low-risk way to get into more automated through-hole assembly.

For now, we are trying that with a soldering robot:

While there is something especially captivating about watching this robot solder your next robot’s parts, it is not yet clear whether this is actually an effective way to go about this. As you can see in the short clip, the robot is not particularly fast, and a person still has to load the pins and boards before the robot does its thing. My impression is that very few organizations use these robots, with most through-hole soldering getting done either by hand or with selective soldering systems that use small fountains of molten solder. As we ramp up through-hole production, we expect to get a better idea of whether we should be building a small army of soldering robots, opting for more conventional selective soldering machines, or just sticking with manual assembly.

This all brings me back to the question of whether we want to be competing with products made in China, and I think it’s clear the answer is yes. Our goal is to make great products, and price has to be part of that consideration. We don’t want to be making things that are just a penny cheaper than the DIY option or relying on better marketing and brand awareness; we want actual higher quality and lower prices. Ultimately, I would like everything we make to be a great product at a great price, and I hope our customers agree that we are making good progress in that direction.

2 comments

We had the same problem with the THT components and we bought a wave soldering machine last month, after some research what is the best solution.

http://youtu.be/kciPI46m_wI

You can cover the SMD parts with a peel able soldering mask or frame, so that the soldering wave do not get contact with the parts.

If you have some questions you can contact me via eMail.