This is a merged information page for Item #3097.

View normal product page.

Pololu item #:

3097

Brand:

Pololu

Status:

Active and Preferred

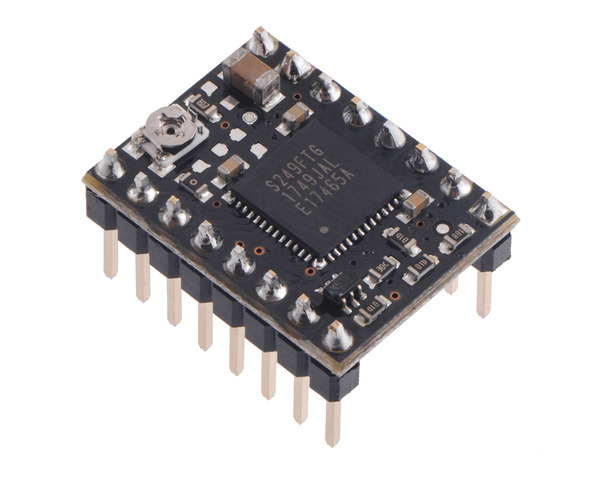

This version of our TB67S249FTG Stepper Motor Driver Compact Carrier ships with male header pins installed, so no soldering is required to use it with an appropriate 16-pin socket or solderless breadboard. The TB67S249FTG has a wide operating voltage range of 10 V to 47 V, and our carrier board can deliver approximately 1.6 A per phase continuously without a heat sink or forced air flow (up to 4.5 A peak). Please see the TB67S249FTG Stepper Motor Driver Compact Carrier product page for more information about the driver.

Alternatives available with variations in these parameter(s): continuous current per phase header pins soldered? Select variant…

Compare all products in TB67S2x9FTG Stepper Motor Driver Carriers or

Compare all products in TB67S2x9FTG Stepper Motor Driver Carriers or  16-pin Stepper Motor Drivers.

16-pin Stepper Motor Drivers.

|

TB67S249FTG Stepper Motor Driver Compact Carrier (Header Pins Soldered). |

|---|

|

TB67S249FTG Stepper Motor Driver Compact Carrier (top view). |

|---|

|

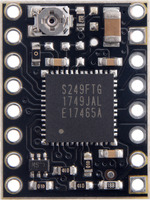

TB67S2x9FTG Stepper Motor Driver Compact Carrier, bottom view with dimensions. |

|---|

|

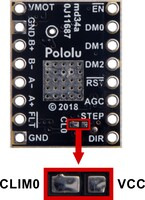

Bridge this SMT jumper with solder to change the AGC bottom limit from 60% to 80% on the TB67S2x9FTG Stepper Motor Driver Compact Carrier. |

|---|

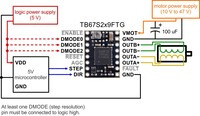

|

Minimal wiring diagram for connecting a microcontroller to a TB67S2x9FTG stepper motor driver compact carrier. |

|---|

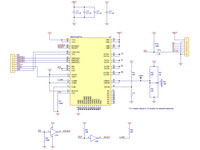

|

Schematic diagram of the TB67S249FTG/TB67S279FTG Stepper Motor Driver Compact Carrier. |

|---|

This version of our TB67S249FTG Stepper Motor Driver Compact Carrier ships with male header pins installed as shown in the main product picture, so no soldering is required to use it with an appropriate 16-pin socket or solderless breadboard. Please see the TB67S249FTG Stepper Motor Driver Compact Carrier product page for more information about the driver.

| Size: | 0.6″ × 0.8″ |

|---|---|

| Weight: | 2.6 g |

| Motor driver: | TB67S249FTG |

|---|---|

| Minimum operating voltage: | 10 V |

| Maximum operating voltage: | 47 V |

| Continuous current per phase: | 1.6 A |

| Maximum current per phase: | 4.5 A |

| Minimum logic voltage: | 2 V |

| Maximum logic voltage: | 5.5 V |

| Microstep resolutions: | full, non-circular 1/2, 1/2, 1/4, 1/8, 1/16, 1/32 |

| Current limit control: | potentiometer |

| Reverse voltage protection?: | N |

| Header pins soldered?: | Y |

| PCB dev codes: | md34a |

|---|---|

| Other PCB markings: | 0J11687 |

This DXF drawing shows the locations of all of the board’s holes.

Toshiba’s product page for the TB67S249FTG stepping motor driver IC, with links to its most up-to-date datasheet in several languages, application notes, and other resources.

Toshiba’s product page for the TB67S279FTG stepping motor driver IC, with links to its most up-to-date datasheet in several languages, application notes, and other resources.

Yes. To avoid damaging your stepper motor, you want to avoid exceeding the rated current, which is 600 mA in this instance. All of our stepper motor drivers let you limit the maximum current, so as long as you set the limit below the rated current, you will be within spec for your motor, even if the voltage exceeds the rated voltage. The voltage rating is just the voltage at which each coil draws the rated current, so the coils of your stepper motor will draw 600 mA at 3.9 V. By using a higher voltage along with active current limiting, the current is able to ramp up faster, which lets you achieve higher step rates than you could using the rated voltage.

If you do want to use a lower motor supply voltage for other reasons, consider using our DRV8834 or STSPIN-220 low-voltage stepper motor drivers.

Yes, you do! Setting the current limit on your stepper motor driver carrier before connecting your motor is essential to making sure that it runs properly. An appropriate current limit also ensures that your motor is not allowed to draw more current than it or your driver can handle, since that is likely to damage one or both of them.

Setting the current limit on this stepper motor driver is done by adjusting the on-board potentiometer. We strongly recommend using a multimeter to measure the VREF voltage while setting the current limit so you can be sure you set it to an appropriate value (just turning the pot randomly until things seem to work is not a good approach). The following video has more details on setting the current limit:

No blog posts to show.