Mechanical Components » Motors and Gearboxes » Stepper Motors »

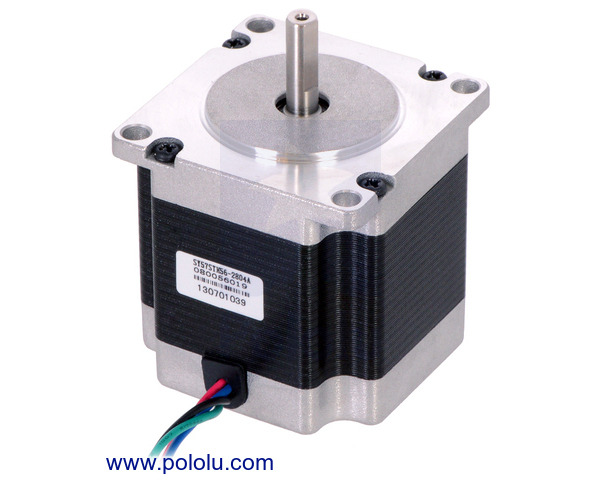

Stepper Motor: Bipolar, 200 Steps/Rev, 57×56mm, 2.5V, 2.8 A/Phase

This NEMA 23-size hybrid bipolar stepping motor has a 1.8° step angle (200 steps/revolution). Each phase draws 2.8 A at 2.5 V, allowing for a holding torque of 13 kg-cm (180 oz-in).

Compare all products in Stepper Motors or

Compare all products in Stepper Motors or  NEMA 23 Stepper Motors.

NEMA 23 Stepper Motors.

| Description | Specs (13) | Pictures (6) | Resources (2) | FAQs (2) | On the blog (0) |

|---|

|

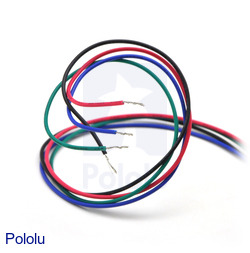

Bipolar stepper motor wires are terminated with bare leads. |

|---|

|

Bipolar stepper motor wiring diagram. |

|---|

Overview

This high-torque hybrid bipolar stepping motor has a 1.8° step angle (200 steps/revolution). Each phase draws 2.8 A at 2.5 V, allowing for a holding torque of 13 kg-cm (180 oz-in). The motor has four color-coded wires terminated with bare leads: black and green connect to one coil; red and blue connect to the other. It can be controlled by a pair of suitable H-bridges (one for each coil), but we recommend using an appropriately powerful bipolar stepper motor driver, such as our High-Power Stepper Motor Driver 36v4, or our Tic 36v4 High-Power Stepper Motor Controller. In particular, the Tic makes control easy because it supports six different interfaces (USB, TTL serial, I²C, RC, analog voltages, and quadrature encoder) and is configurable over USB with our free configuration utility.

|

NEMA 23 stepper motor (item #1475) mounted with a steel L-bracket for NEMA 23 stepper motors. |

|---|

Our 1/4″ universal mounting hub and 1/4″ scooter wheel adapter can be used to mount objects on the stepper motor’s 1/4″-diameter output shaft, and we carry a NEMA 23 steel bracket for securely mounting this stepper motor to a flat surface (the picture above shows this bracket being used with a taller NEMA 23 stepper motor).

Specifications

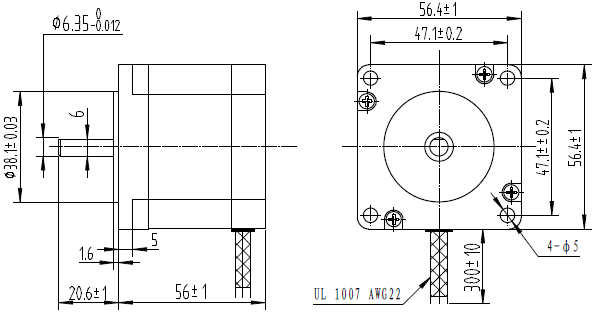

- Size: 56.4 mm square × 56 mm, not including the shaft (NEMA 23)

- Weight: 0.7 kg (25 oz)

- Shaft diameter: 6.35 mm (0.25″) “D”

- Steps per revolution: 200

- Current rating: 2.8 A per coil

- Voltage rating: 2.5 V

- Resistance: 0.9 Ω per coil

- Holding torque: 13 kg-cm (180 oz-in)

- Inductance: 2.5 mH per coil

- Lead length: 30 cm (12″)

- Output shaft supported by two ball bearings

More specifications are available in the datasheet (49k pdf).

Dimensions

The following diagram shows the stepper motor dimensions in mm. The output D-shaft has a 0.25″ (6.35 mm) diameter with a section that is flattened by 0.5 mm (note: the diagram below incorrectly lists this flattened width as 6 mm when it is really 5.85 mm). This shaft works with our 1/4″ universal mounting hub and 1/4″ scooter wheel adapter.

|

|

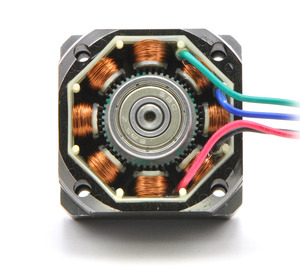

The inside of a bipolar stepper motor (SOYO NEMA 14-size). |

|---|

Stepper Motor Applications

Stepper motors are generally used in a variety of applications where precise position control is desirable and the cost or complexity of a feedback control system is unwarranted. Here are a few applications where stepper motors are often found:

- Printers

- CNC machines

- 3D printer/prototyping machines (e.g. RepRap)

- Laser cutters

- Pick and place machines

- Linear actuators

- Hard drives

|

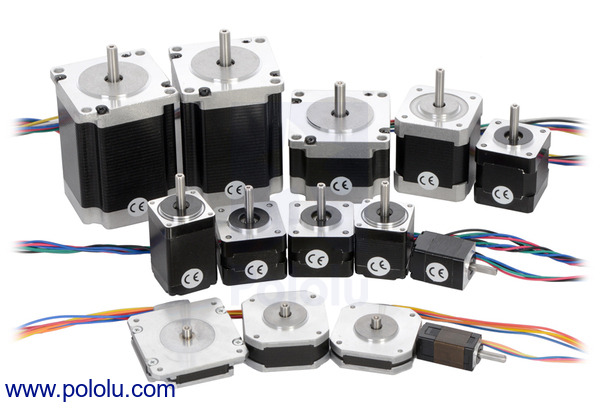

Pololu’s assortment of stepper motors. |

|---|

Note: This stepper motor is SOYO part number SY57STH56-2804A.

People often buy this product together with:

|

Pololu Universal Aluminum Mounting Hub for 1/4″ (6.35mm) Shaft, #4-40 Holes (2-Pack) |

|

Stepper Motor: Bipolar, 200 Steps/Rev, 42×38mm, 2.8V, 1.7 A/Phase |

|

Steel L-Bracket for NEMA 23 Stepper Motors |