Pololu Blog »

USB connectors: Mini or Micro?

|

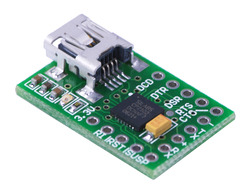

Pololu USB-to-serial adapter. |

|---|

When we designed the first version of the Pololu USB-to-serial adapter way back in 2004, using a USB Mini-B receptacle was an obvious choice: it was much smaller than the standard B-type connector, allowing us to keep the board compact, and it was readily available in surface-mount configurations that facilitate automated printed circuit board assembly.

We went on to use the Mini-B connector in lots of products, like our Maestro servo controllers and Wixel. Although the even smaller Micro-B connector became part of the USB specification in 2007, it didn’t seem to offer enough of an advantage over the Mini-B connector for us to immediately switch over.

|

CP2104 USB-to-serial adapter carrier. |

|---|

However, the Micro-B connector has become ubiquitous over the past few years, especially with its widespread adoption in cell phones and tablets. Since that means the typical person is more and more likely to have a Micro-USB cable, it’s no surprise that many other electronic products are now using Micro-B as well. The designers of the Raspberry Pi even chose the Micro-B receptacle as their power input jack, for reasons they explained in this blog post.

So when we made a new CP2104-based serial adapter last year, we decided to try putting a Micro-B connector on it. But does that mean we’re done with Mini-B? There are still a few other factors to think about.

One initial reservation we had about the Micro-B connector was that it seemed potentially more fragile than its Mini-B counterpart. Because it’s so much smaller, we thought it might be easier to accidentally twist or pull the Micro-B connector off a board, which is a failure we’ve occasionally seen with our Mini-B connectors. As a result, we chose a Micro-B receptacle design that we hope will offer more resistance to being pried off the board: its shell has four “legs” that are soldered into plated through holes in the board, whereas our older Mini-B connector only had four “feet” that are soldered onto surface-mount pads.

|

Bottom side of the CP2104 serial adapter carrier, showing the through holes into which the Micro-B connector is soldered. |

|---|

Additionally, the Micro-B connector offers other mechanical advantages over Mini-B, at least on paper. The Micro-B connector is rated for 10,000 insertion/extraction cycles as opposed to the Mini-B connector’s 5,000, and Micro-USB plugs include a latching mechanism that hooks into the receptacle to help prevent it from working loose. With the spring contacts transferred from the receptacle to the plug, Micro-B is also supposed to make bad connections easier to fix; the idea is that instead of the USB device’s connector wearing out, the plug will wear out on the cable instead, which is more easily replaced.

Designing a USB product with a Micro-B connector does require extra consideration to ensure that it can be manufactured correctly. In particular, the Micro-B receptacle includes a flange around its perimeter that helps guide a plug into the correct position when inserted. (Flangeless connectors exist, but they’re intended to be used in enclosures where the opening guides the plug into the receptacle.) As the flange extends not only past the edge of the board but also below the level of the board surface (on which the connector shell rests), a board designed with a Micro-B connector must be panelized with routed slots between rows to accommodate the connector overhang.

|

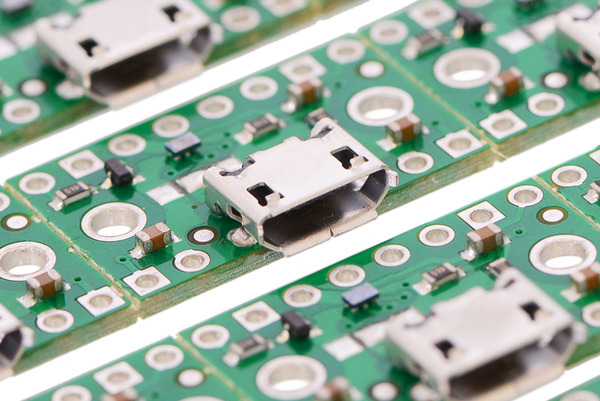

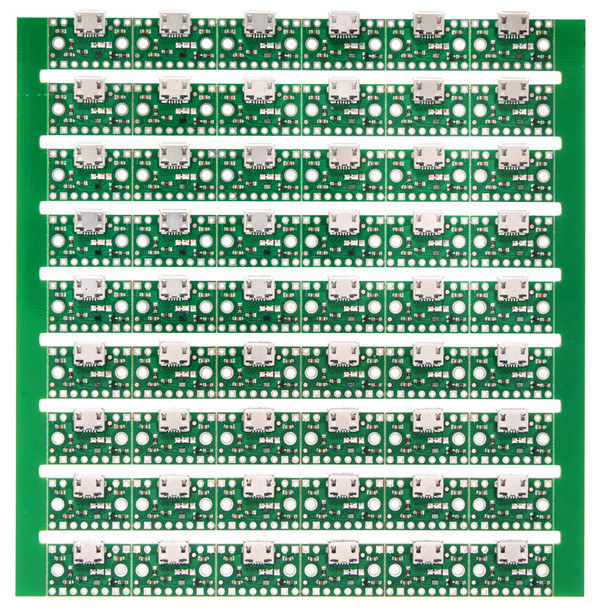

A close-up of an overhanging USB Micro-B connector on a panel of FPF1320 power multiplexer carriers. |

|---|

These slots can be easily seen in the panel of FPF1320 power multiplexer carriers pictured here. By contrast, panelizing a design with a Mini-B connector is much simpler: while the Mini-B receptacle also extends past the edge of the board, it sits flush with the board surface. As long as there’s room at the bottom of each board to accommodate the overlap of the connector from the next board down, the boards can simply be arranged in a contiguous grid with V-scores like most other designs.

|

A full panel of FPF1320 power multiplexer carriers, showing the routed slots necessary to accommodate the flanges on the USB Micro-B connectors. |

|---|

We’re interested to hear any thoughts you might have about these USB connectors. Which type is easier to use? Have you had any problems with connectors failing or coming off boards? What would you prefer to see on our future products? Leave a comment and let us know what you think.