Support » Pololu TReX User’s Guide » 3. Getting Started »

3.a. Motor and Power Connections

The TReX receives its power through the VIN/GND connector terminals. VIN should be between 6 and 16 V and your power source must be able to supply the current your motors will be drawing. The TReX can supply peaks of 30 A and up to a continuous 13 A to each of its two bidirectional motors under typical conditions. Performance will depend on the actual system and its ability to dissipate heat. The TReX’s bottom motor driver board is designed to help heat flow away from the VNH2SP30 motor driver chips, but addition of a heat sink and good air flow can further improve performance. The TReX can supply up to 15 A (continuous) to the auxiliary motor.

There are several different ways to connect motors to your TReX:

Option 1:

|

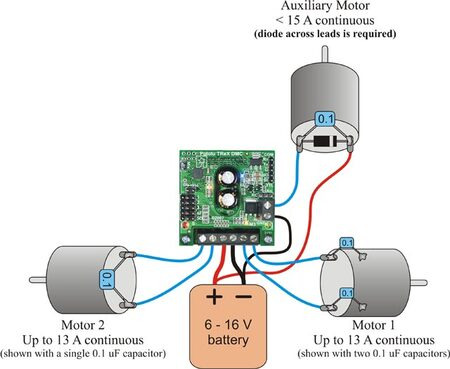

TReX motor connections (single battery) |

|---|

The figure above demonstrates how to connect two bidirectional motors and a unidirectional auxiliary motor to your TReX, all powered by the same battery. Note that the auxiliary motor is driven by permanently connecting one lead to power while the board PWMs the other lead between high impedance and ground. You must connect your battery’s ground directly to the lower port of the auxiliary motor’s connection block if you plan to use the auxiliary motor. Otherwise, the auxiliary motor could attempt to pull too much current through the TReX itself, thereby damaging the unit.

The auxiliary motor’s other lead connects to the upper port of its connection block. You will need to connect a diode across the auxiliary motor’s terminals as shown below. Failing to do so will adversely affect the performance of your TReX and could result in permanent damage to the device. Take great care to ensure you do not solder the diode in backwards! You should not solder a diode to your bidirectional motors.

You may find it beneficial to solder 0.1uF capacitors across all of your motors’ terminals. This will decrease the noise put out by your motors and can improve performance of your TReX. You can further decrease the noise put out by your motors by keeping their leads as short as possible and twisting them around each other in a helix.

Option 2:

|

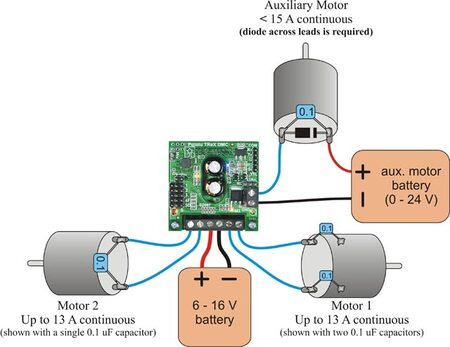

TReX motor connections (separate battery for the auxiliary motor) |

|---|

It is possible to power the auxiliary motor with a second, separate 0 – 24 V battery, as shown above. To do so, connect that battery’s ground to the lower of the two auxiliary motor connection block ports. Connect one of your auxiliary motor’s leads to the upper connection block port and connect the other of your motor’s leads directly to the battery’s positive side. You will still need to solder a diode across your auxiliary motor’s terminals.

Option 3:

|

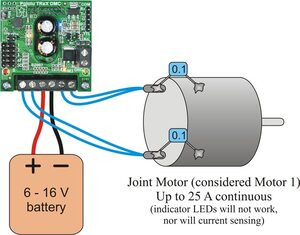

TReX joint-motor connection |

|---|

Lastly, you can use both motor 1 and 2 outputs to control a single, more powerful (up to 25 A continuous) bidirectional motor by connecting it as shown above. One of the motor’s terminals connects to both of motor 1’s outputs while the other of the motor’s terminals connects to both of motor 2’s outputs. In order to use your TReX in this way, you must use the serial interface to set the TReX to “joint motor mode”. In this mode, the single bidirectional motor is considered “motor 1”. The motor speed/direction indicator LEDs will not work in this mode, nor will current sensing or channel mixing. Although it is not shown in the figure above, you can additionally control an auxiliary motor while running in “joint motor mode”.